Method of manufacturing a contact plug in a semiconductor device

a technology of contact plugs and semiconductor devices, which is applied in the direction of semiconductor devices, electrical devices, transistors, etc., can solve the problems of increasing resistance, difficulty in applying polysilicon that has been used difficulty in using polysilicon as a contact plug, so as to improve the electrical characteristic of the device and prevent the effect of increasing resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The disclosed method will be described in detail by way of a preferred embodiment with reference to accompanying drawings, in which like reference numerals are used to identify the same or similar parts.

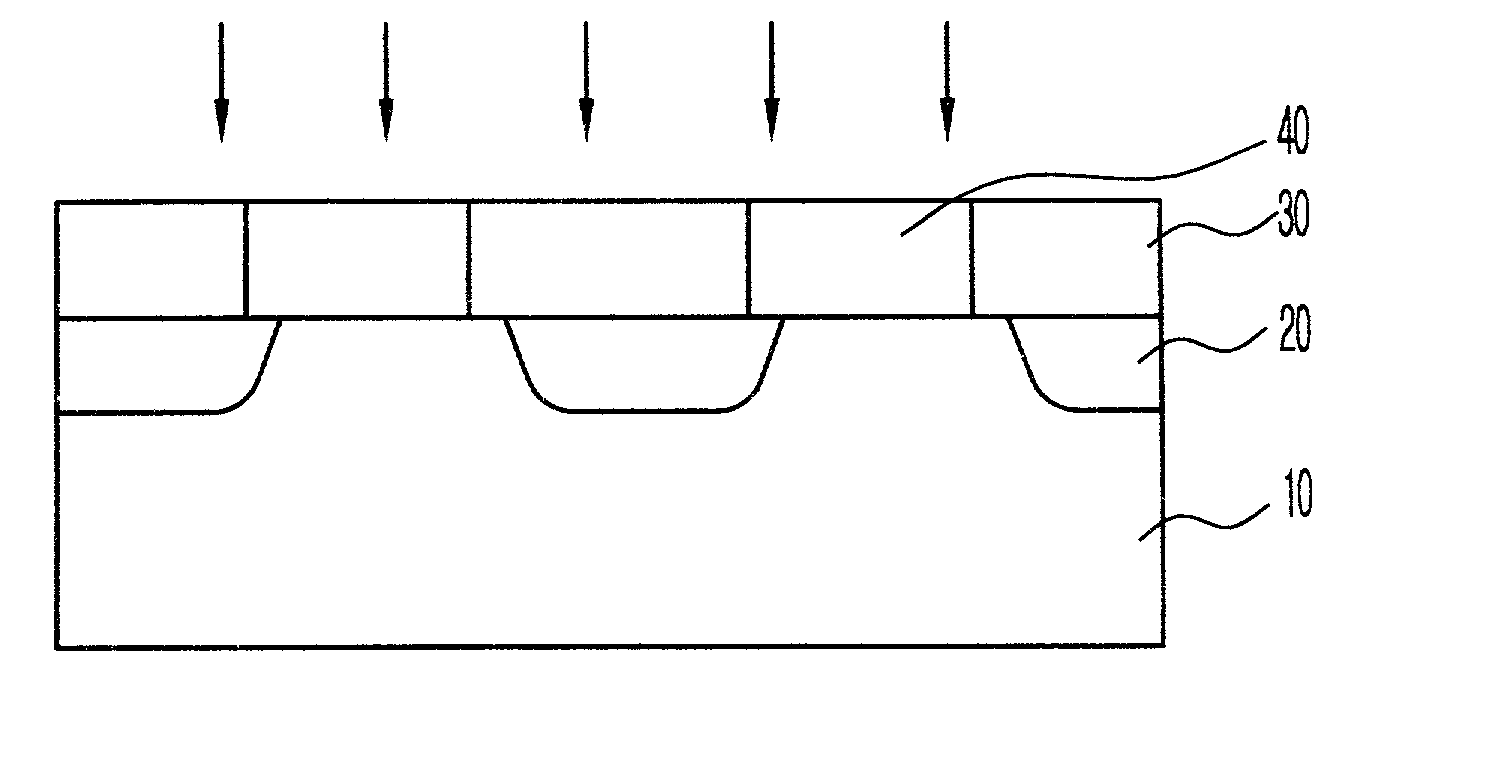

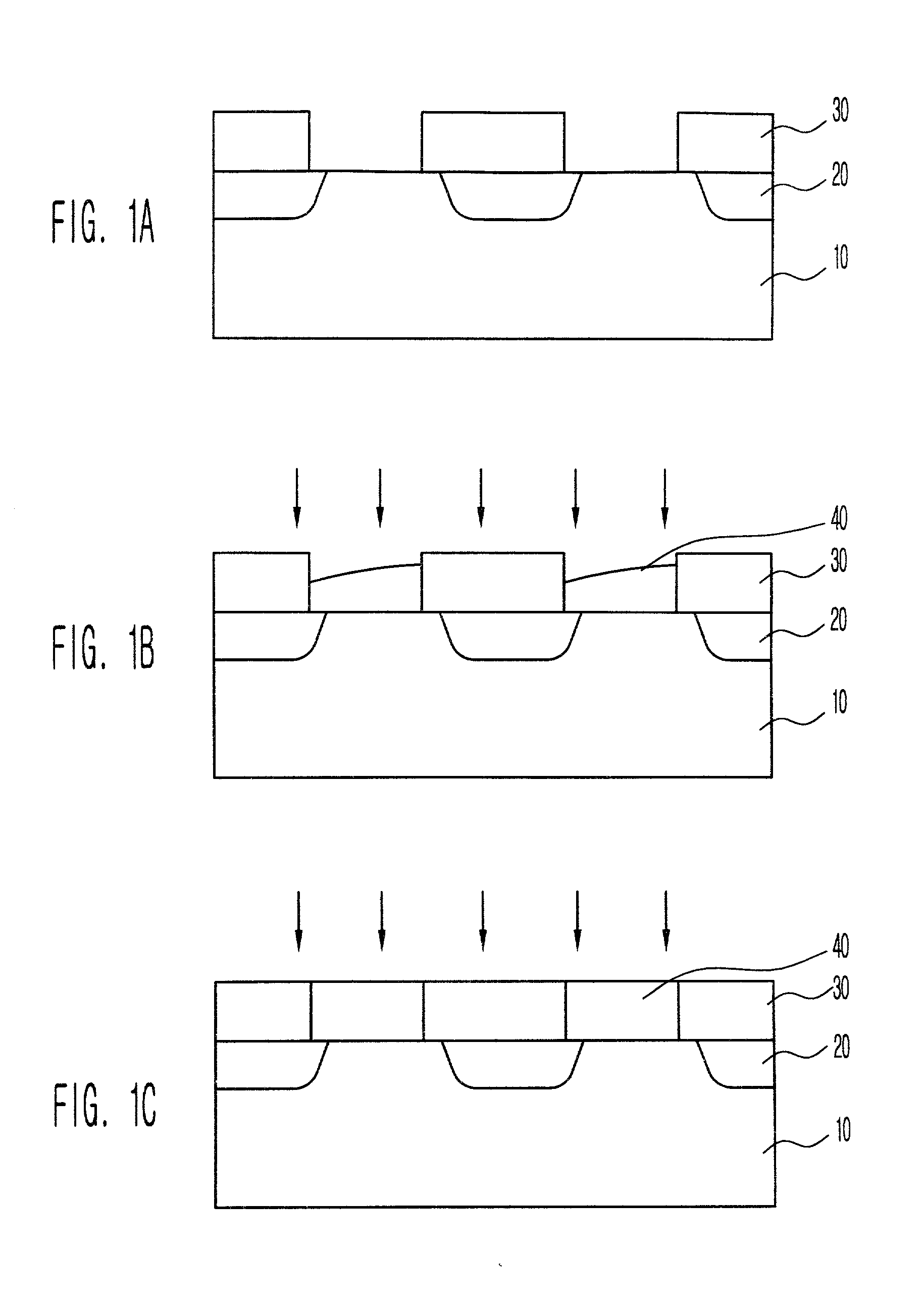

[0014] FIGS. 1A to 1C are cross-sectional views for explaining a method of manufacturing a contact plug in a semiconductor device according to the disclosed methodology.

[0015] Referring now to FIG. 1A, an interlayer insulating film 30 is formed on a semiconductor substrate 10 in which a device separation film 20 is formed. Then, the interlayer insulating film 30 is patterned to expose the junction surface of the semiconductor substrate 10, thus forming a contact hole.

[0016] Referring now to FIG. 1B, impurity is thermally doped into a SEG silicon layer for contact plug 40 while the SEG silicon layer for contact plug 40 is grown on the exposed surface of the semiconductor substrate 10. The thermal doping is performed when the SEG silicon layer for contact plug has been initially...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap