Valve for use in a fuel line of a motor vehicle

A technology for fuel delivery and motor vehicles, applied to fuel injection pumps, machines/engines, fuel injection devices, etc., to achieve the effects of simple structure, small valve body vibration characteristics, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

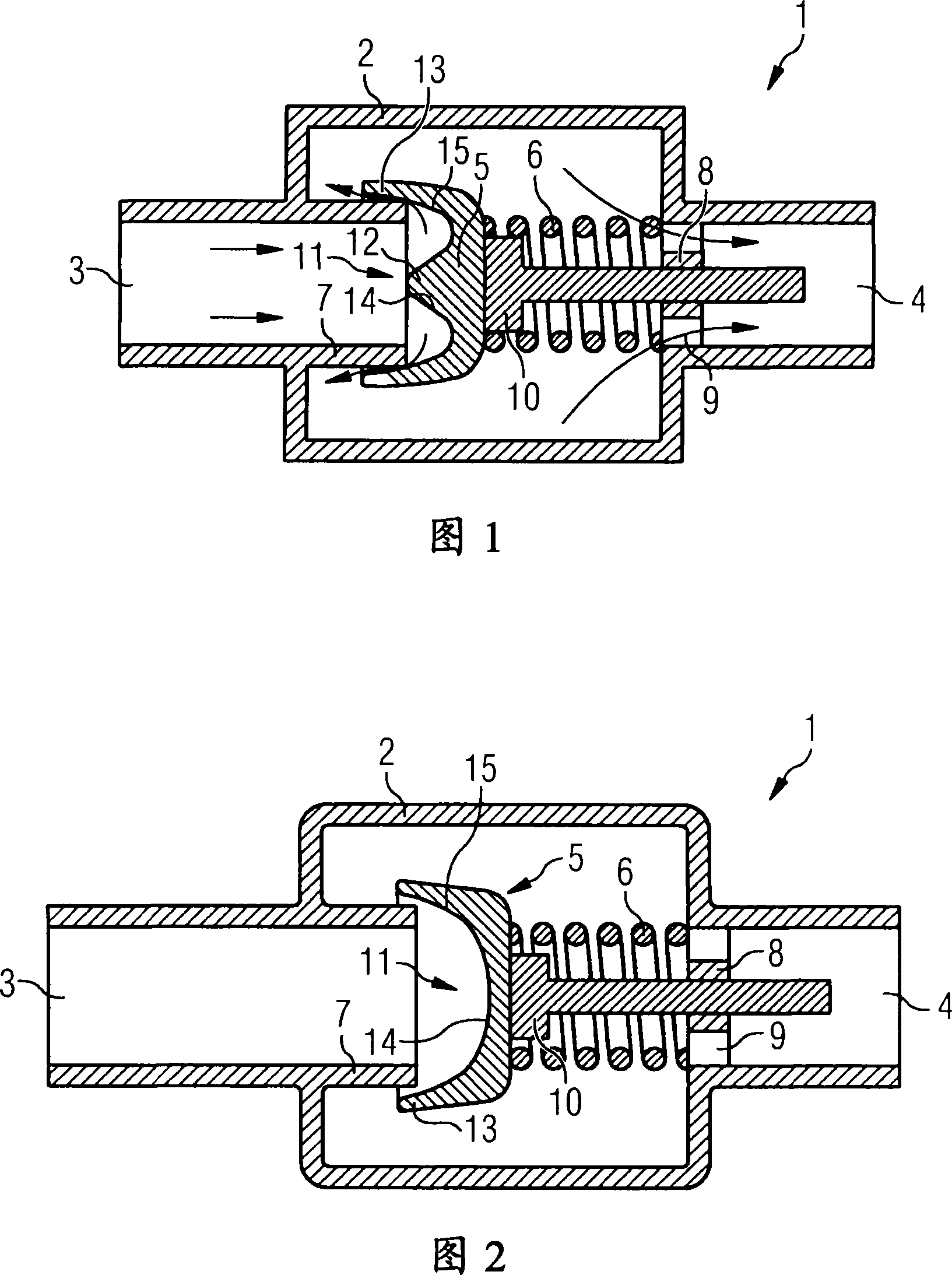

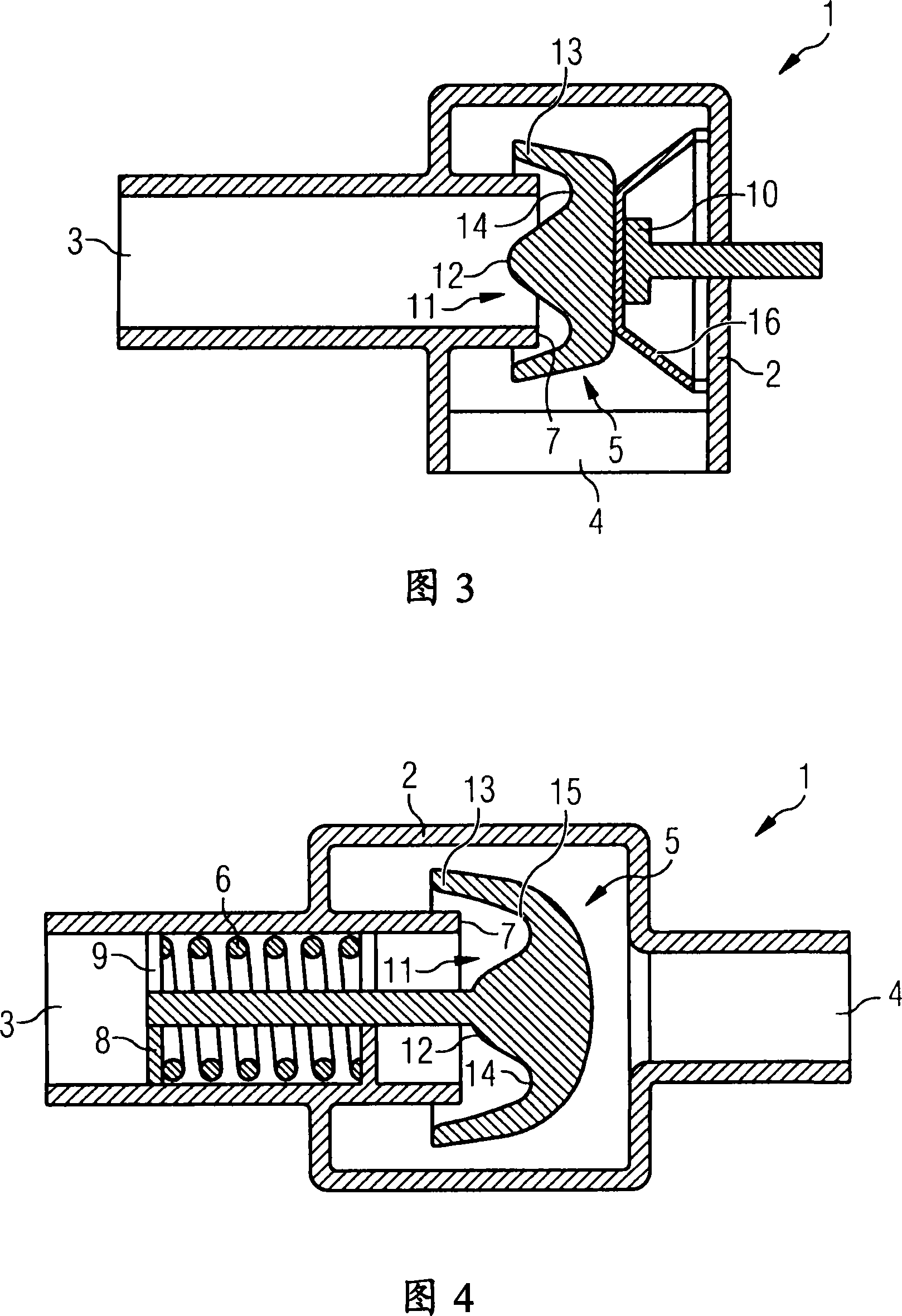

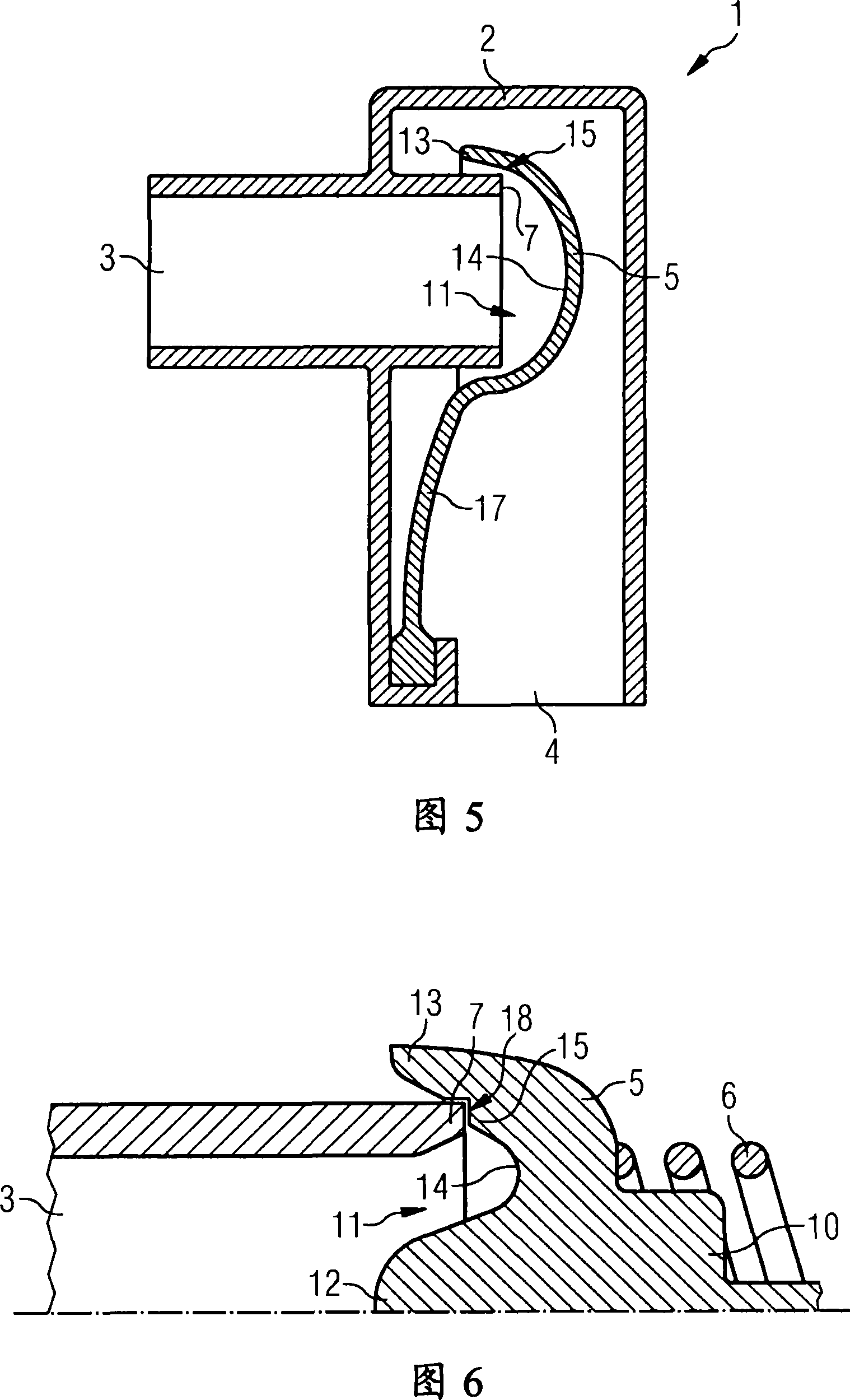

[0024] The valve shown in Figure 1 is installed in the fuel line as a check valve. The valve 1 has a housing 2 which has an inlet 3 and an outlet 4 on its two side faces, wherein the inlet 3 is inserted into the housing 2 . The inlet 3 and outlet 4 can be connected to pipe ends (not shown) of fuel pipes. The inlet 3 is closed by a valve body 5 which is pressed against the inlet 3 by a helical spring 6 against a sealing seat 7 . Furthermore, the valve body 5 has a receptacle 10 for the helical spring 6 on the side facing away from the sealing seat. The helical spring 6 is supported with its end facing away from the valve body 5 on a support body 8 which has perforations 9 for the passage of fuel.

[0025] On the side facing the sealing seat 7 , the valve body 5 has a contour 11 formed by a centrally arranged central projection 12 and a radially outer peripheral projection 13 . The two projections 12 , 13 are connected to one another by means of the concavely formed surface 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com