Radiating structure of coverting element of plasma display

A technology of plasma display and conversion element, applied in cooling/ventilation/heating transformation, solid cathode components, etc., can solve the problems of inability to absorb heat evenly, long time required for heat dissipation, poor heat dissipation effect, etc., to avoid disadvantages Influence, prevent components from being exposed, the effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

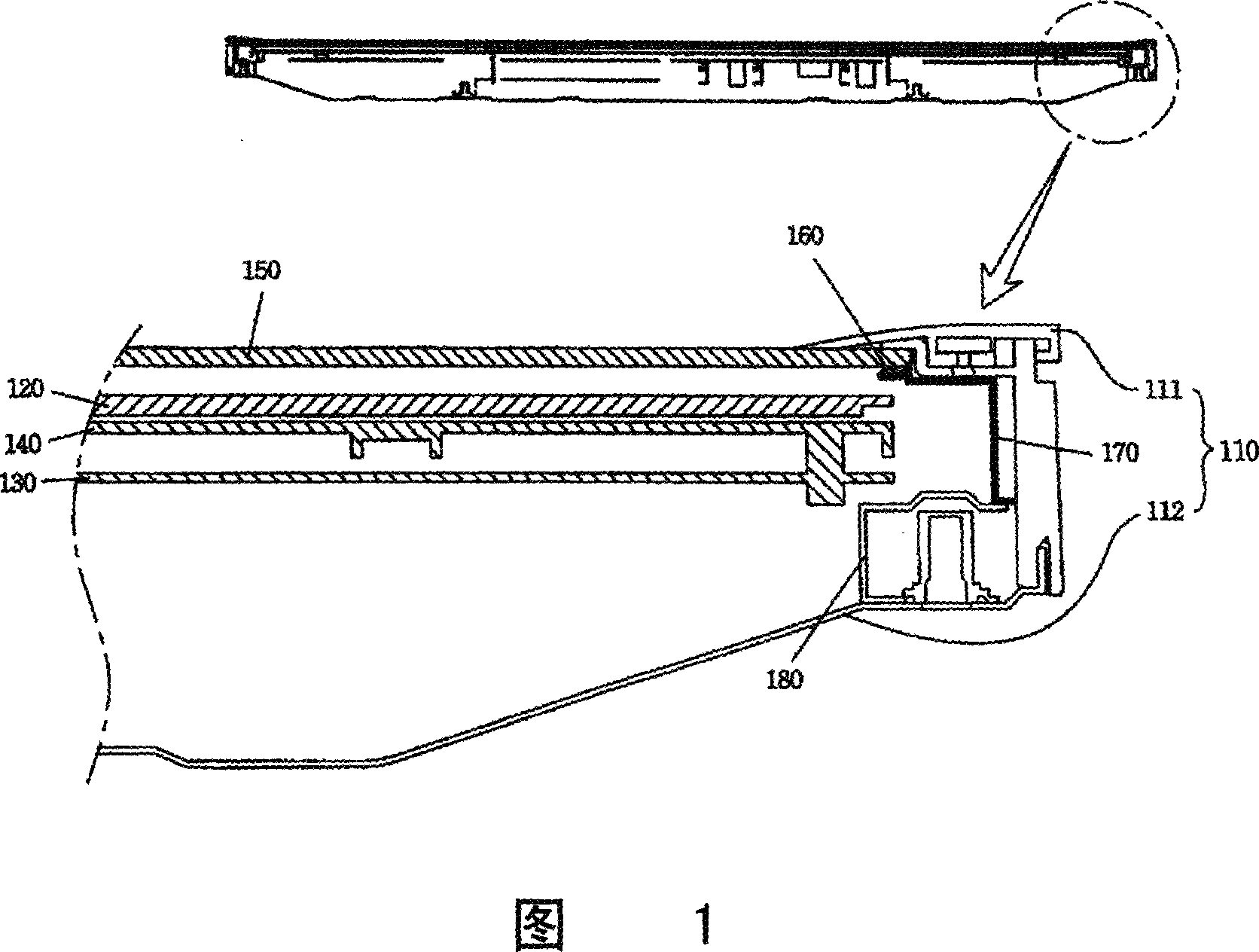

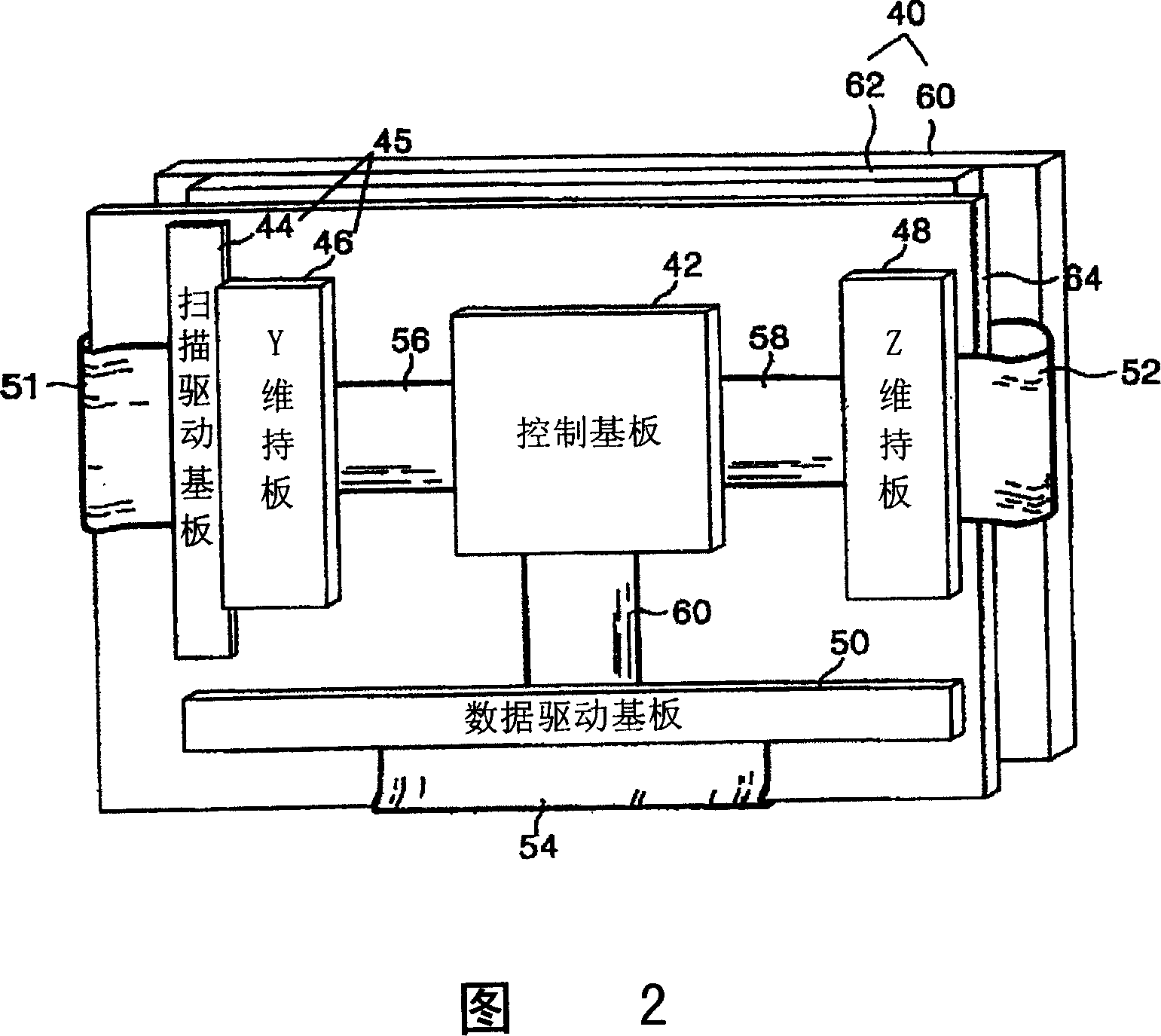

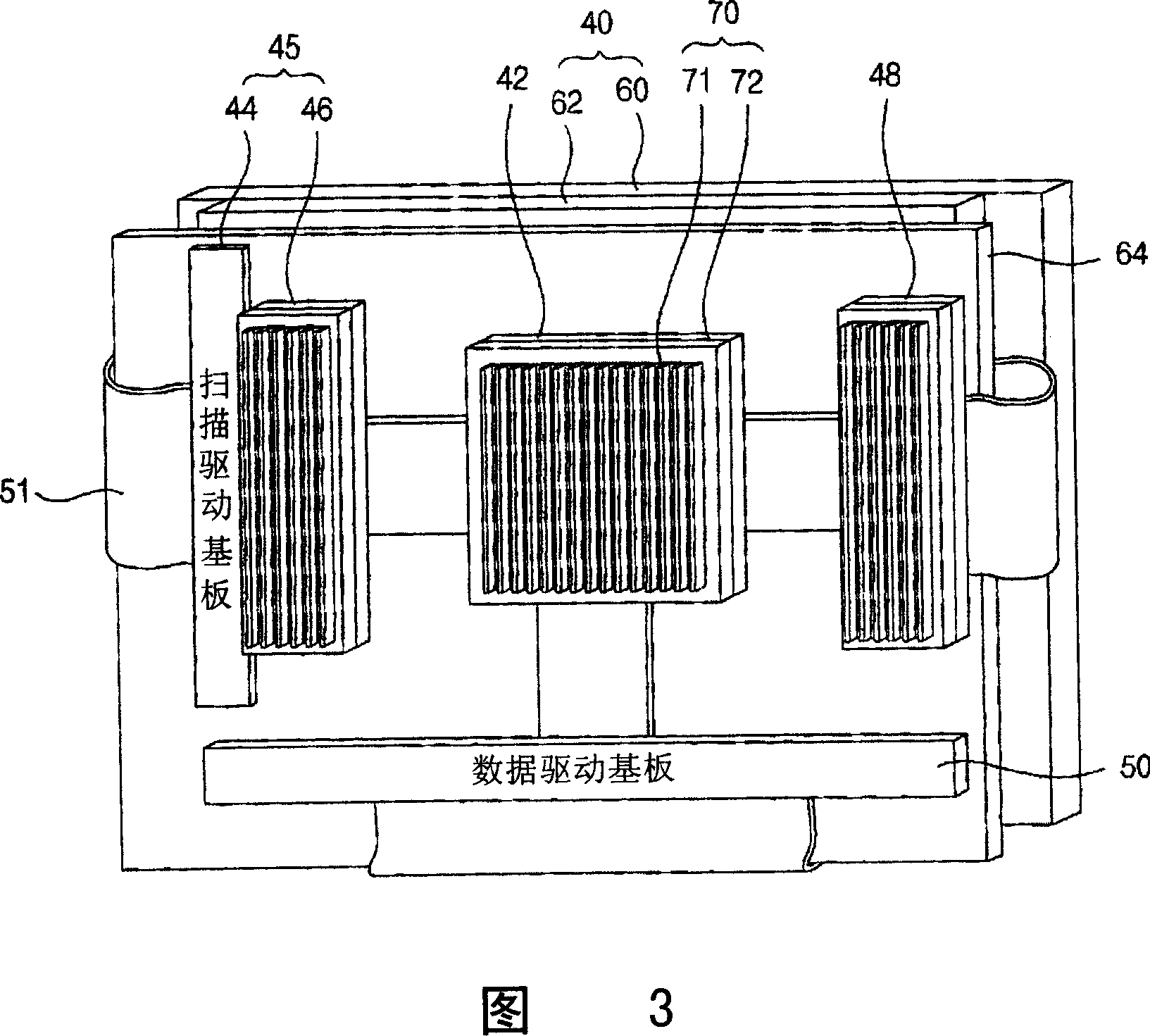

[0045] Hereinafter, specific embodiments of the heat dissipation structure of the conversion element of the plasma display according to the present invention will be described in detail with reference to FIGS. 5 to 8 .

[0046]As shown in FIG. 5 , it is a schematic plan view of the synchronous heat sink installation state of the FET element in the embodiment of the present invention. FIG. 6 is a schematic diagram of a separated state of the cooling fins forming the mounting grooves in the embodiment of the present invention. As shown in Fig. 7a and 7b, the heat conduction situation of the existing heat dissipation structure is compared with the heat conduction situation of the heat dissipation structure of the present invention. FIG. 8 is a schematic diagram of the installation state of the FET element in another embodiment of the present invention.

[0047] First, let's look at the mounting structure of the synchronous heat sink for dissipating heat from the conversion eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com