Exposure equipment

An exposure device and an exposed technology are applied in the direction of exposure devices, optics, instruments, etc. in the photoplate making process, which can solve the problems of increased adjustment time, long exposure time, and prolonged exposure light irradiation time, so as to reduce dirt or damage, Improved exposure accuracy and consistent exposure position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described in detail below with reference to the drawings.

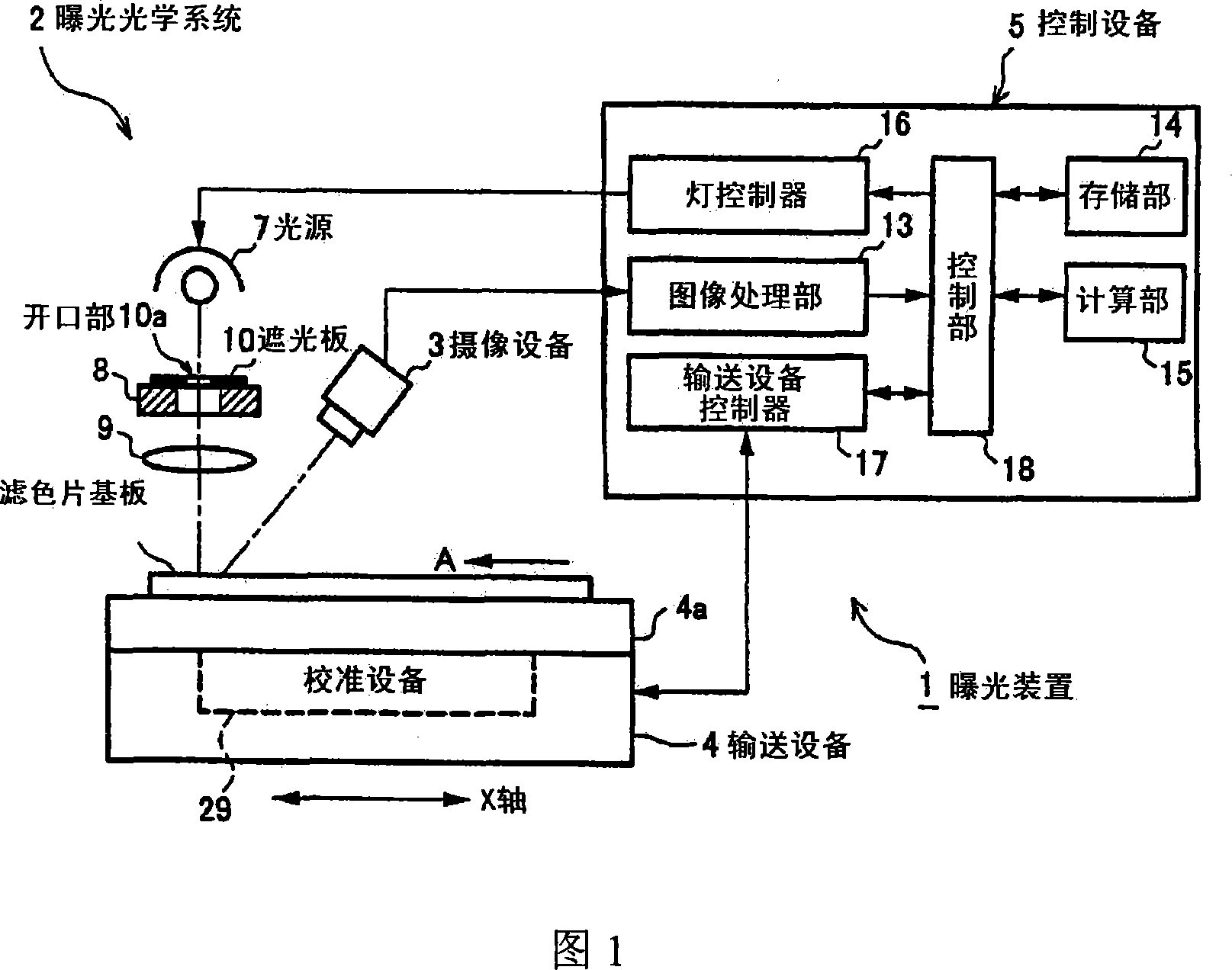

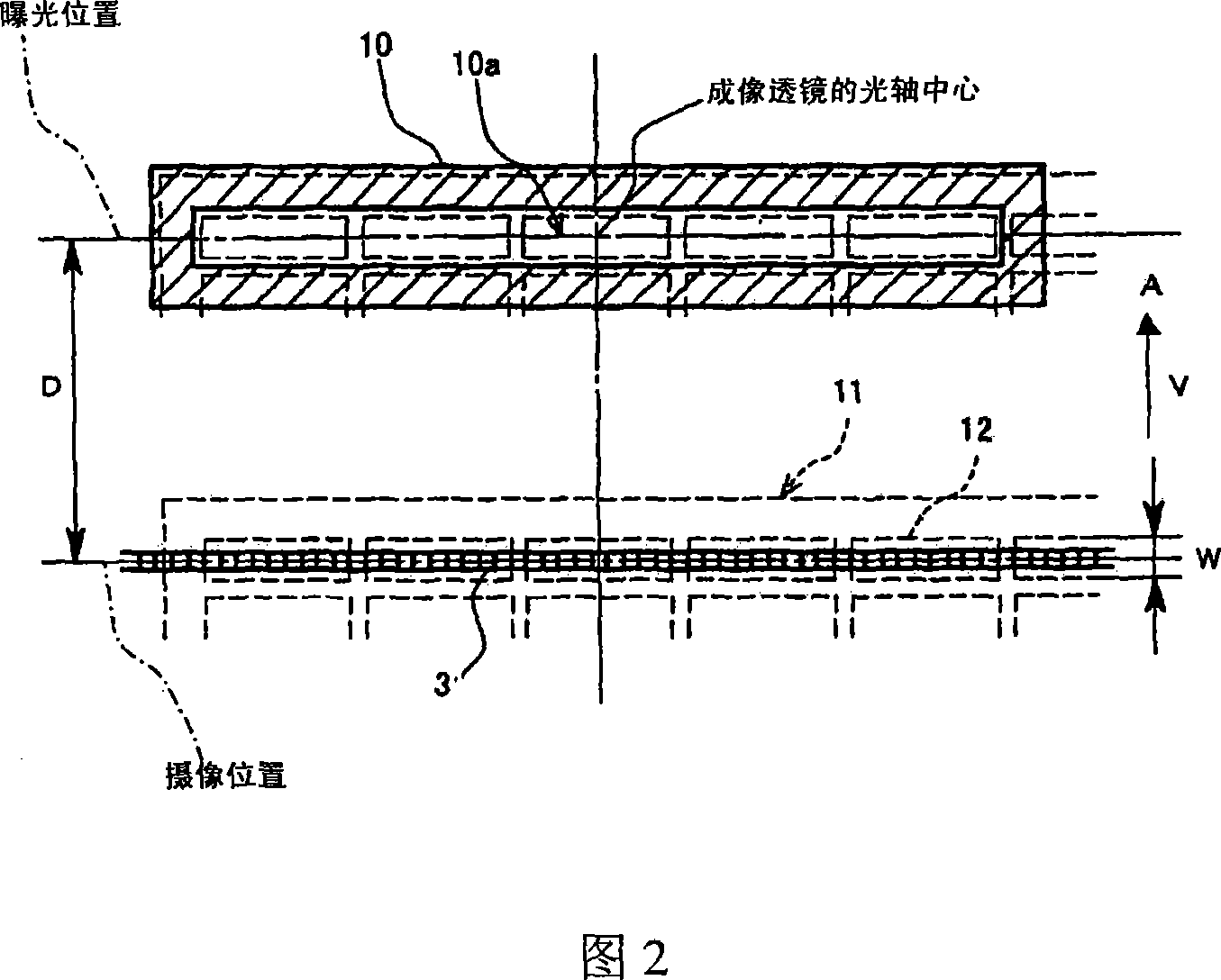

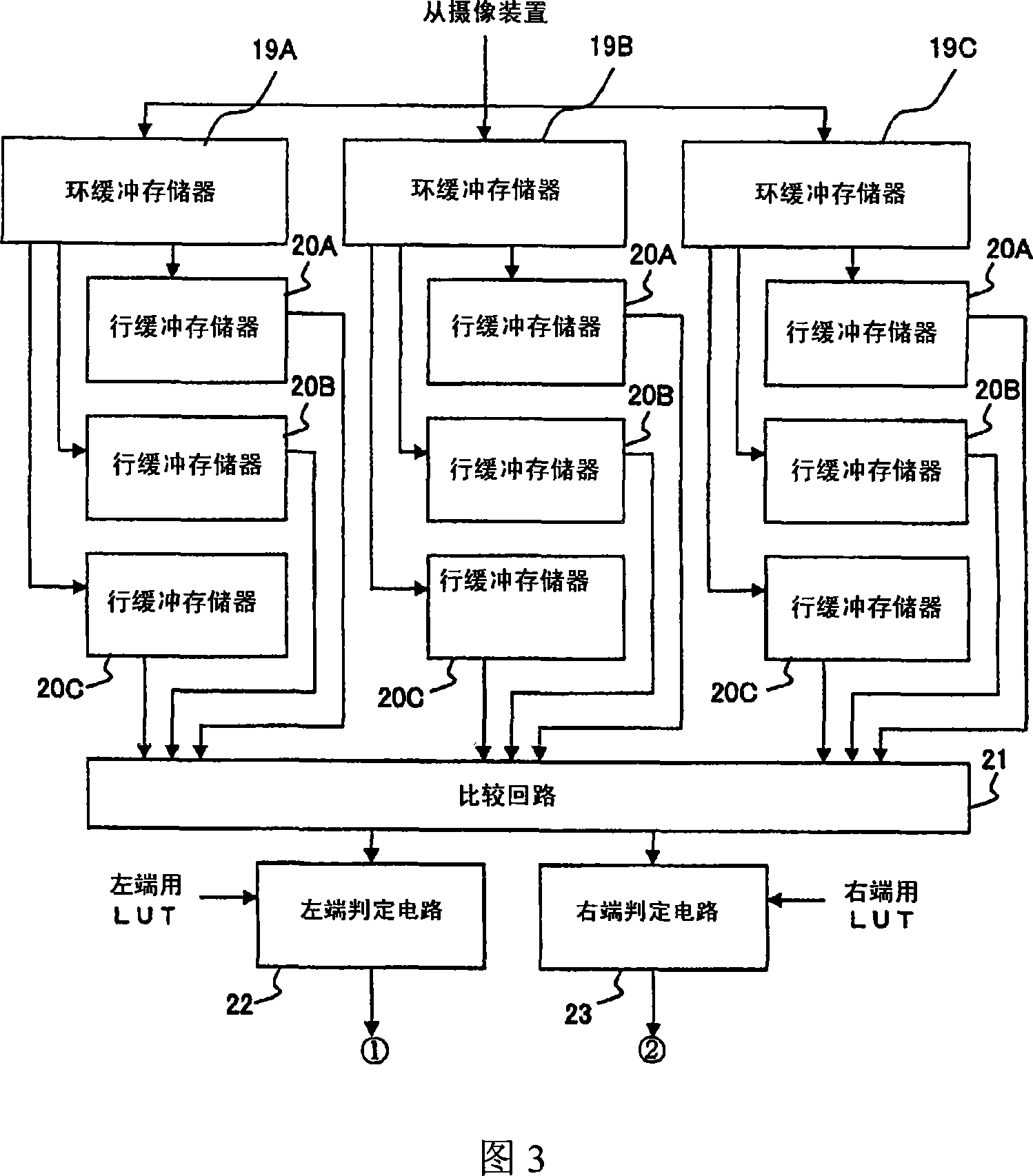

[0038] FIG. 1 is a schematic diagram showing a first embodiment of the exposure apparatus of the present invention. This exposure apparatus 1 irradiates exposure light with an exposure optical system to expose an image of an opening of a light-shielding plate interposed in the path of the exposure optical system on an object to be exposed, and therefore includes an exposure optical system 2 and an imaging device 3 , conveying equipment 4, control equipment 5. In addition, the color filter substrate of a liquid crystal display unit is demonstrated as an example of an object to be exposed.

[0039] The exposure optical system 2 irradiates exposure light onto the color filter substrate 6 coated with a photosensitive agent to expose a predetermined color filter pattern, and includes a light source 7 , a light shield stage 8 and an imaging lens 9 .

[0040] The light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com