ABS system based on combined mechanical hydraulic and motor feedback

An anti-lock braking and combined action technology, applied in the direction of brakes, etc., can solve the problems of high cost, poor control effect, complex system, etc., and achieve the effect of convenient control, fast response speed and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

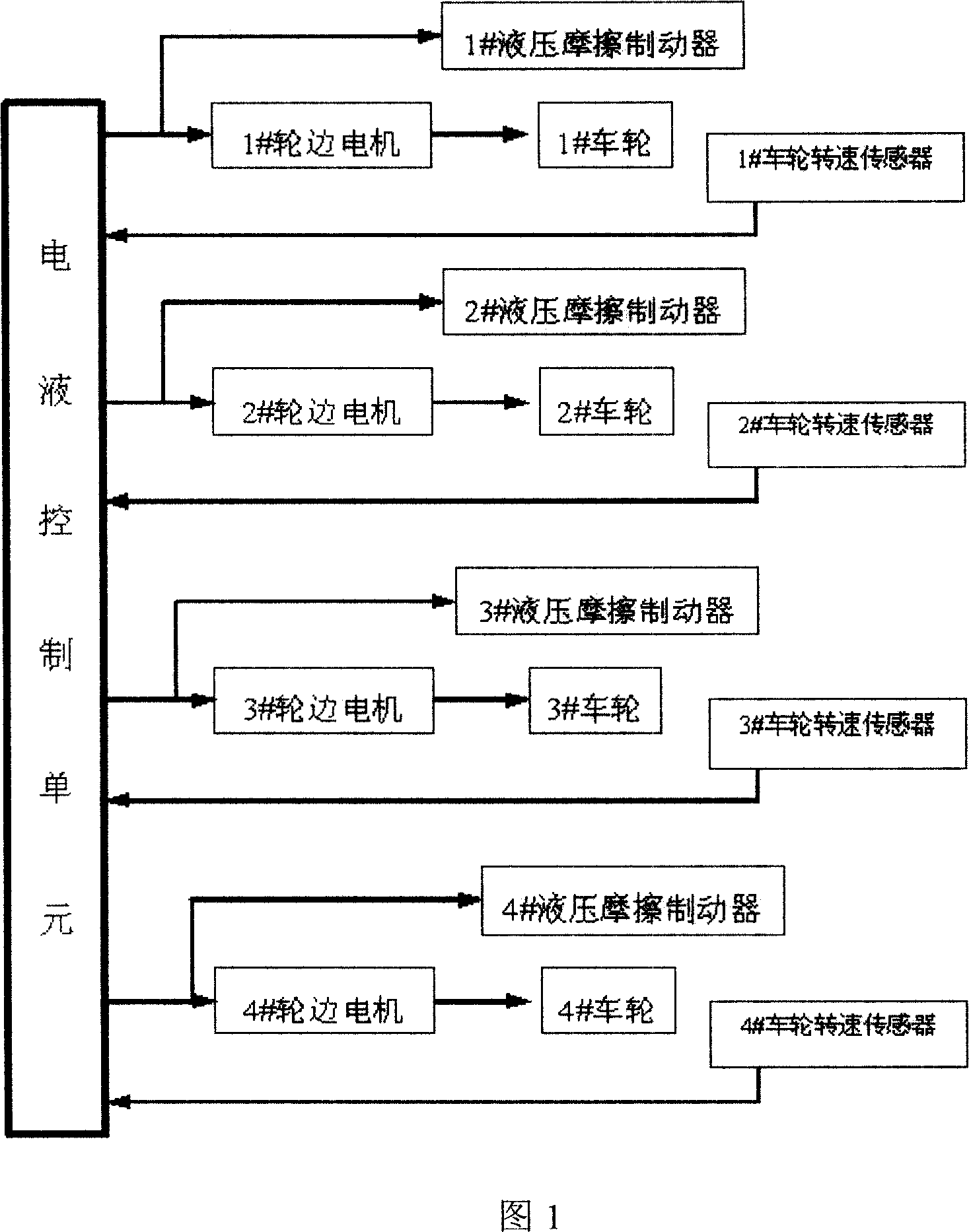

[0008] As shown in Figure 1, the composite anti-lock control system of the four-wheel electric-wheel-drive electric vehicle of the present invention consists of an electro-hydraulic control unit, four hydraulic friction brakes, four wheel motors, four wheel speed sensors, and The motor drive power supply is composed.

[0009] When the driver implements an emergency braking operation, first, the electro-hydraulic control unit controls the hydraulic friction brake and the motor feedback braking to generate the maximum braking torque to ensure that the braking action takes effect in time. Calculate the angular deceleration of the wheels and the identified vehicle speed signal according to the rotational speed signal obtained by the wheel speed sensor. According to the anti-lock brake control logic, the target braking torque required by the wheel is given, and the target braking torque is calculated. The command is distributed to the hydraulic brake system and the motor at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com