Apparatus for detecting joints in rubber sheets

A technology of equipment and plates, applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects, etc., can solve problems such as poor capabilities and positioning errors, and achieve high precision and effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

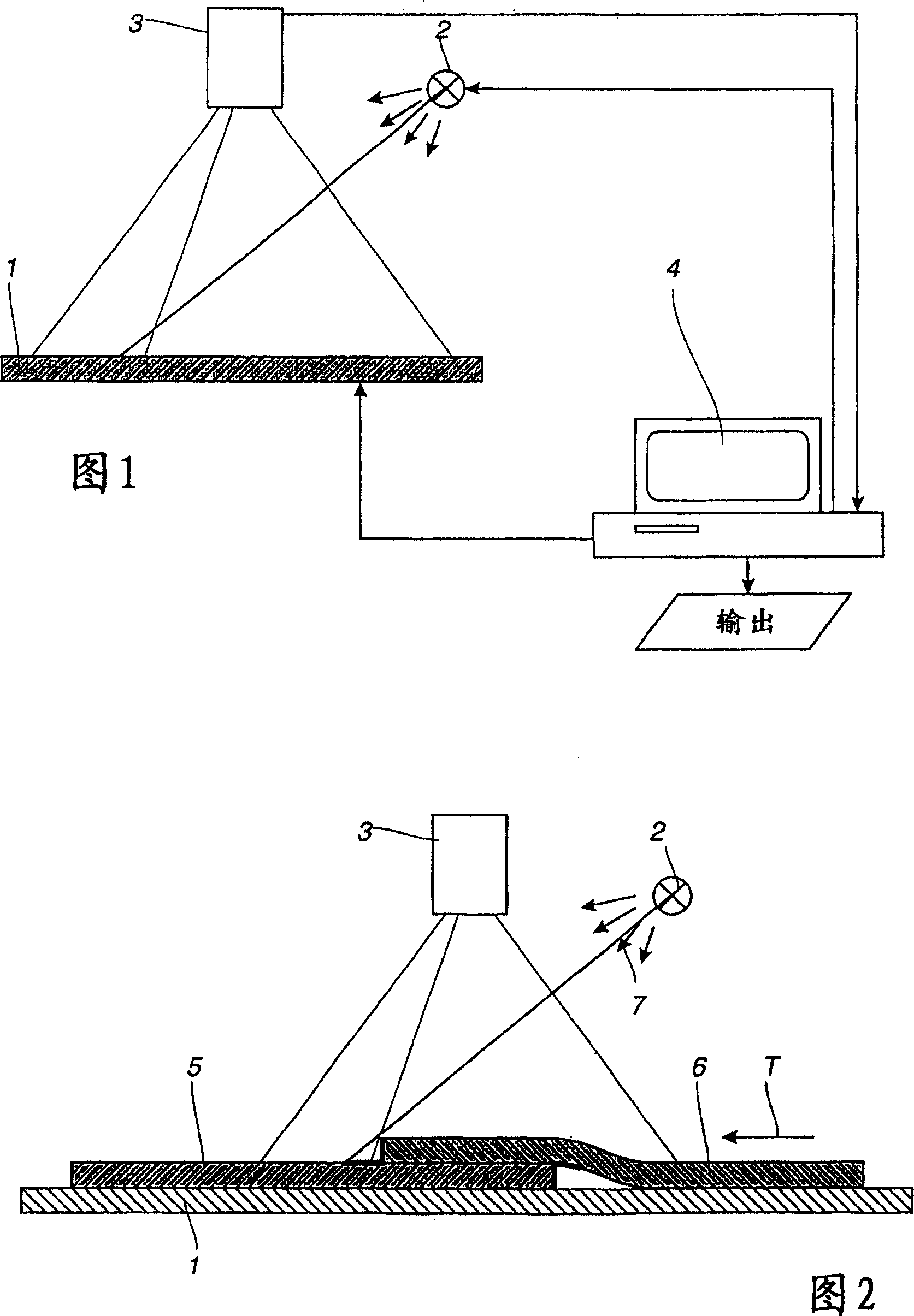

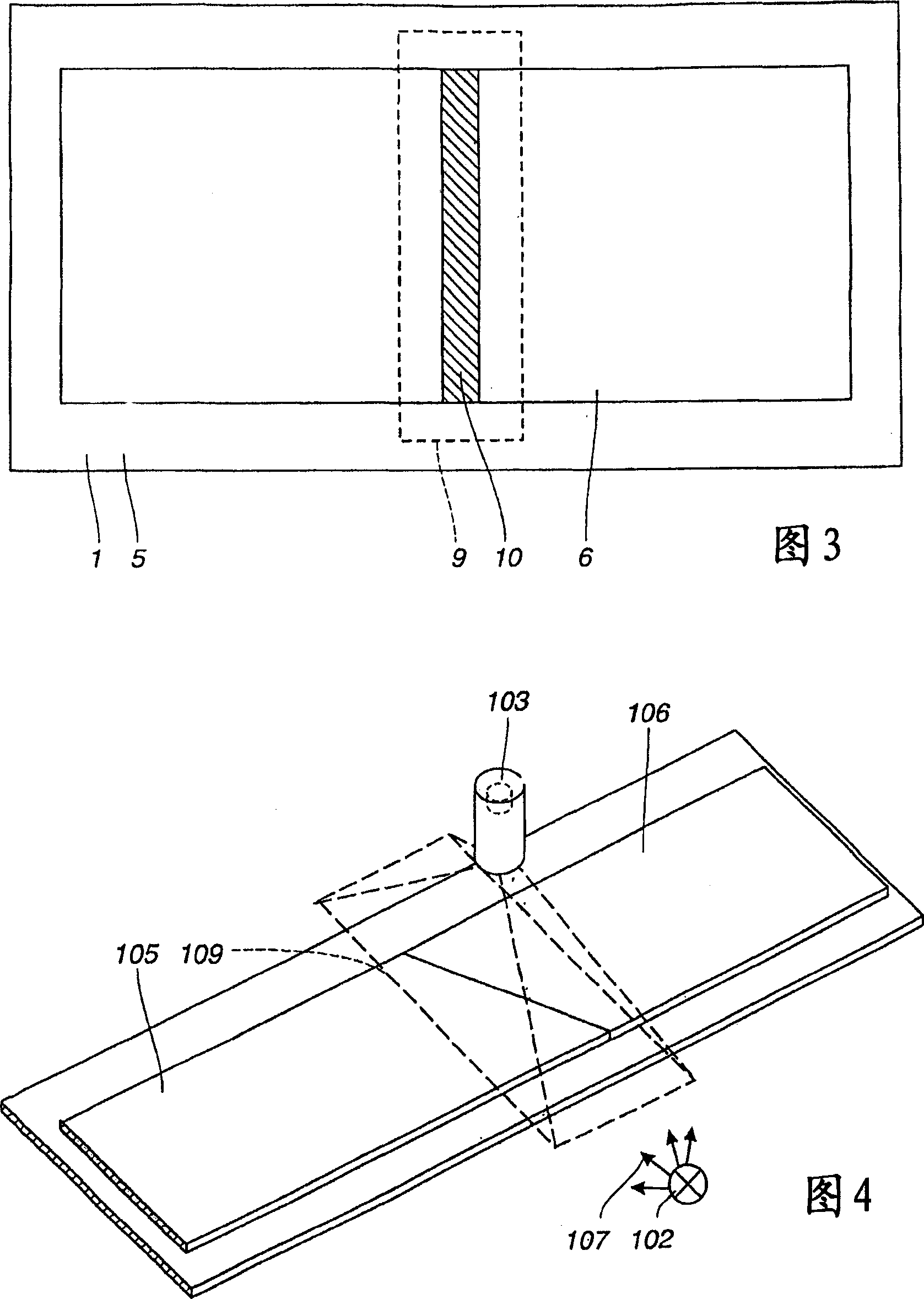

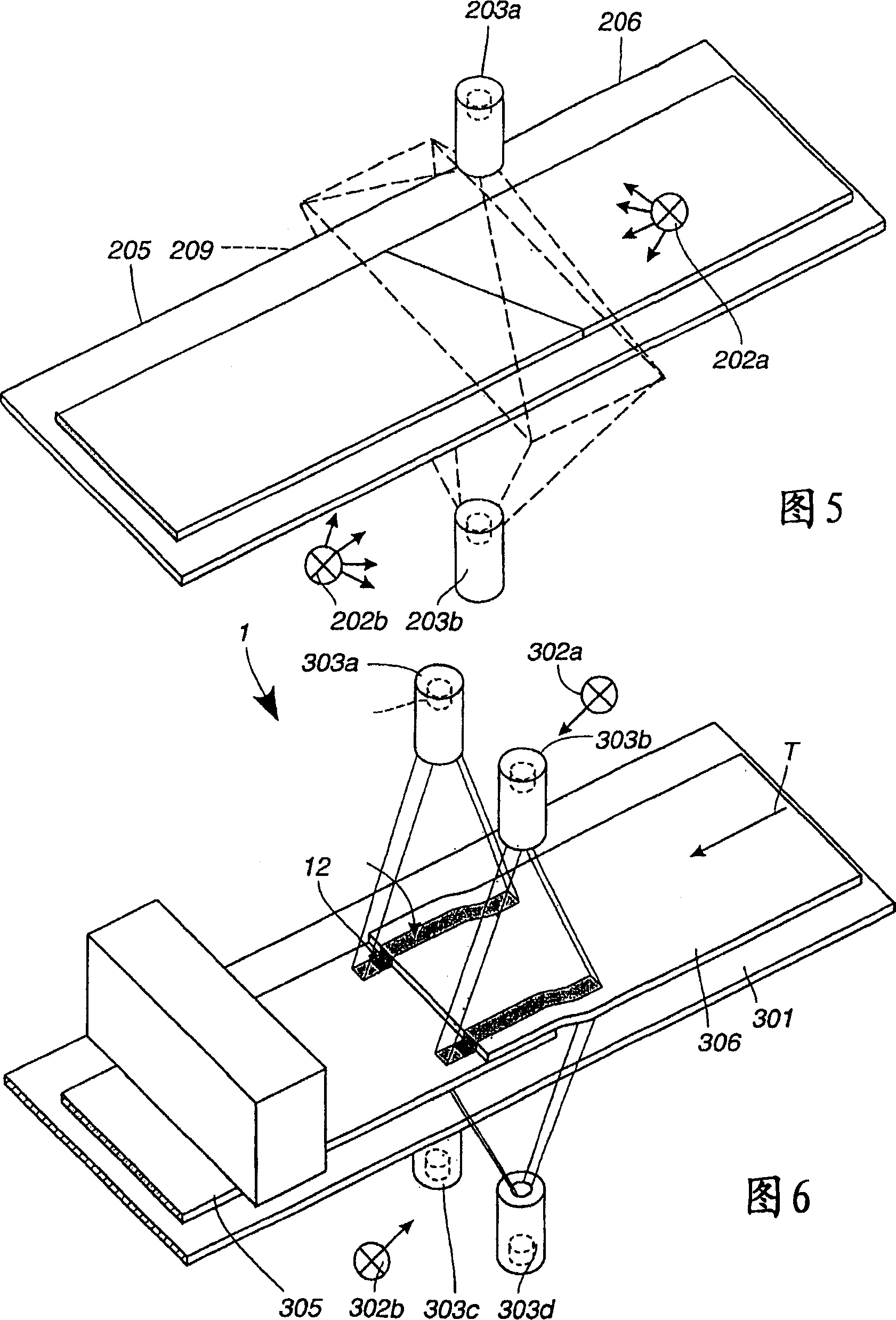

[0055] Referring first to Figures 1 to 3, according to the invention, for detecting geometric properties (for example, for dimensional inspection) and / or for detecting seams in sheets 5, 6 of rubber or other flexible material forming a belt or other strip-like product or a device for defects in a seam, comprising a device 1 intended to correspond to at least one source of electromagnetic radiation 2 directed at the seam or seam (obtained, for example, by means of welding), and to detect At least one sensor 3 of radiation reflected or refracted by a seam or seam is placed correspondingly to said seam or seam.

[0056] It should be observed that although means 1 for placing seams or seams corresponding to at least one electromagnetic radiation source 2 and at least one detection sensor 3 are provided and described in the apparatus described here, these means 1 may not be integrated in the In the detection device according to the invention, and may then be provided on another aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com