Protective garment material

a technology of protective garments and garments, applied in protective equipment, special outerwear garments, clothing, etc., can solve the problems of affecting the safety of workers, and exposing police, watchmen and other security personnel to injuries of this kind, so as to achieve superior protection, mobility and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

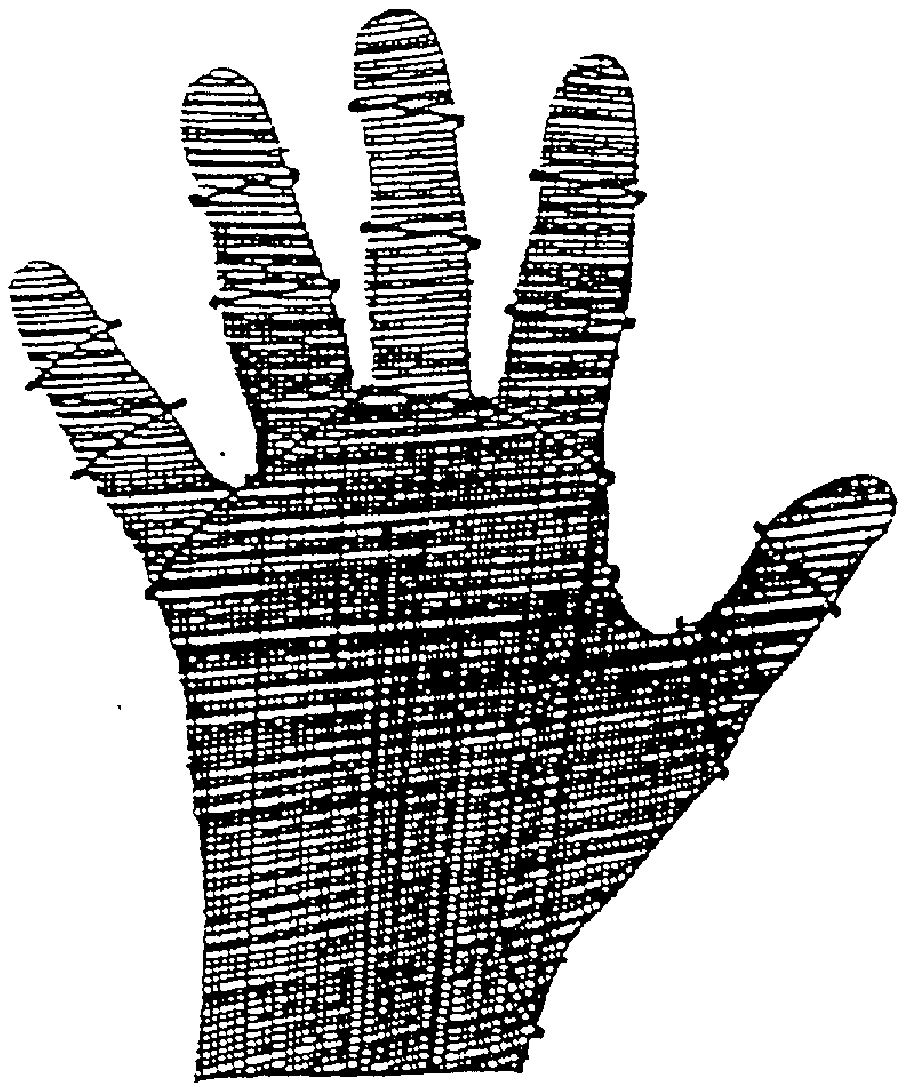

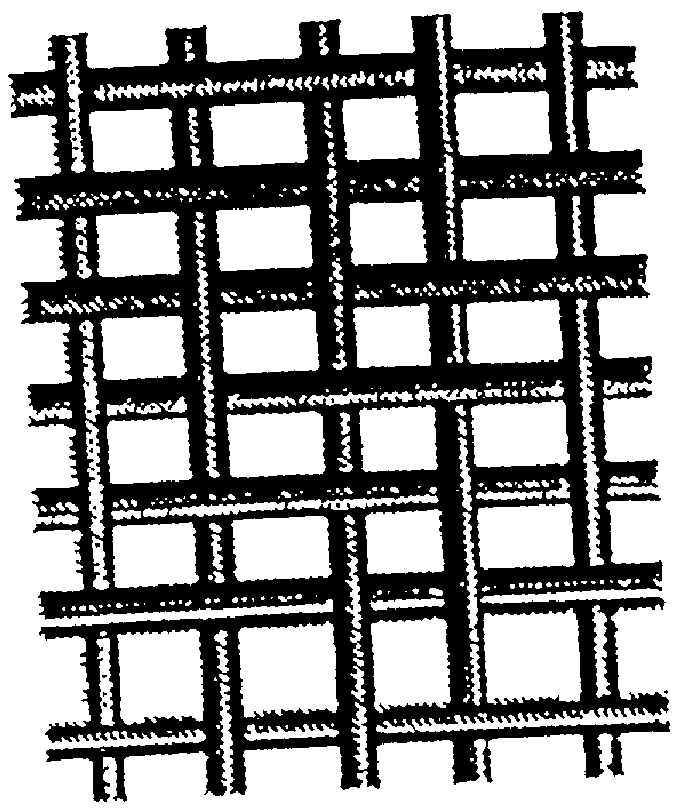

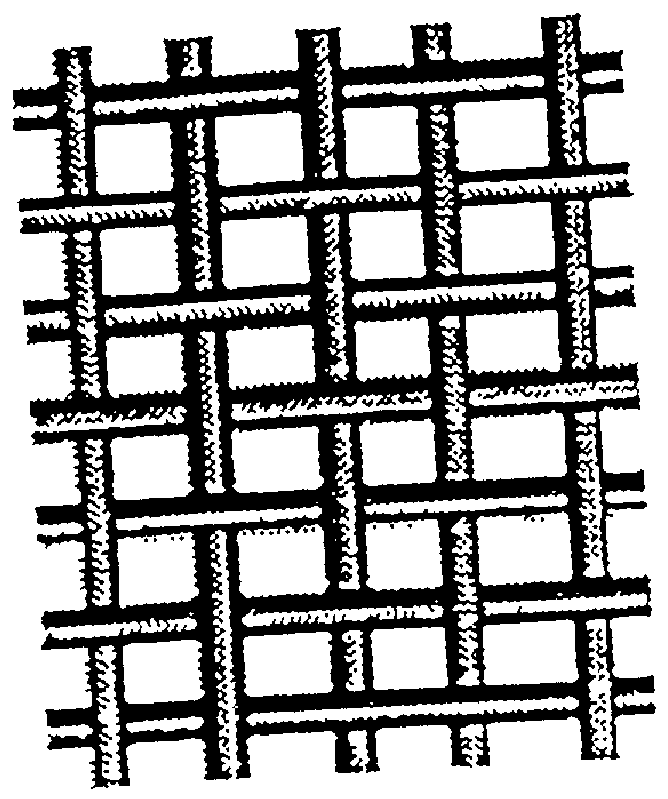

[0042] FIG. 1 illustrates sections of two types of wire mesh for use as a protective layer in a protective garment according to the invention. In a preferred embodiment, indicated by A, the wire mesh is plain woven and consists of stainless, non-corrosive steel, quality AISI 316. The dimensions of mesh A are, by example, 0.05 mm in wire diameter and 0.077 mm in the mesh's aperture. Mesh B shows one of several examples of a wire mesh of an alternative weaving, a so-called Twill weaving, which may be used as a protective layer in a protective garment according to the invention. Further examples of suitable, alternative weavings are Dutch Plain weaving, Dutch Twill weaving and others. It should be noted that although the wire comprising the wire mesh in the preferred embodiment is described as being, by example, 0.05 mm, other diameter wire may be used, so long as it is sufficiently strong so as to remain intact during slashing or piercing contact with sharpened or pointed instruments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com