Automatic regulating device for gas induction error

An automatic adjustment device and gas technology, applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problems of error adjustment limit, change, sensor characteristic value change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

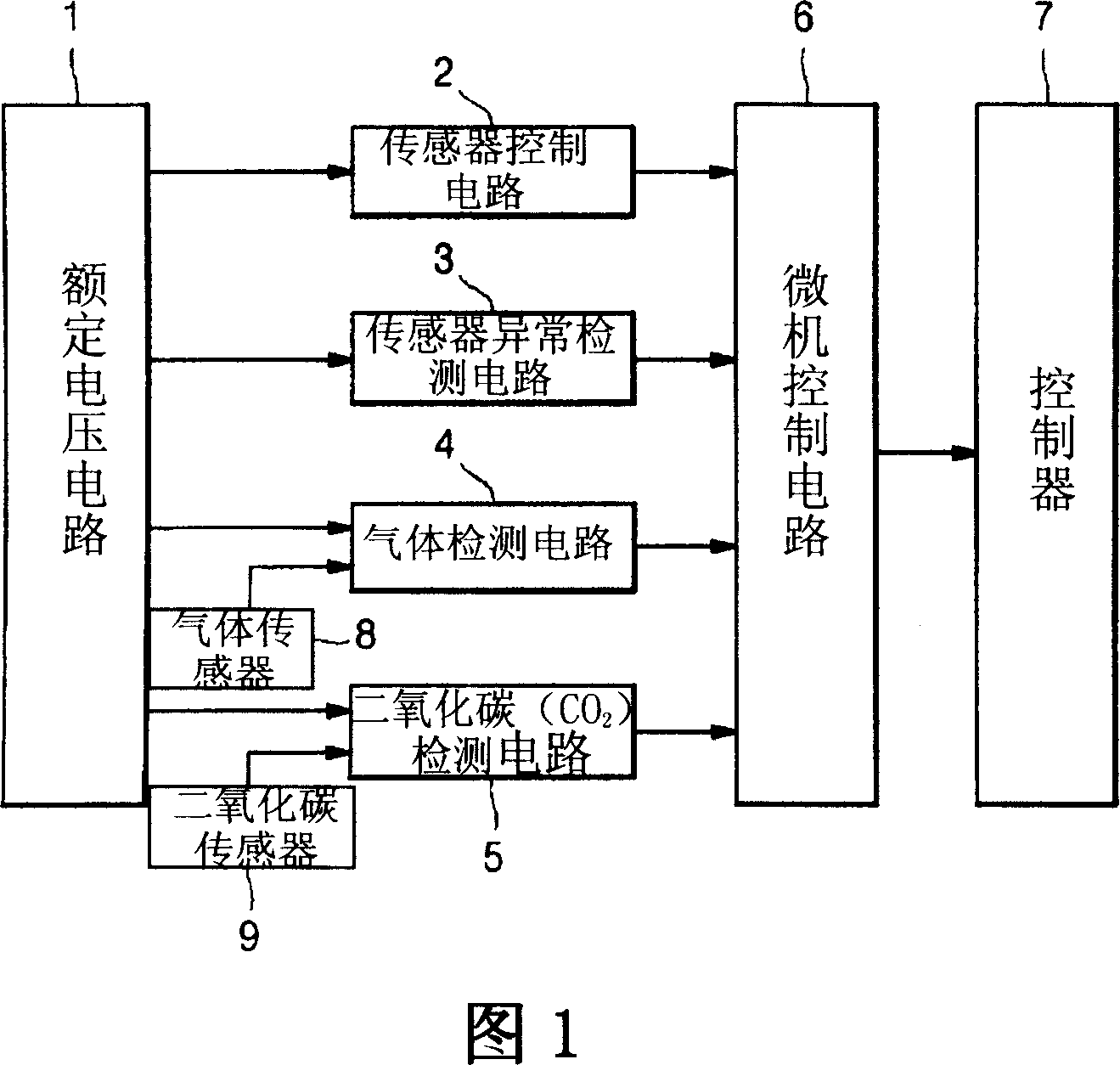

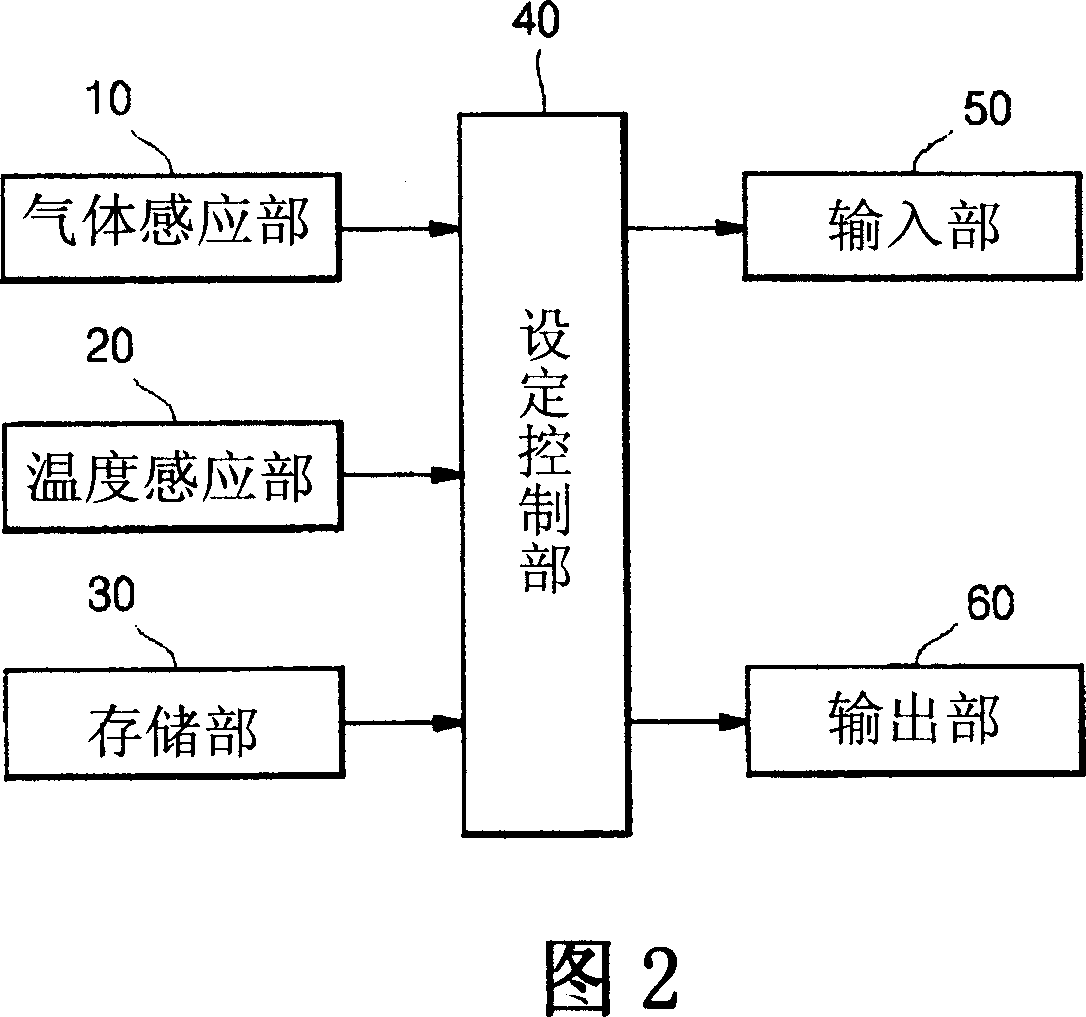

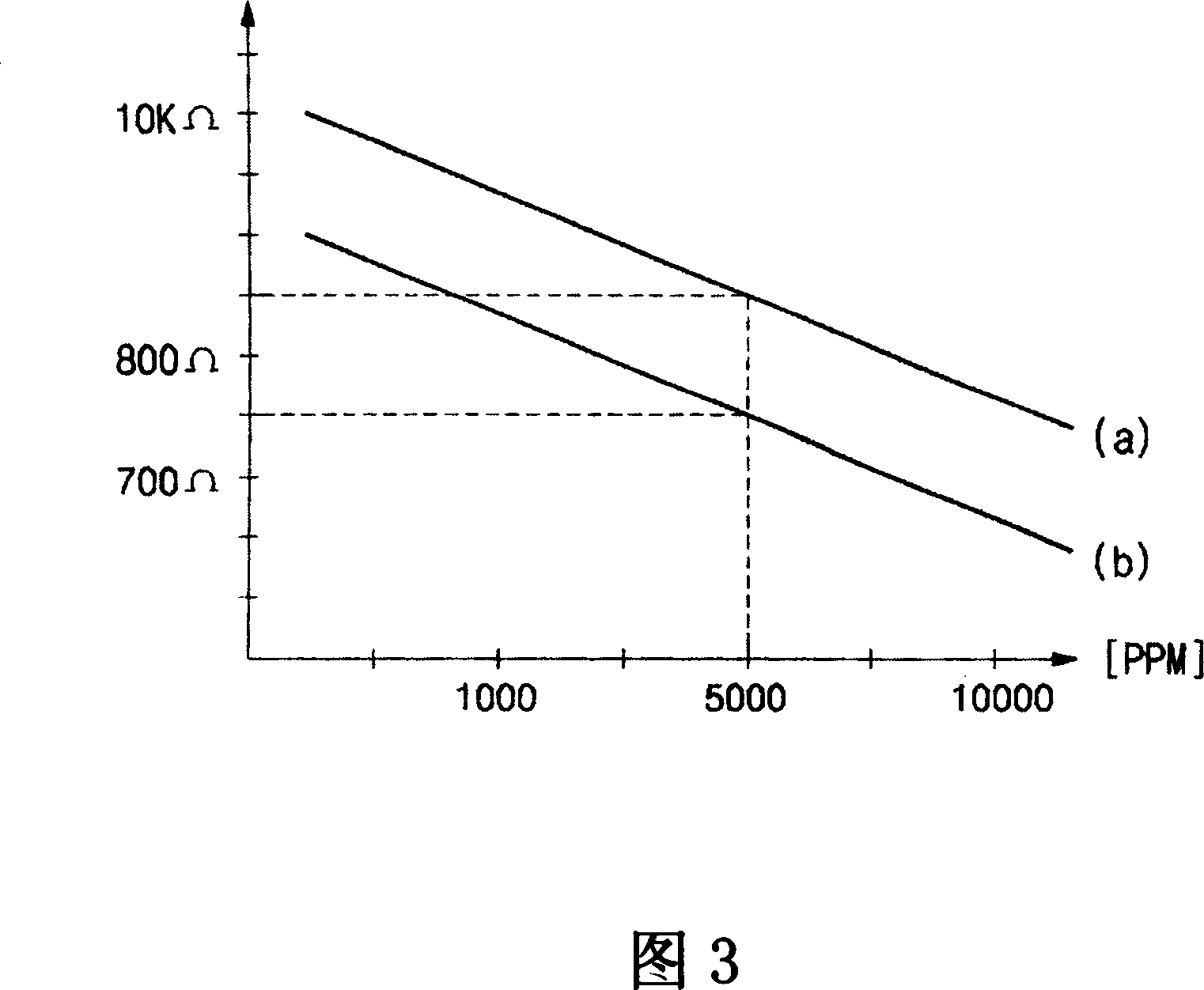

[0019] FIG. 2 is a block diagram of an automatic error adjustment device for a gas sensor of a gas sensing device according to an embodiment of the present invention, and FIG. 3 is a graph showing measurement for setting an existing error value of a gas sensor.

[0020] The present invention relates to a device capable of automatically adjusting the error caused by the inherent resistance value of a gas sensor of a gas sensing device. As shown in Figure 2 and Figure 3, the device is connected with: a gas sensing part 10, connected with a gas sensor for sensing gas; a temperature sensing part 20, connected with a temperature sensor; a storage part 30, connected with a stored gas sensor The memory device of the standard value and the error value; the input unit 50 can select the input condition mode required for adjusting the induction error of the gas sensor; the setting control unit 40 is used to input the gas sensing unit 10, the temperature sensing unit 20, the storage unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com