Linear motor and linear compressor using the same

A linear motor and linear reciprocating motion technology, which is applied in the direction of compressors, engine working fluid, engine components, etc., can solve the problem of effectively controlling the forward/backward swing of magnets, increasing the amount of magnets, and increasing self-resistance, etc. problems, to achieve the effect of easy control of the stroke, reduced dosage, and minimized self-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

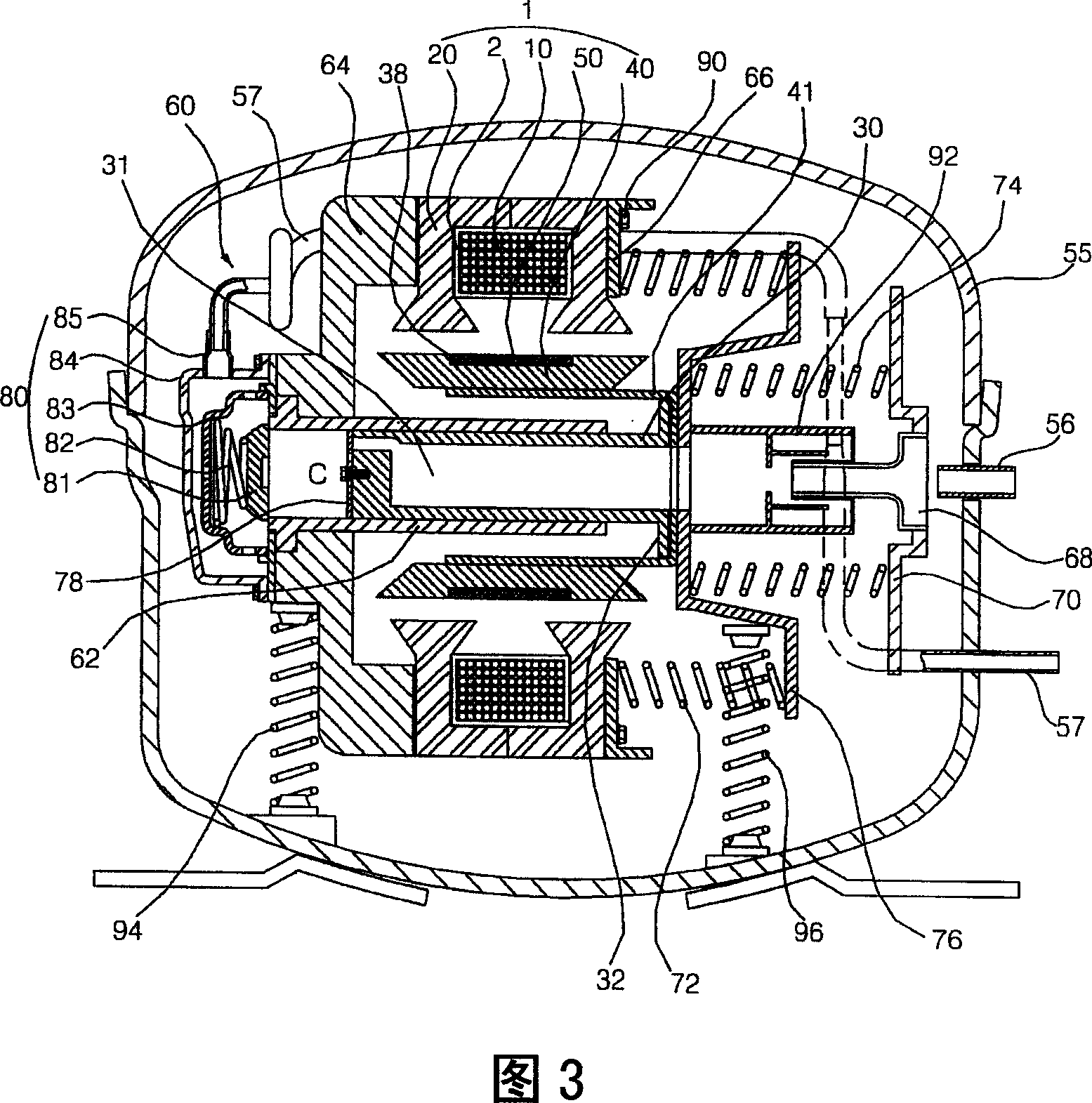

[0036] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

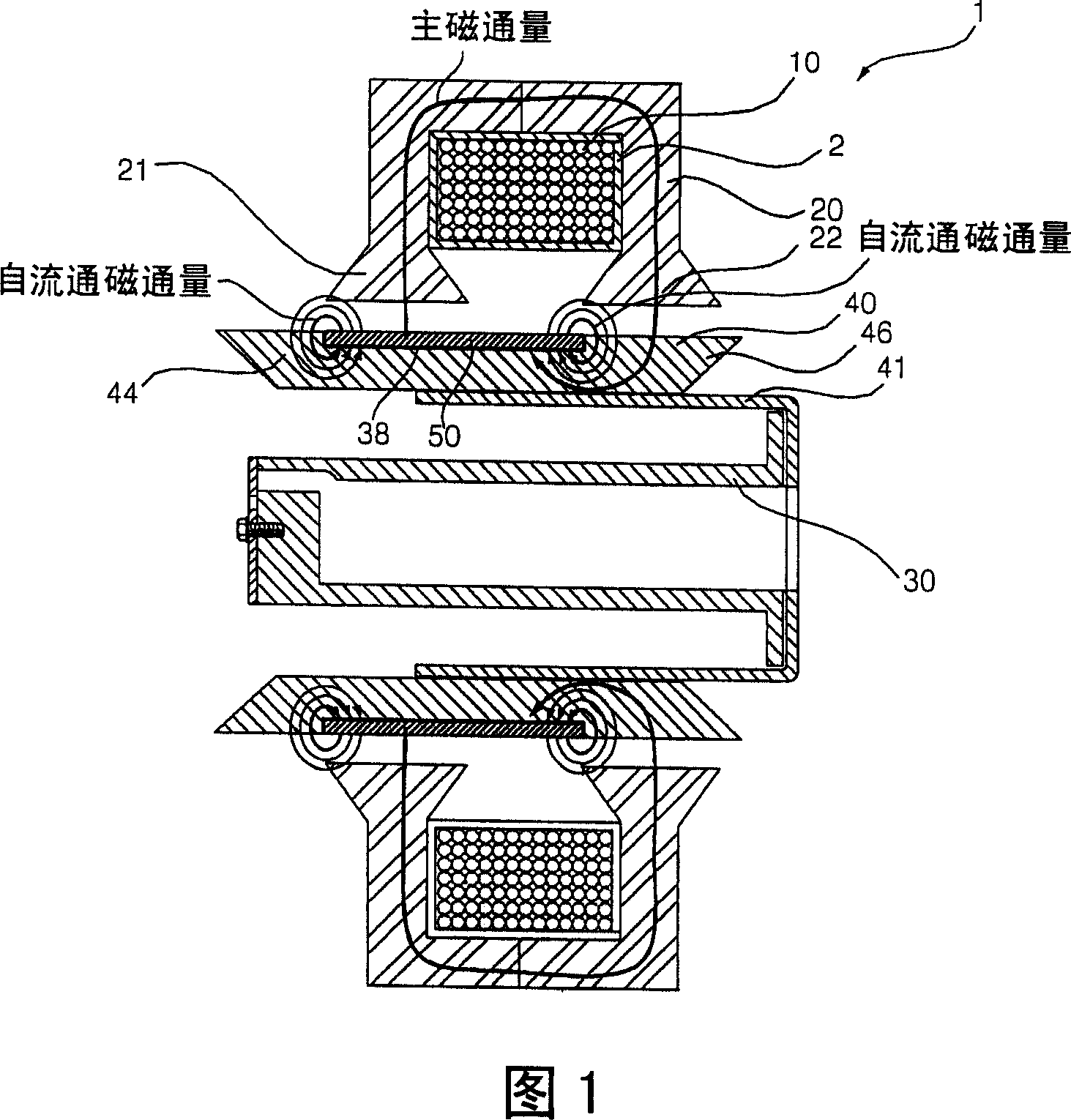

[0037] 1 is a partial longitudinal sectional view of a linear motor according to a first embodiment of the present invention.

[0038] As shown in Figure 1, the linear motor according to the first embodiment of the present invention includes: a bobbin 2, a coil 10, which is wound inside the bobbin 2; an outer core 20, which is mounted on the bobbin 2, an inner core 40 installed to make a linear reciprocating movement of a target moving body 30 such as a piston, and a magnet insertion groove 38 is formed on the outer peripheral surface of the inner core; and a magnet 50, which is inserted and installed in the magnet insertion groove 38 in.

[0039] The bobbin 2 has a cylindrical shape as a whole, and the outer peripheral surface of the bobbin 2 is exposed.

[0040] The coil 10 is wound inside the bobbin 2 .

[0041] When an alternating current is appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com