Method for detecting process quality using factor sieving

A factor and process technology, which is applied in the field of process quality inspection by factor screening, can solve the problems of inability to optimize the test and evaluation of the whole line, a large number of parameters, and small test volume, so as to maximize the use value of raw materials, scientific and accurate evaluation results, and improve technology. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

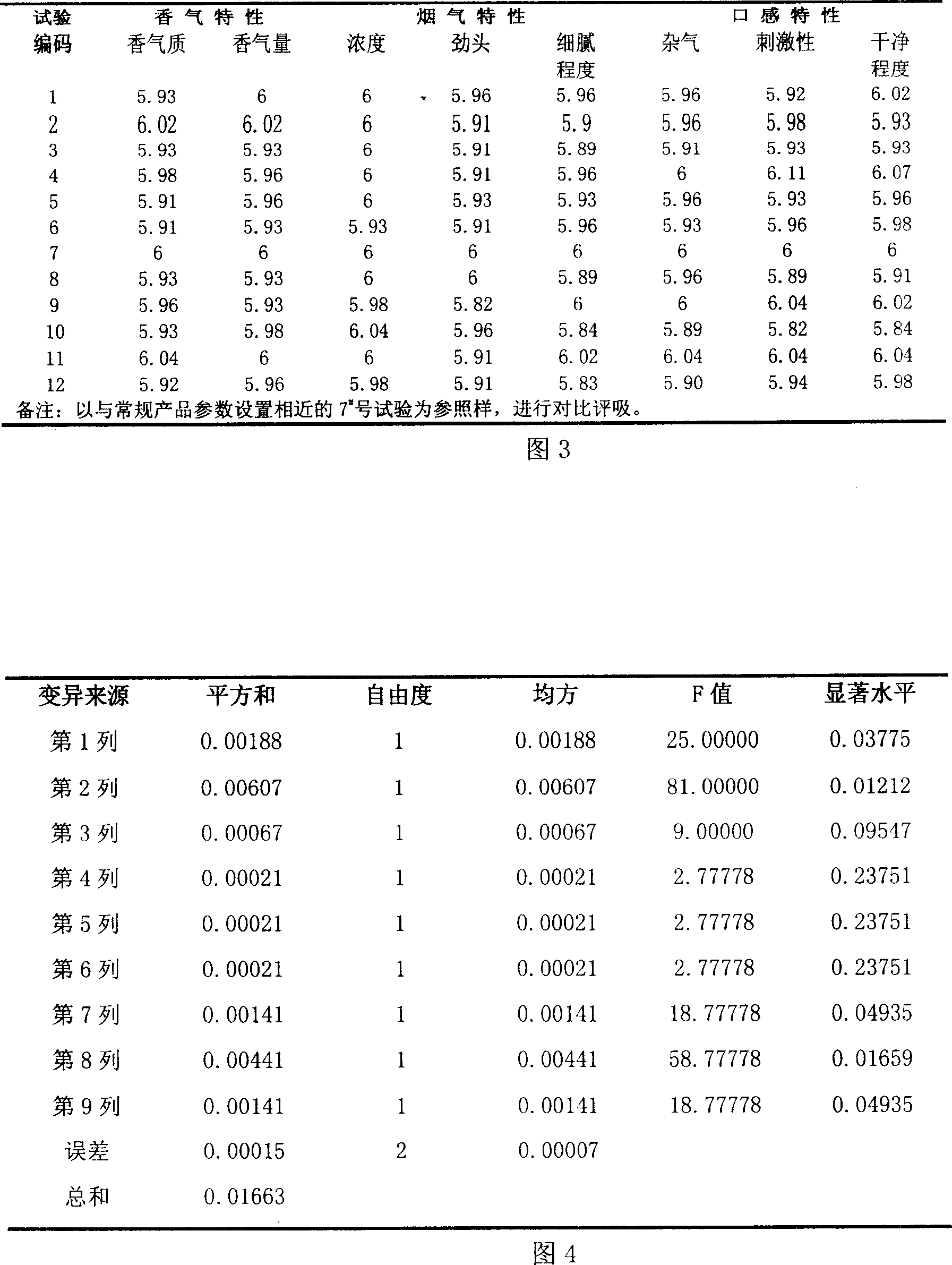

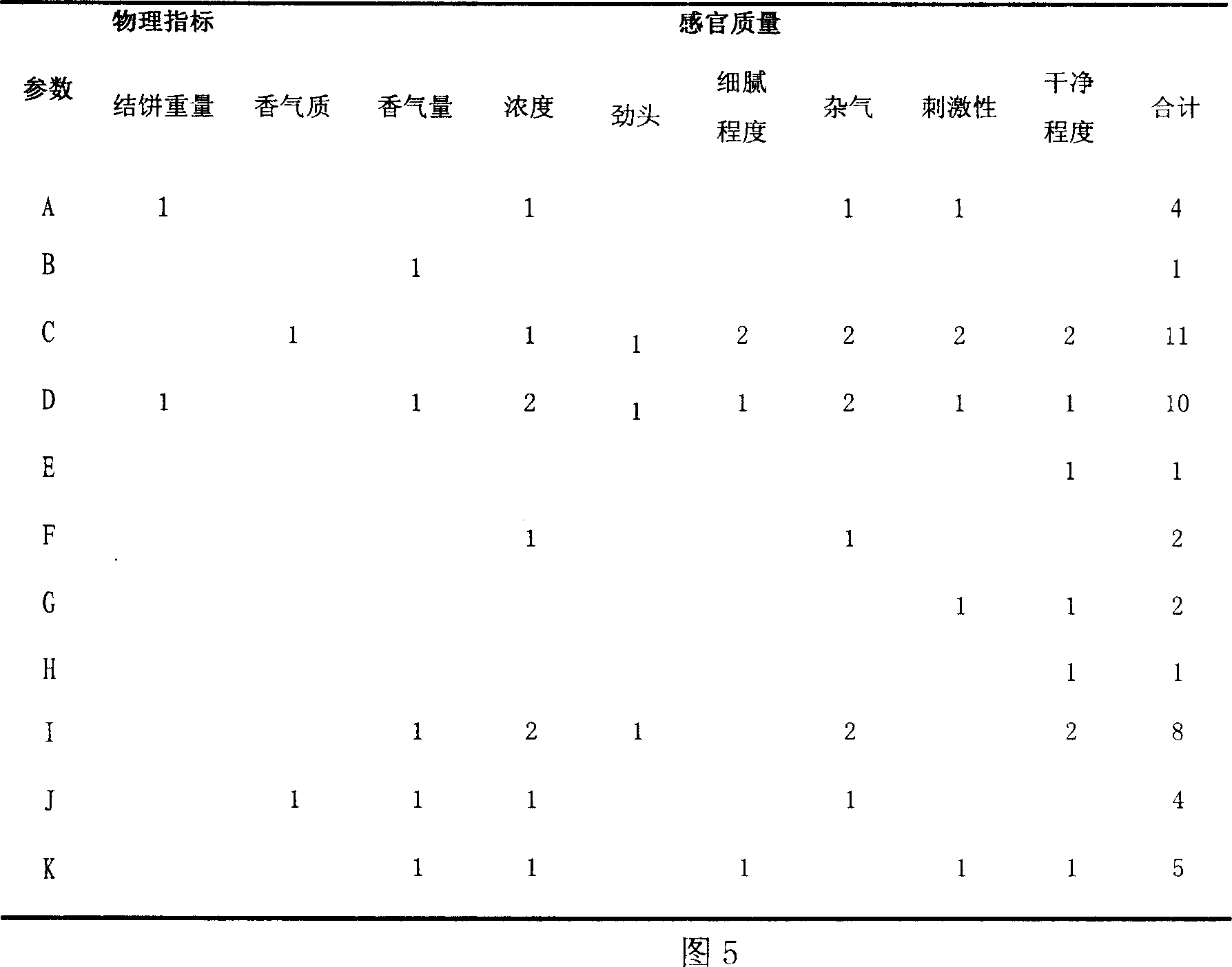

[0028] Taking the factor screening test of loose moisture regain and sieving and feeding process as an example, the application of factor screening in process quality evaluation is introduced in detail.

[0029] First of all, choose a formula of three types of flue-cured tobacco leaves of a certain brand; WQ3116A loose moistening machine and SJ1525 feeding machine as the equipment for the process. RAYMX2C infrared thermometer, TM710 infrared moisture meter, and CJ201 leaf vibration sorting screen are used as process quality inspection instruments.

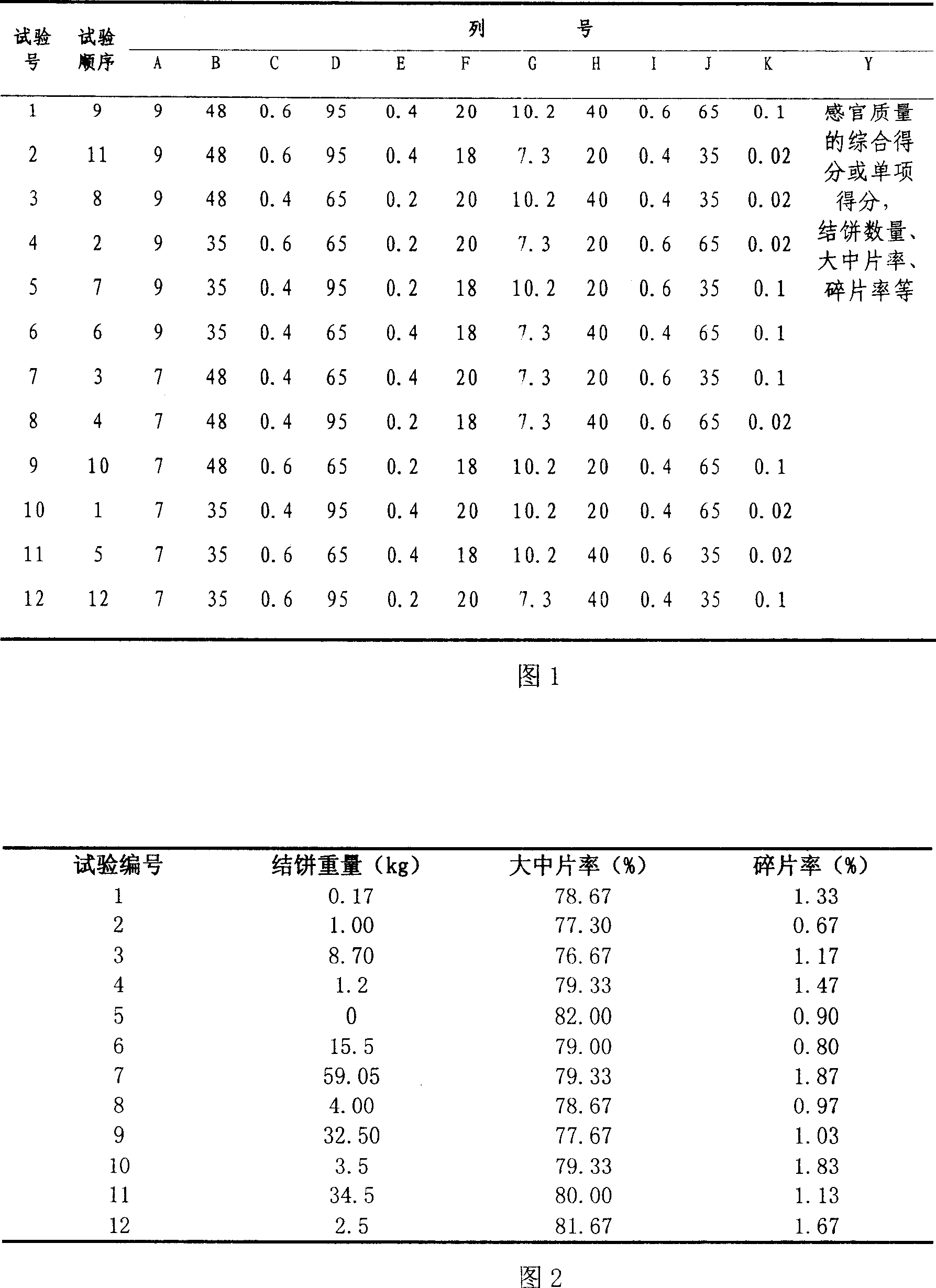

[0030] Then, take the 11 parameters of the two processes of loosening and moistening the tobacco sheets and moistening the leaves as 11 factors, select their average or standard values as a level within the range of equipment capabilities, and select values close to the upper limit or lower limit within the range of equipment capabilities As another level, use the principle of orthogonal test to design a set of 11 factors and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com