Antifreezing composition

A technology of composition and antifreeze, which is applied in the field of antifreeze composition, and can solve problems such as low solubility, reduced performance of corrosion inhibitors, and reduced anti-corrosion effect of solder

Inactive Publication Date: 2007-06-20

HYUNDAI MOTOR CO LTD

View PDF6 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these compositions also have similar disadvantages

Corrosion inhibitors used therein tend to have low solubility and must be heat treated to make them soluble in antifreeze compositions

However, due to the increased amount of carboxylic acid-based additives, the corrosion resistance of the solder decreases at high temperature

Corrosion inhibitor performance is greatly reduced when used at low concentrations or in the presence of water containing corrosive ions or hard water components

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4

[0050] As shown in Table 1 below, all components of the antifreeze composition were mixed with glycol and water in predetermined ratios, which were heated to about 50°C to form a homogeneous liquid. The compositions thus produced were tested according to the test method described hereinafter and the results are shown in Tables 2-5.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to an improved antifreeze composition for use in engine cooling systems. The composition of the invention has sustained corrosion inhibiting properties even at relatively low concentrations and when used with hard water. The composition comprises an antifreeze agent, an organic acid, a poly(organic acid), dimercapto thiadiazole, a hard water stabilizer, a phosphate salt, a triazole or thiazole and alkali metal hydroxide.

Description

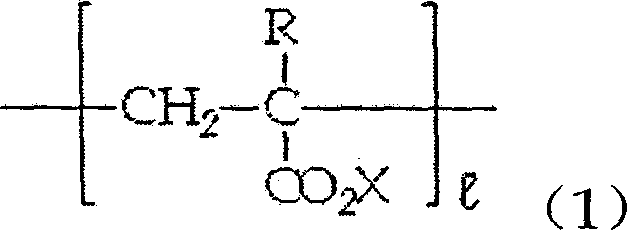

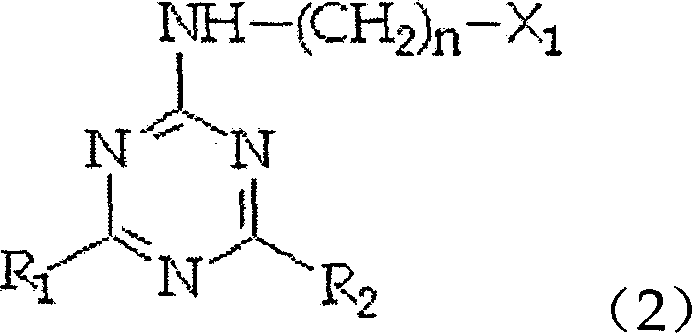

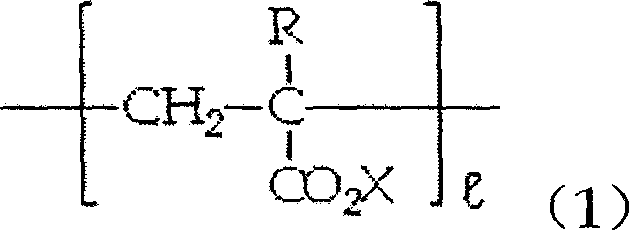

[0001] Cross References to Related Applications [0002] This application is based on and claims priority from Korean Patent Application No. 10-2005-0121759 filed on December 12, 2005, the entire disclosure of which is hereby incorporated by reference. technical field [0003] The present invention mainly relates to an antifreeze composition. More specifically, the present invention relates to improved antifreeze compositions having durable anti-corrosion properties that can be used in engine cooling systems. Background technique [0004] The function of the antifreeze is to remove heat as it circulates through the engine and release this heat as the antifreeze passes through the radiator. Typically, antifreeze compositions are formulated using alkylene glycols, such as ethylene glycol, propylene glycol, or derivatives thereof, as antifreeze agents. When used in the refrigeration system of a vehicle or aircraft, the antifreeze is diluted with water to ensure good heat diss...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K5/20

CPCC02F1/68C23F14/02C09K5/20C23F11/10C09K5/10

Inventor 柳成春河宁柱赵昌烈崔东烈

Owner HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com