Device and methods for braking in a motor vehicle

A braking device and control device technology, applied in the direction of brakes, noise/vibration control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

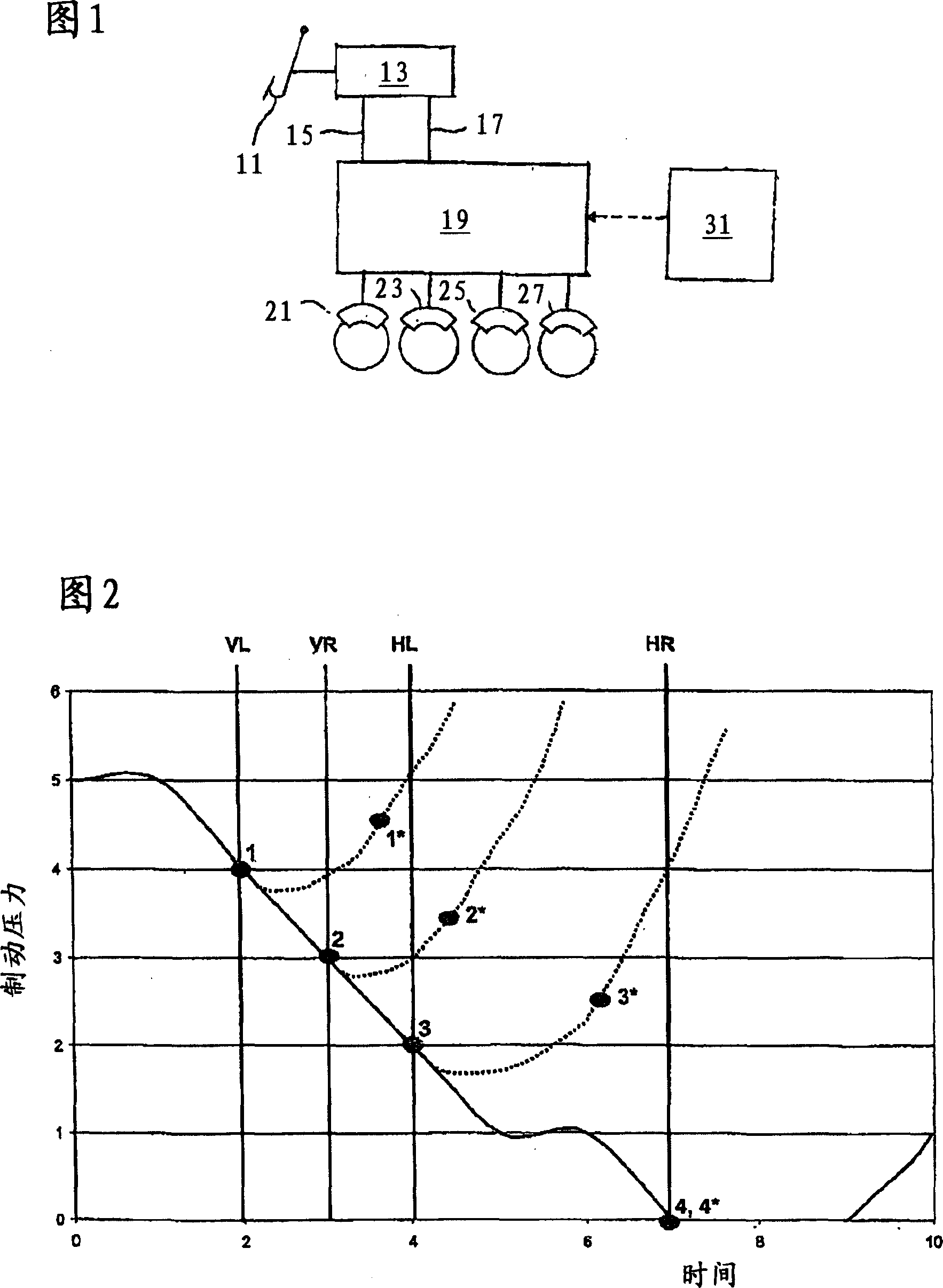

[0022] FIG. 1 shows a braking system for a vehicle (not shown) with friction brakes for each wheel. The brake device is designed in a known manner as a hydraulic or electrohydraulic friction brake and has a brake master cylinder 13 which can be mechanically actuated via a brake actuating device in the form of a brake pedal 11 , the brake master cylinder is hydraulically connected to a hydraulic assembly 19 via a first output line 15 of a first brake circuit and a second output line 17 of a second brake circuit. The four wheel brakes 21 , 23 , 25 , 27 of the vehicle are connected to the hydraulic unit 19 so that the brake pressures in the wheel brakes 21 , 23 , 25 , 27 can each be adjusted via the hydraulic unit 19 .

[0023] The detailed structure of the hydraulic unit 19 is known to the skilled person from the usual hydraulic or electrohydraulic brake systems in today's vehicles, which have driving stability control devices (eg ESP), anti-lock brake control devices ( ABS) or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com