X-ray detecting method for printed circuit board defect

A printed circuit board, light detection technology, used in electronic circuit testing, non-contact circuit testing, material analysis using radiation, etc. and other problems to achieve high test coverage, improve first pass rate, and shorten preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

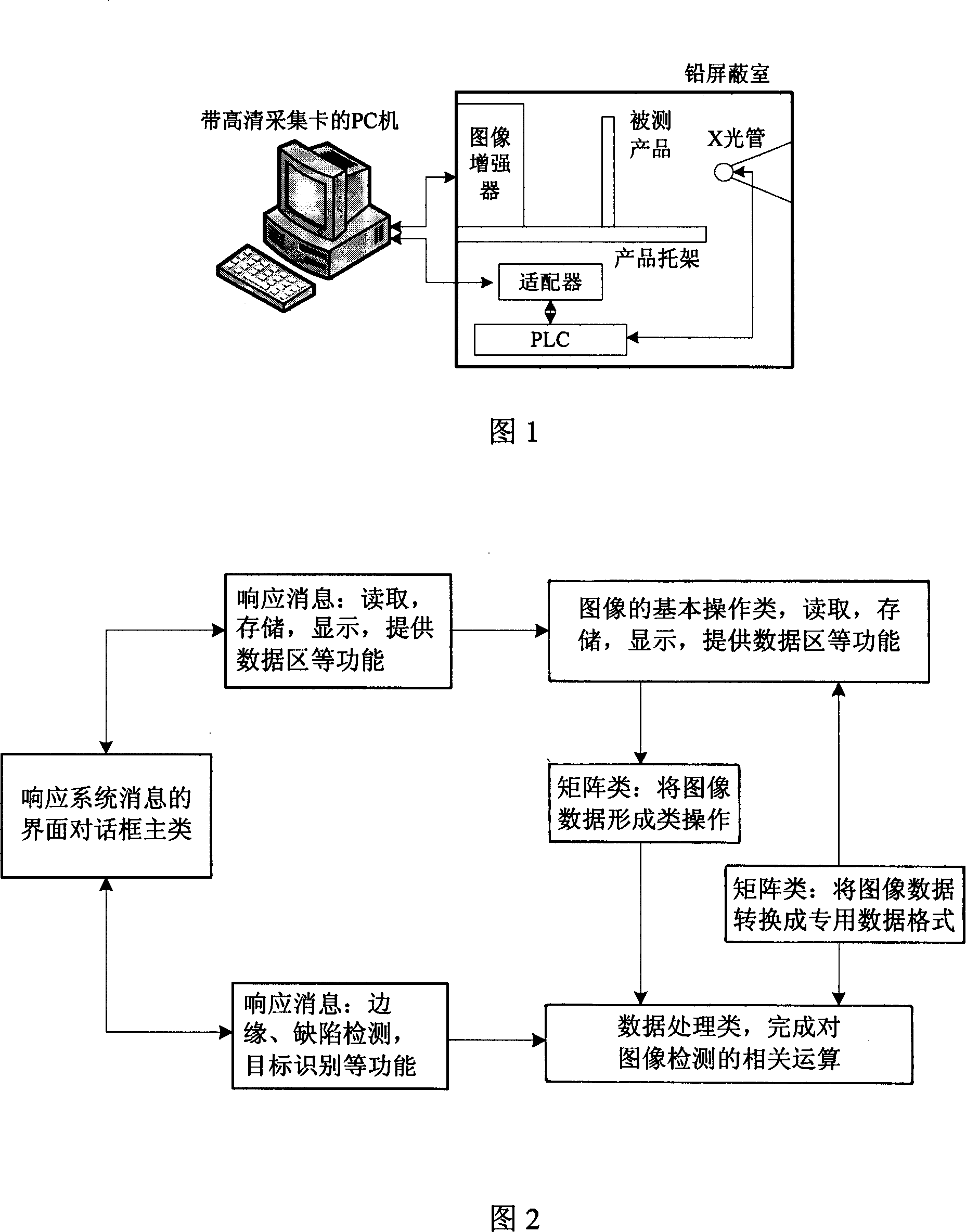

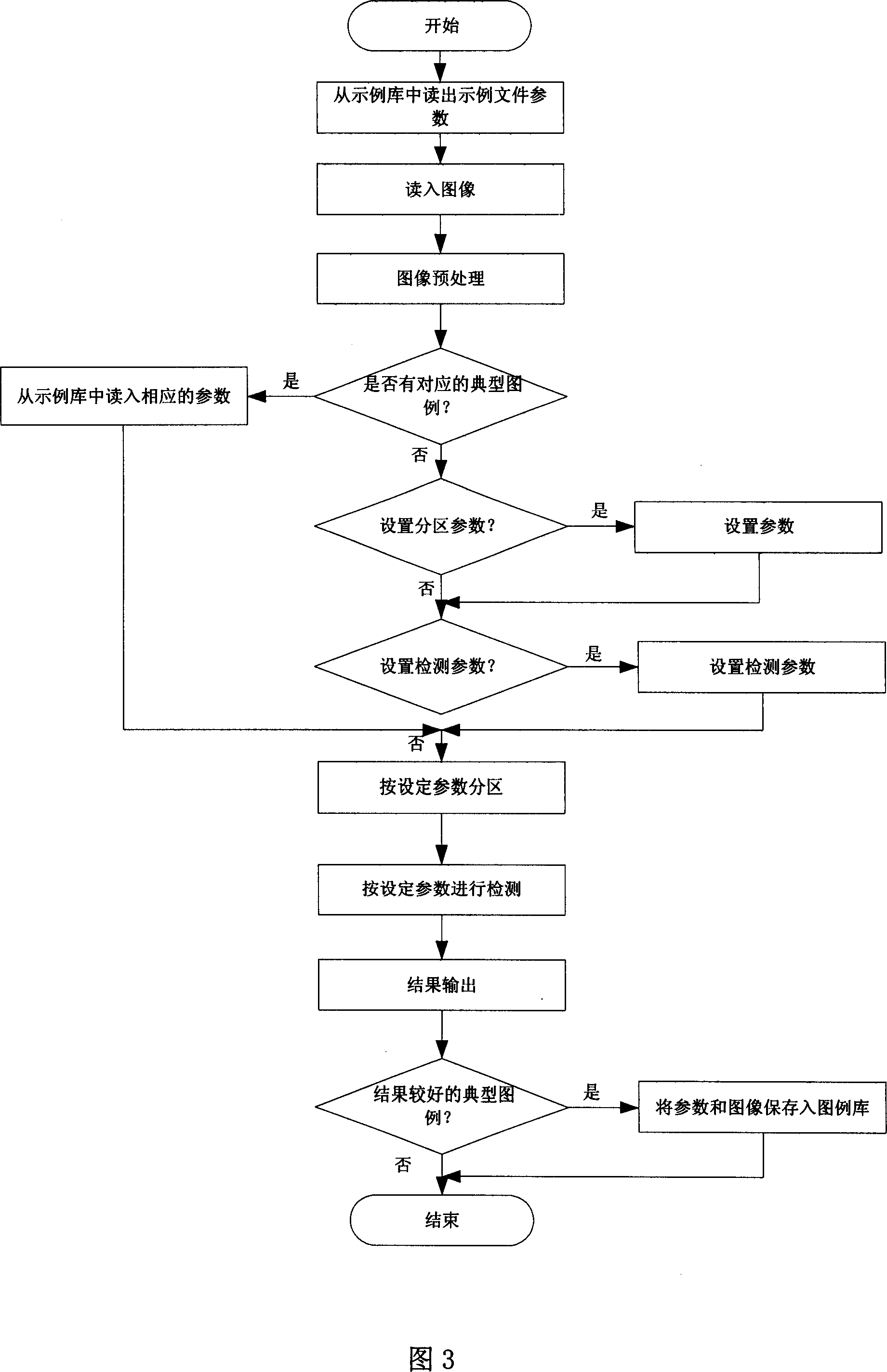

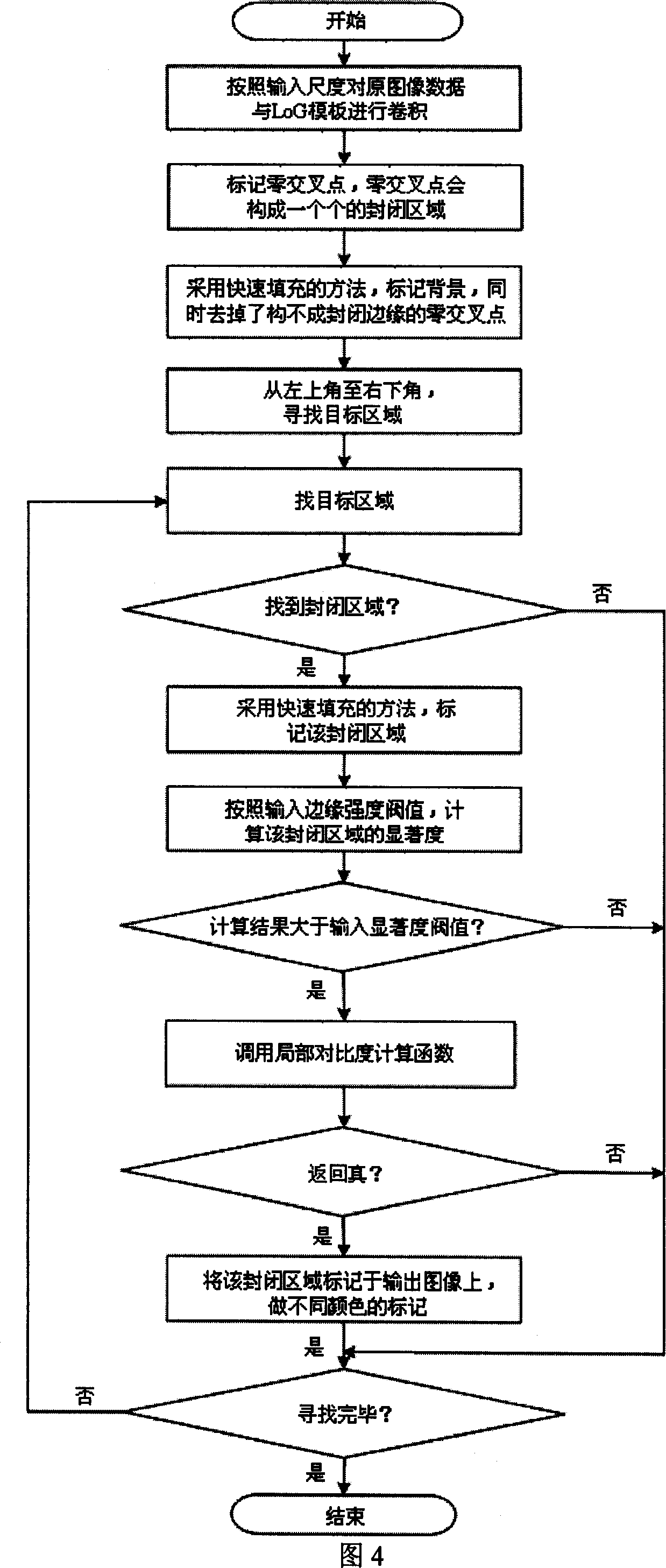

[0050] Using X-ray inspection, the internal defects of the printed circuit board are reflected as a flat image. The present invention specifically describes the method and system for automatic analysis and detection of internal defects of printed circuit boards through the analysis and identification of X-ray images of printed circuit board defects. The method and system of the present invention can be used to analyze and identify any Acquired images and graphics of internal defects in printed circuit boards.

[0051] The method and system of automatic analysis and detection of printed circuit board internal defects of the present invention can be realized by software, hardware or a combination of software and hardware, such as writing system processing software with Fortran and C language on a general-purpose computer to realize the method of the present invention, or using General-purpose or special-purpose DSP and a special-purpose accelerated processor on a general-purpose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com