Optical disc washing procedure and apparatus

An optical disc and process technology, applied in the directions of optical record carriers, optical record carrier manufacturing, refurbishment/cleaning of record carriers, etc., can solve the problems of increasing process cost burden and environmental pollution, saving cleaning time, reducing costs, and improving The effect of productivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

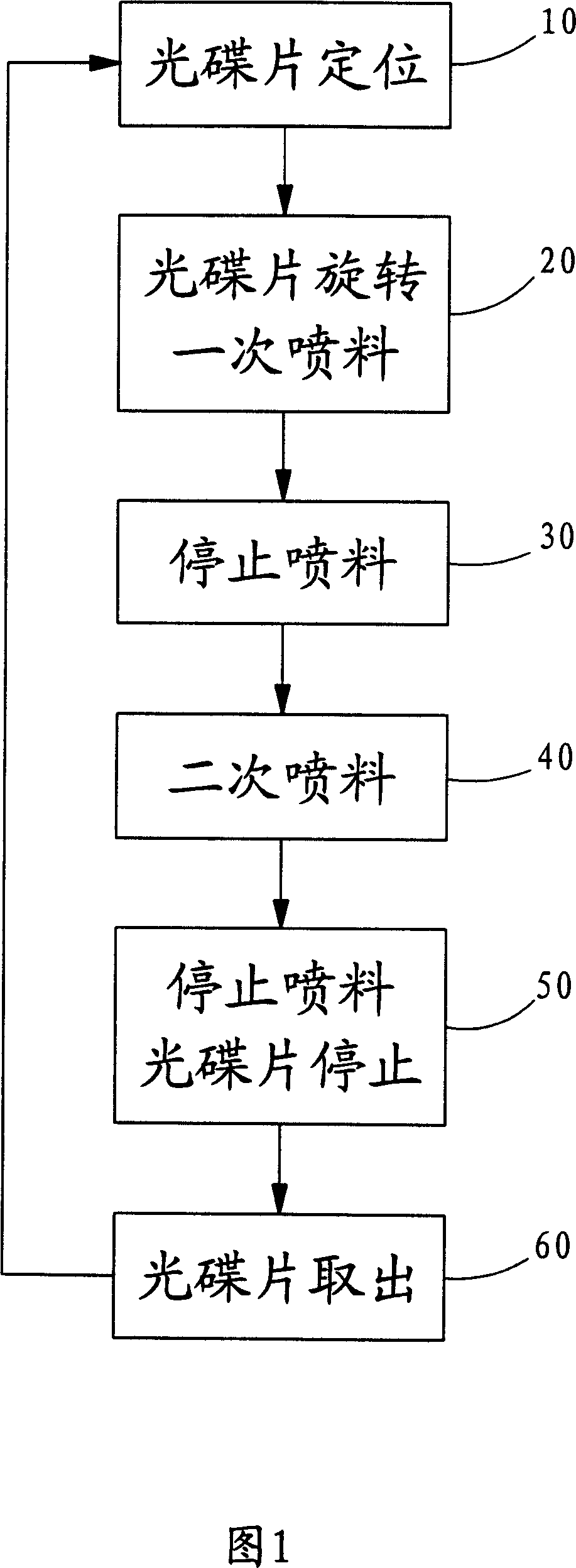

[0032] A kind of CD cleaning process of the present invention, as shown in Figure 1, it comprises the following steps:

[0033] Step 10. Positioning of the optical disc: placing the optical disc on the cleaning disc module for positioning.

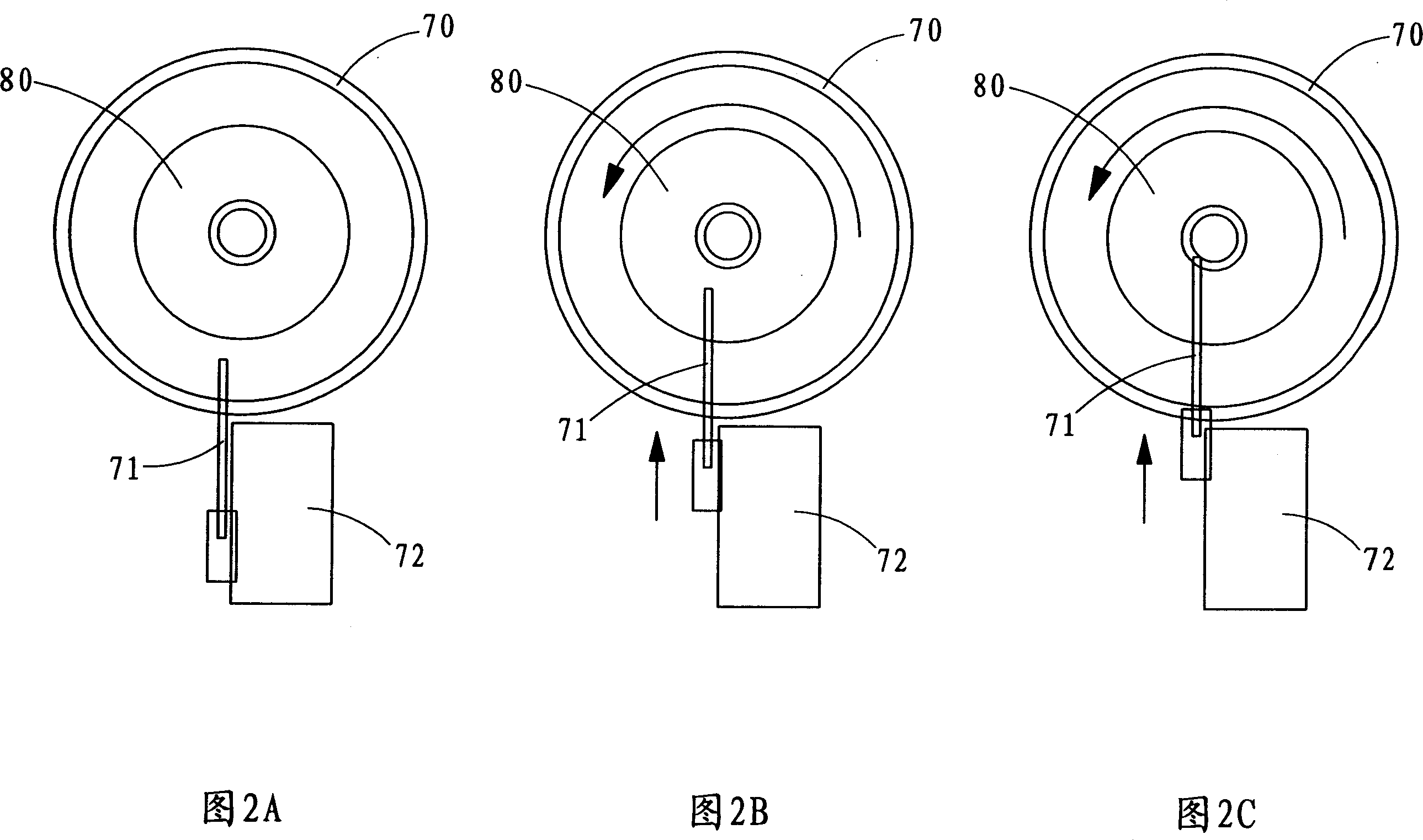

[0034] Step 2 20. Disc rotation and primary spraying: Drive the disc to rotate through the cleaning disc module, and use a nozzle to spray the dye to be used for cleaning the disc, and at the same time make the nozzle gradually move from the outside of the disc to the disc The center of the slice moves.

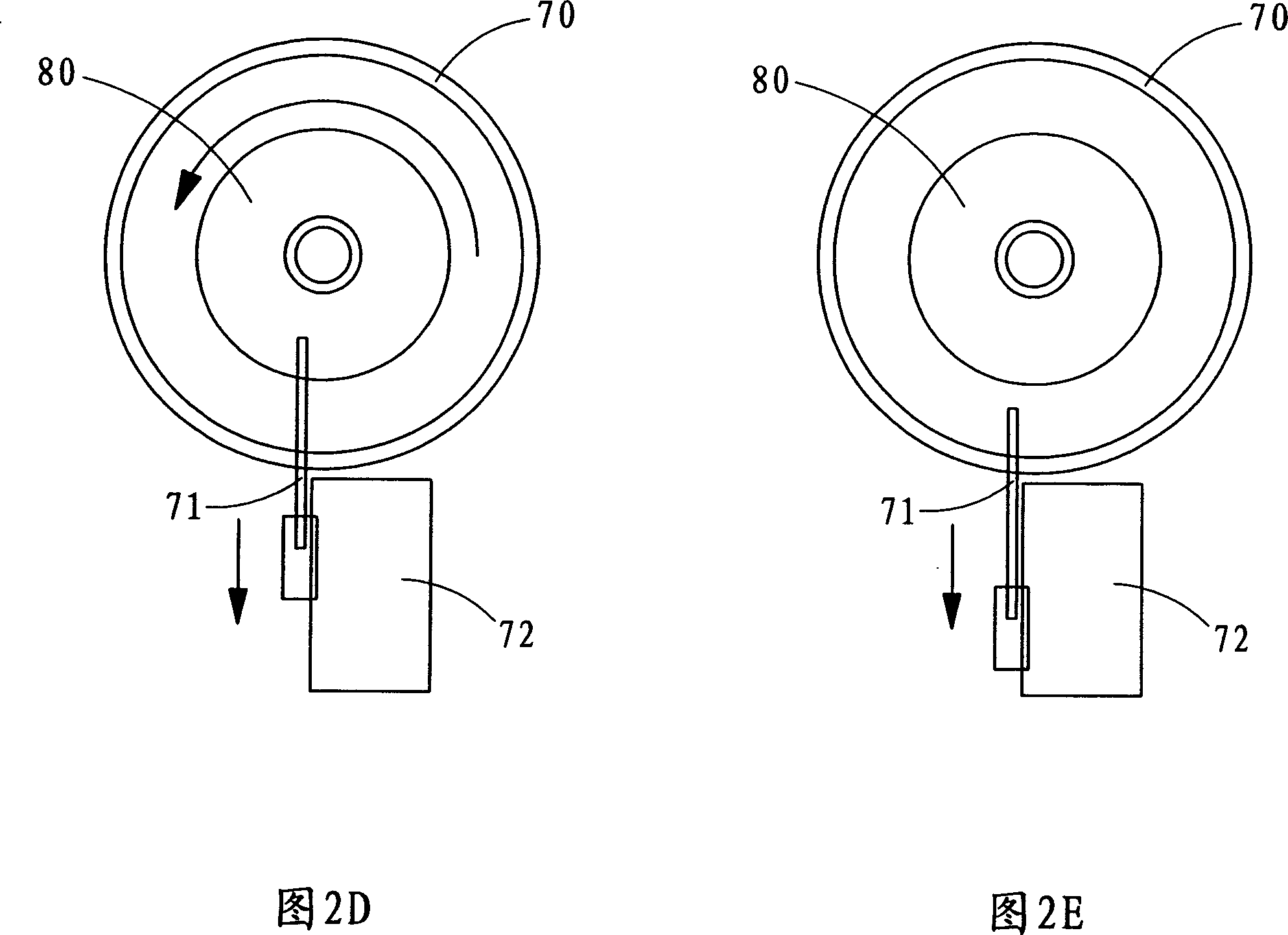

[0035] Step 3 30. Stop spraying: When the nozzle moves to the appropriate position in the center of the optical disc, stop the spraying of the dye, because the dye is gradually sprayed from the outside of the optical disc to the central part, and at the same time use the action of the disc rotation , so that the dye is covered on the disc; moreover, when the disc rotates, centrifugal force will be generated, so when the dye stops sprayin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com