Cold and hot shearing edge steel for shearing thick plate

A technology of cutting blade steel and blade steel, which is applied in the field of ferrous metallurgical alloy steel cutting tool materials, can solve the problems of low wear resistance, poor toughness, and restricting the service life of cutting blades, and achieve long service life, high impact toughness, and not easy to collapse blade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

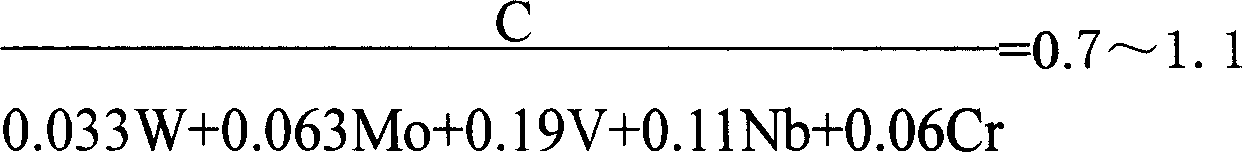

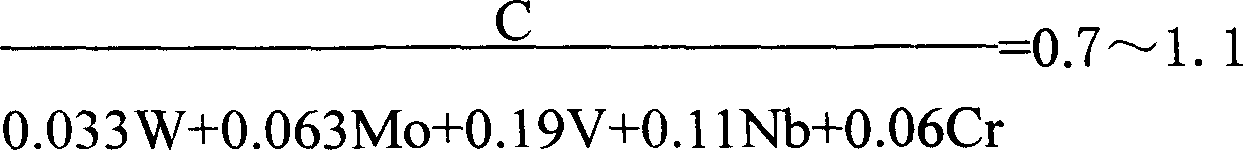

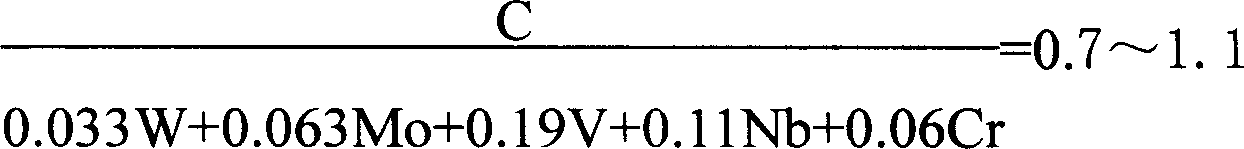

[0031] Let’s try to give a kind of cold and hot shear dual-purpose shear blade steel——HMB steel, according to the composition of alloy elements (Wt%): C: 0.35~0.60, Si: 0.25~1.50, Mn: 0.25~1.50, Cr: 3.00~7.00, W: 1.00-3.50, Mo: 1.00-4.50, V: 0.50-3.00, Nb: 0.50-3.00, Re: 0.05-0.15, Cu: ≤0.050, P: ≤0.025, S: ≤0.025, and the remainder is Fe. Within the above composition range, the content of main alloying elements and carbon should match each other according to the following formula:

[0032] C 0.033 W + 0.063 Mo + 0.19 V + 0.11 Nb + 0.06 Cr = 0.7 ~ 1.1

[0033] According to the composition and matching relationship of the alloying elements, the total content coefficient of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com