A tool dedicated for build-up welding of magnetic medium

A special tool and magnetic medium technology, which is applied in the field of metallurgy and mineral processing, can solve problems such as very small intervals, large welding deformation, and magnetic medium welding failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

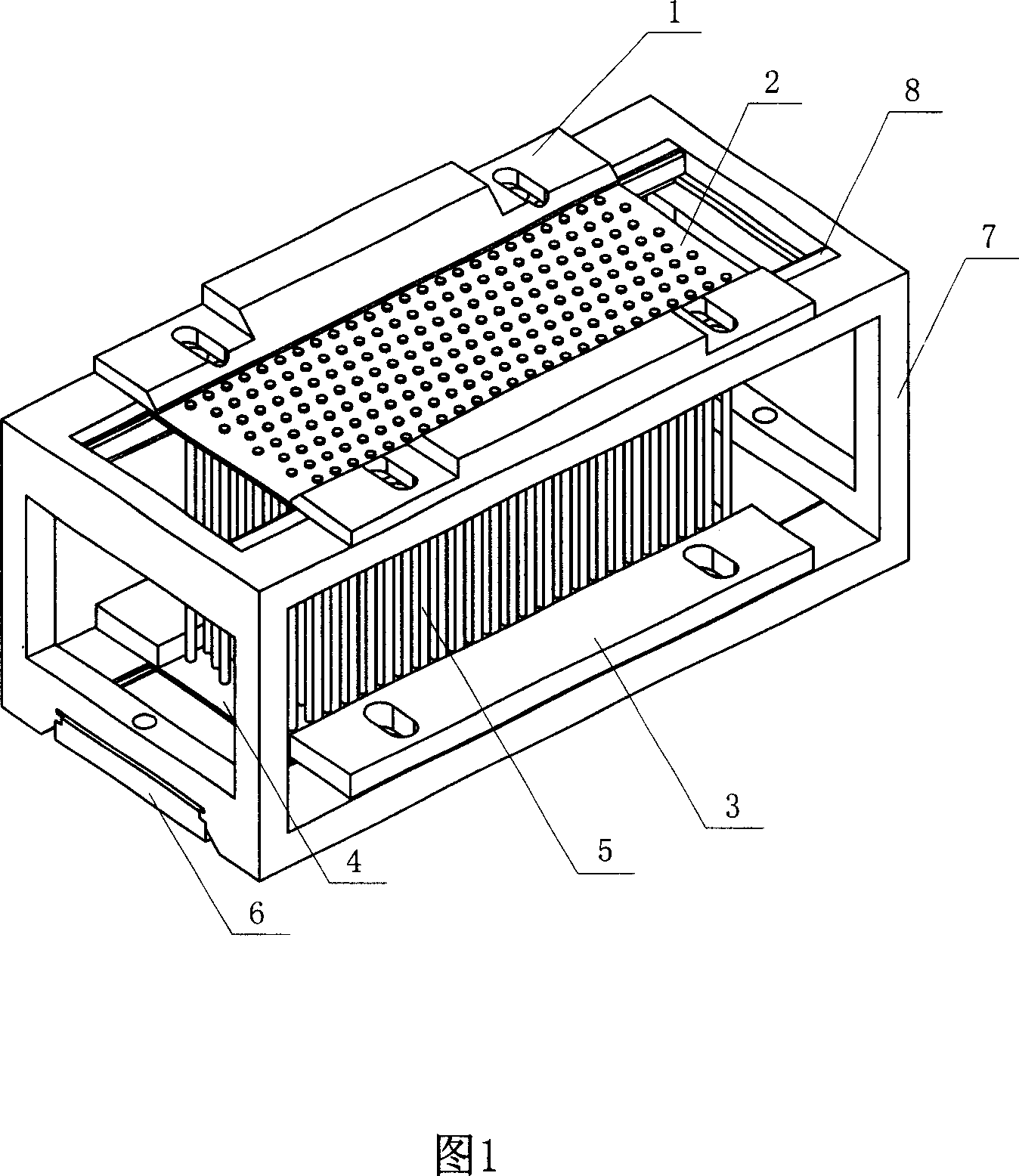

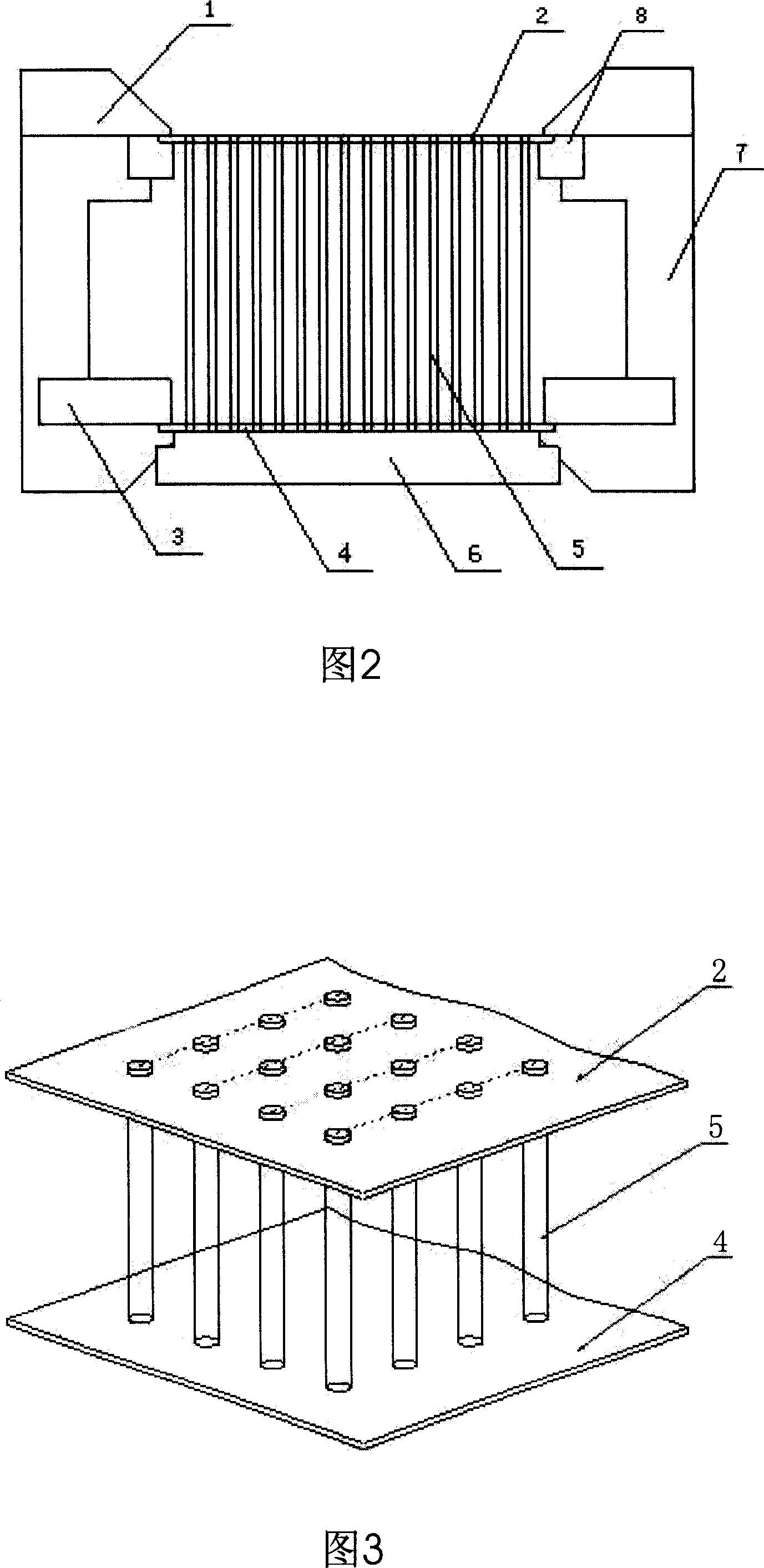

[0010] As shown in Figures 1 to 2, the magnetic medium build-up welding special tool according to the present invention includes a frame 7, a lower support block 6, a lower pressure block 3, an upper support block 8, and an upper pressure block 1, wherein the frame 7 The middle part is provided with a cavity that can accommodate the magnetic medium stack as shown in Figure 3, and the lower support block 6 is slidably installed on the bottom of the frame 7 to support the lower stainless steel plate 4 of the magnetic medium stack and prevent each medium rod 5 from The lower stainless steel plate 4 slides out from the perforation, and the lower pressing block 3 is detachably installed on the bottom plates on both sides of the frame 7 by bolts to be used to embed the two sides of the lower stainless steel plate 4 of the magnetic medium stack to avoid the lower stainless steel plate. Deformation occurs during the welding process; the upper support block 8 is installed on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com