Method and apparatus for testing a liquid crystal cell

A technology of inspection method and manufacturing method, which is applied to measuring devices, static indicators, instruments, etc., can solve the problems of uneven gap, difficult to form panels, uneven liquid crystal material 302, etc., and achieve the effect of high-precision inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

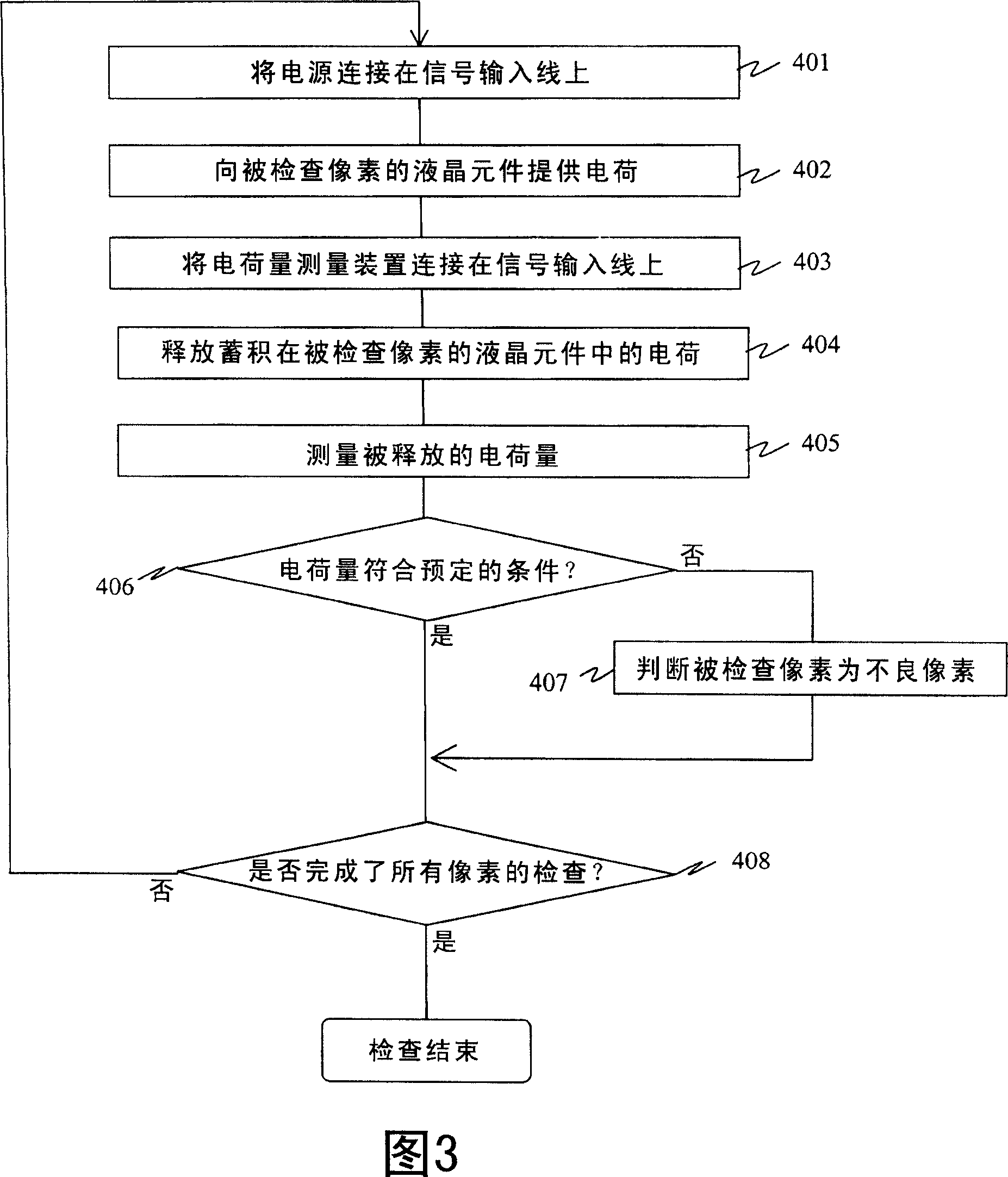

[0018] Hereinafter, typical embodiments of the present invention will be described with reference to the drawings.

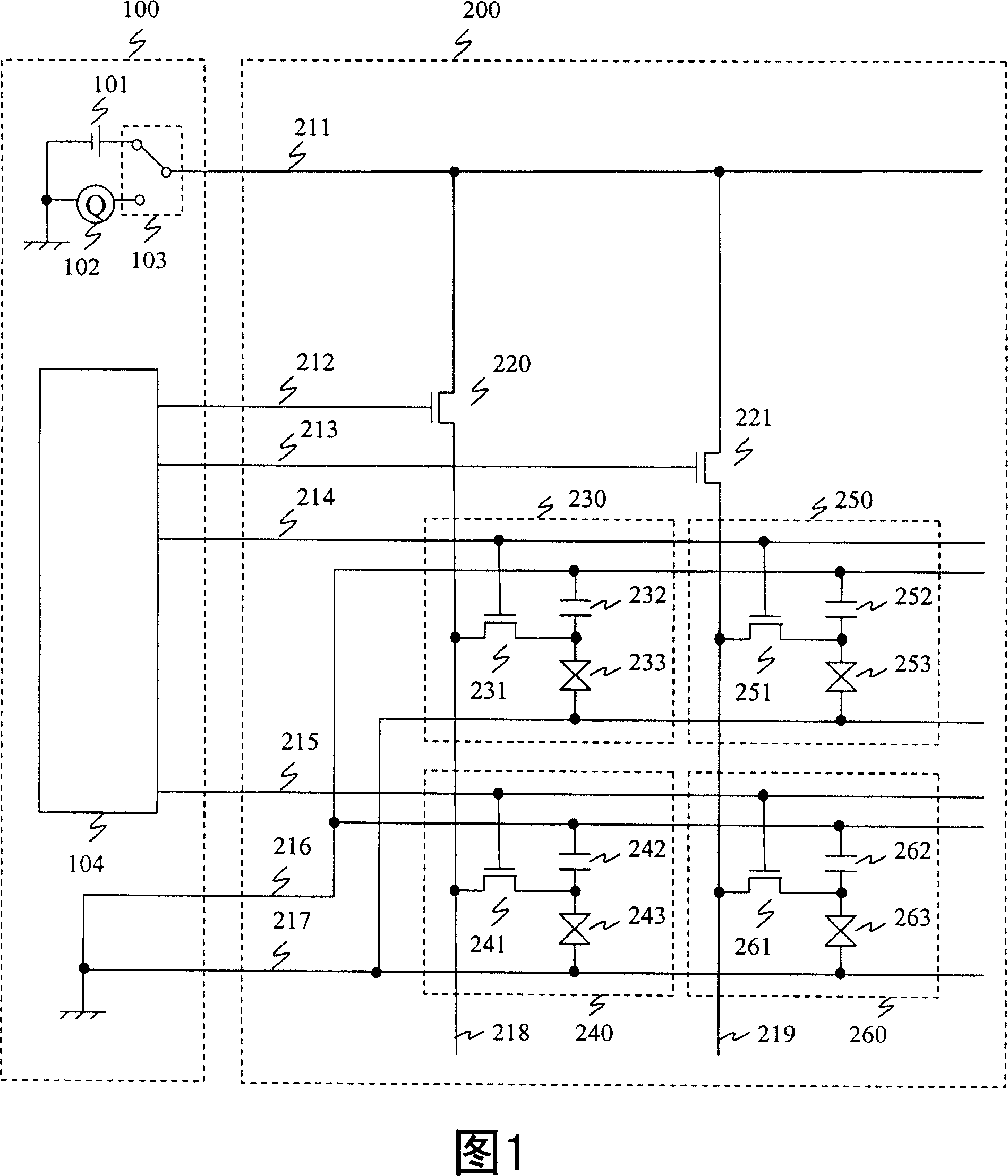

[0019] FIG. 1 is a schematic configuration diagram of a state where an inspection device 100 of the present invention is connected to a liquid crystal display panel 220 to be inspected.

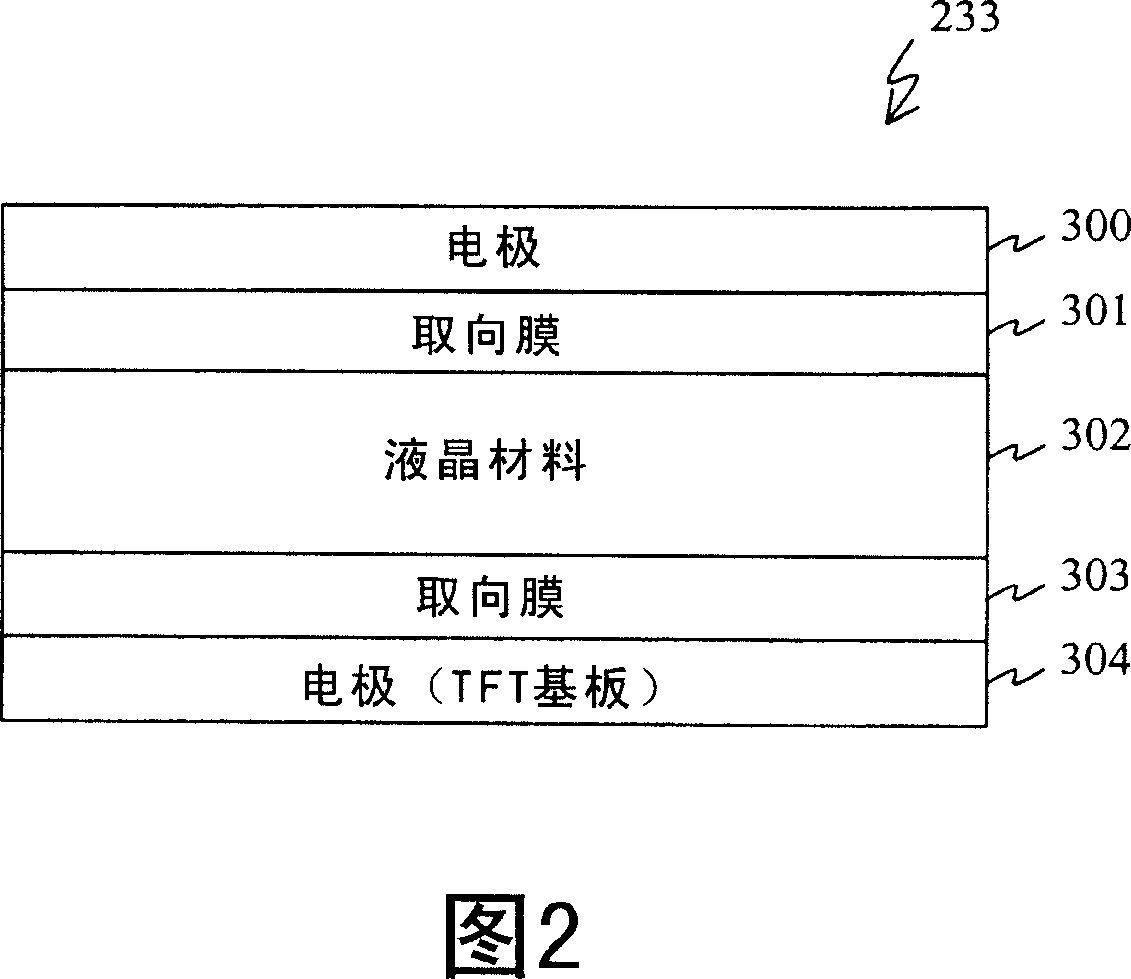

[0020] The liquid crystal display panel 200 is composed of the following parts: control lines 212, 213, 214, 215 for selecting pixels; Input control from the transistor 220 of the connection state between the signal input line 211 and the signal line 218 from the outside; According to the input of the control line 213, control the transistor 221 from the connection state between the signal input line 211 and the signal line 219 from the outside; Pixels (230, 240, etc.) disposed on intersections of control lines and signal lines; holding capacitor sharing lines 216 as reference potentials of holding capacitors (232, 242, etc.) of pixels; and liquid crystal elements (233, 243, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com