Modular wall construction system for aircraft cabins

A modular, structural technology that is used in aircraft cabins to solve problems such as inability to provide room size or room geometry flexibility, and difficulty in installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

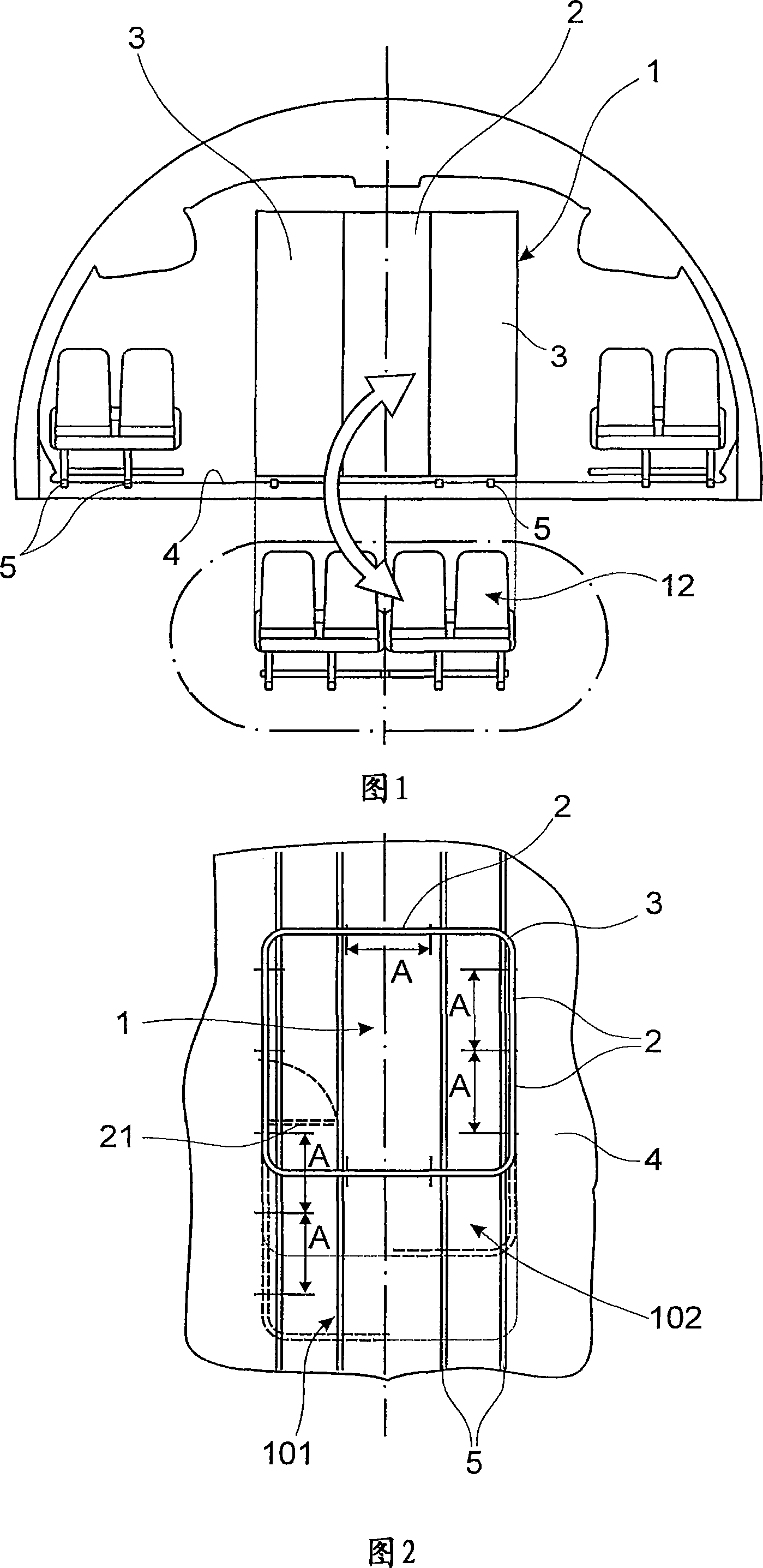

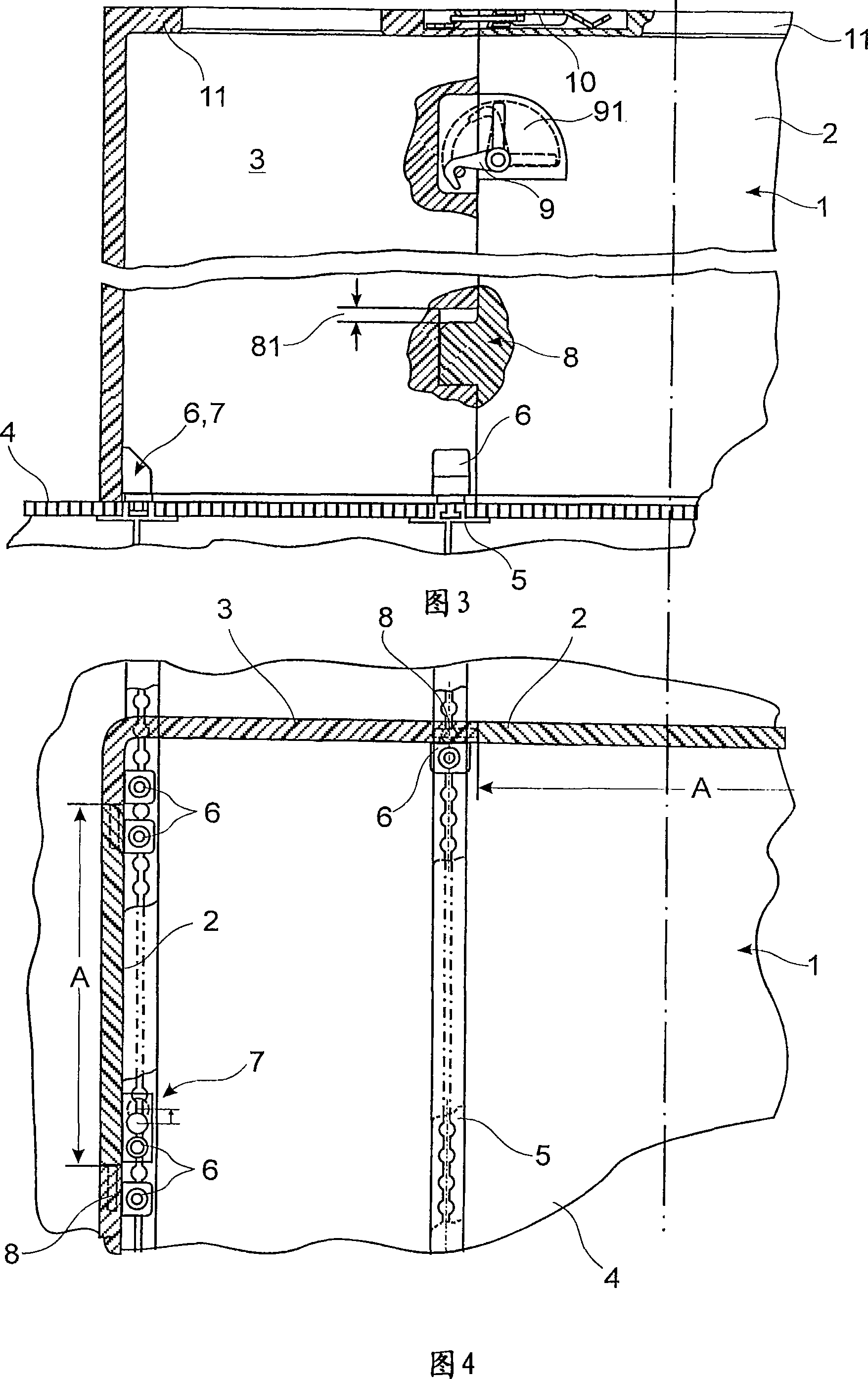

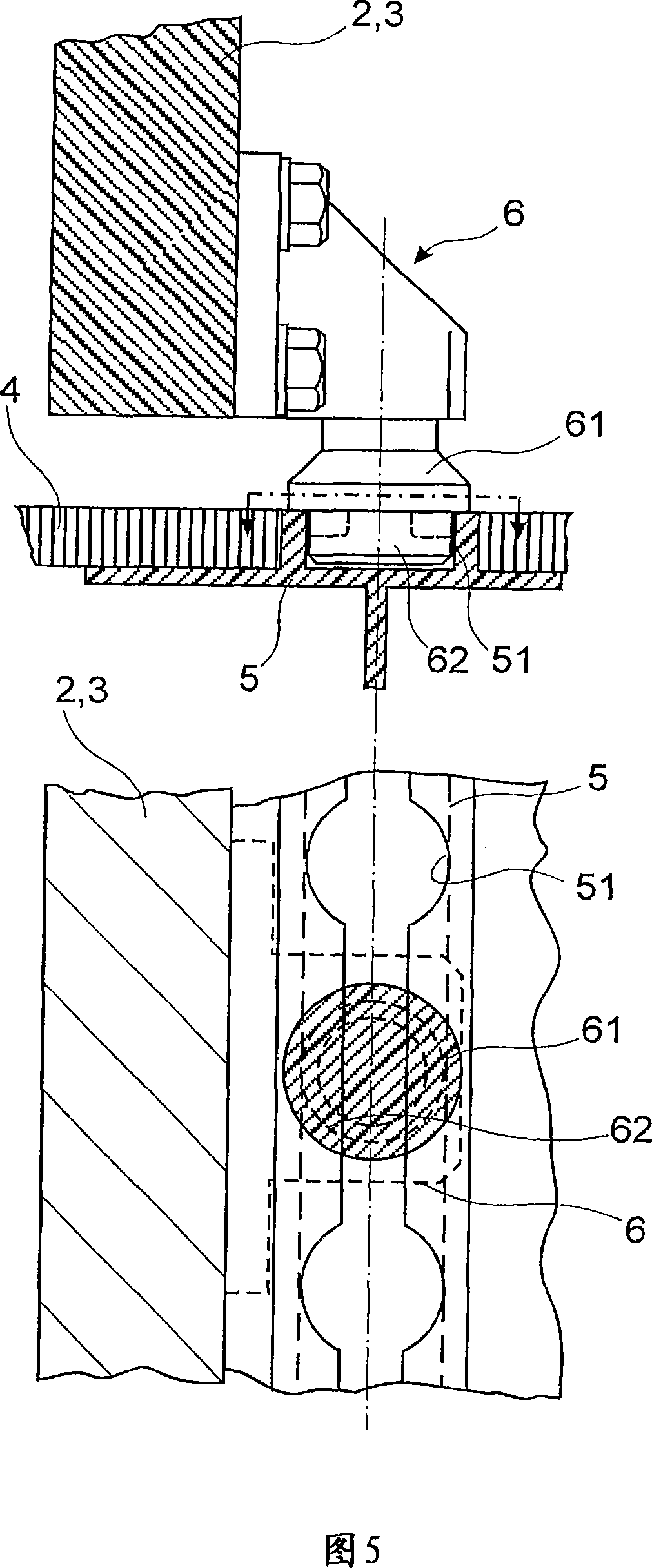

[0038] FIG. 1 shows a cabin cross-section of a commercial aircraft with a centrally installed cabin unit 1 comprising a wall segment according to the invention. In this arrangement, the chamber unit 1 comprises side wall segments 2 and corner wall segments 3 . The attachment of the segments is entirely within the seat rail 5 extending in the cabin floor 4 . Due to the inherently stable wall design with mutually supporting wall segments 2 , 3 it is sufficient to attach the segments in the seat rail 5 . Thus, no further attachment points, eg on the ribs of the aircraft or on the ceiling of the cabin, are required. Furthermore, the segments can be high enough that the room unit 1 does not need a ceiling for reasons of visibility, which is a factor which further facilitates quick installation. Arrows in the figures indicate an optional installation of a passenger seat 12 instead of the cabin unit 1 . The individual wall sections 2, 3 can be made of sandwich panels of lightweigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com