Moreover, unlike manufacturing that involves the repeated

mass production of similar items using the same process, construction usually involves a uniquely designed project that is built in accordance with a one-of-a-kind plan by a large number of people whose actions

impact the actions required by other workers who are not accustomed to working with each other, and are unaware of the exact sequence for the interrelated work.

But, they also must

problem solve at the

work site since reality may riot coincide with what is set forth within the drawings or specifications.

If one process step is conducted improperly or delayed in its installation, it may

delay the next process step conducted by another worker that will lead to missed construction deadlines and cost overruns.

Current estimates indicate that $15 billion is wasted each year by construction inefficiencies.

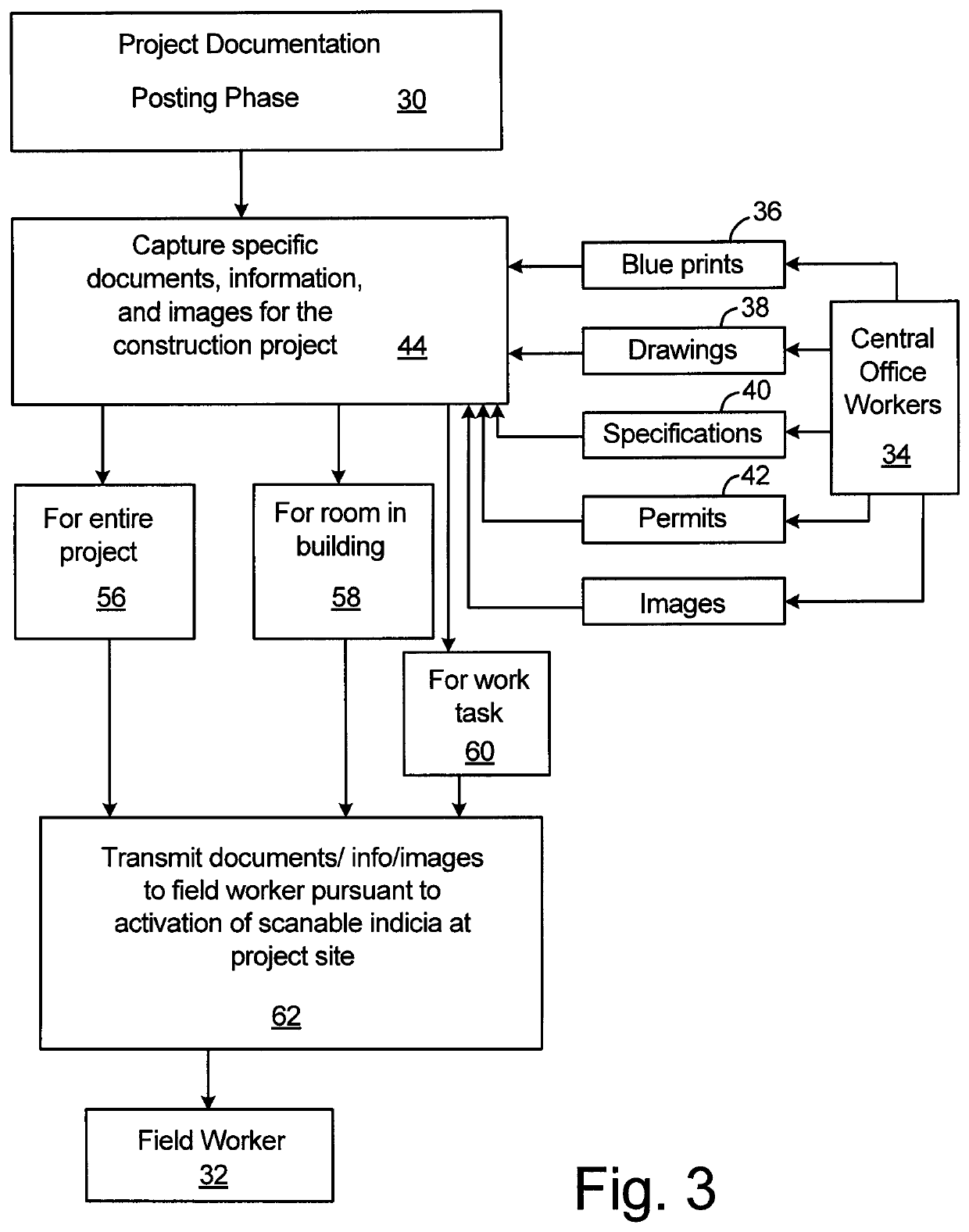

A common problem for construction projects is the need by the architects to modify the drawings while the building is being constructed.

This creates the risk that contractors or subcontractors may be operating off of obsolete drawings.

Another challenge is to manage the construction activities at a building project site where a number of different laborers and skilled craftsmen may be working side-by- side.

But while such face-to-face meetings may provide for efficient communication of information for these construction tasks and their staging at the project site throughout that day, such meetings do not permit the plans and tasks to be modified throughout the work day.

However, this appears to be merely an information

collection system without any dynamic

processing of the information to produce improved field maps and other guidance documents for assisting the field crews at the project site.

However, work assignments made at the beginning of the day may need to be modified during the day in response to unforeseen variables.

Construction materials may not be delivered to the project site on time.

One

work task at the project site may become delayed, thereby impeding the start of a second

work task that is dependent upon the completion of the first

work task.

Another challenge arises at project sites as workers encounter problems that were not anticipated by the blue prints and other design documents.

This could comprise, for example, misalignments in the design plans, or something previously installed that interferes with a second object that needs to be installed.

While the general. contractor may halt a specific assigned work task in response to the problem until the matter can be discussed with the

project manager at the next

morning's central meeting, this is inefficient and will slow down the construction project.

Such real-time trouble shooting enhances the construction process, but. can also slow down the process if the centralized decision makers are unavailable or take too much time to review the information sent by the field workers.

Yet, speed to resolve open questions from the field workers is imperative as a construction project represents a

chaotic environment with numerous changes to the physical environment occurring daily.

This means that if the field worker does not have or remember his

password, then he cannot access the system.

Another potential problem for the field worker is to wade through a large volume of information and documents stored inside the

computerized system to examine and determine what he needs.

But without possession of such identifying information, it may be next to impossible for a field worker to retrieve the needed documents or information.

Another potential problem is posed by the shear magnitude of the information or documents stored within the system for the construction project.

But such a system requires a large amount of coding of information and sensors located at the project site for detecting the worker's identity, location, etc.

But such systems require a large number of RFID tags and are limited by the worker's

accessibility to the construction materials, themselves.

However, these systems require not only a large number of QR codes to cover all of the drawings and other documents for the construction project, but also some kind of means like a. binder located at the

work site for the field worker to look up the QR code associated with the specific drawing or document of interest before they may be scanned and accessed from the system.

However, none of these computerized systems for construction

project management provide ready access by a field worker to needed information and documents for a specific project task without complicated

password security protocols and the need to search through a large number of stored documents and information for the overall project, or a large number of QR codes, RFID tags, barcodes, etc. associated with such documents and information files in order to identify and

gain access to the needed information or documents.

Login to View More

Login to View More  Login to View More

Login to View More