Method for electric rolling-gate controller

A control method and control machine technology, applied in the direction of electrical program control, program control, digital control, etc., can solve the problems of inconvenient change of engineering personnel, loss of industrial competitiveness, and inability to effectively reduce manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

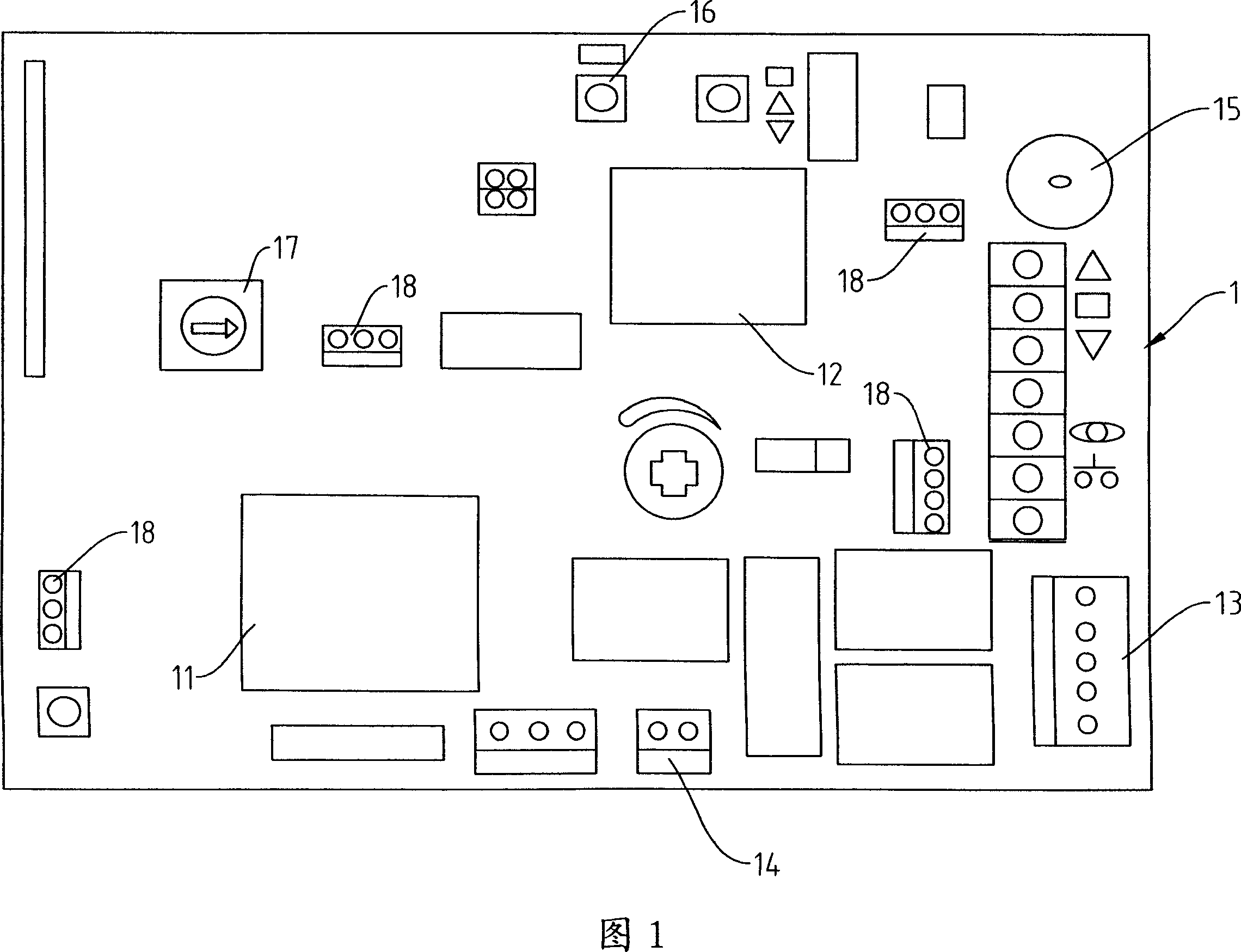

[0020] Please refer to Fig. 1, the control method of the electric rolling door control machine of the present invention, the control machine is mainly used as a motor for controlling the operation of the rolling door, and the main board 1 includes:

[0021] A microprocessor 11 (Micro Processor Unit) is used as a control through burning programs.

[0022] A memory 12 is a kind of erasable memory (EEPROM), which is mainly used to store the data of the upward travel of the rolling door.

[0023] A motor connection seat 13 is used as a connecting component between the motor and the main board 1, and the motor is controlled by the signal of the microprocessor 11, wherein the motor is a clutch type DC motor, which can use an electronically controlled mechanical clutch and a disconnection When the power is on, use the wrench to control the clutch gear, and at the same time, it has the function of manually opening and closing the rolling door, and the motor further includes a Hall IC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com