Stage apparatus, scanning type exposure apparatus, and device produced with the same

a technology of scanning type and exposure apparatus, which is applied in the direction of photomechanical apparatus, instruments, printing, etc., can solve the problems of large wafer stage for holding the wafer, reverse deterioration of throughput, and inability to perform scanning exposure,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

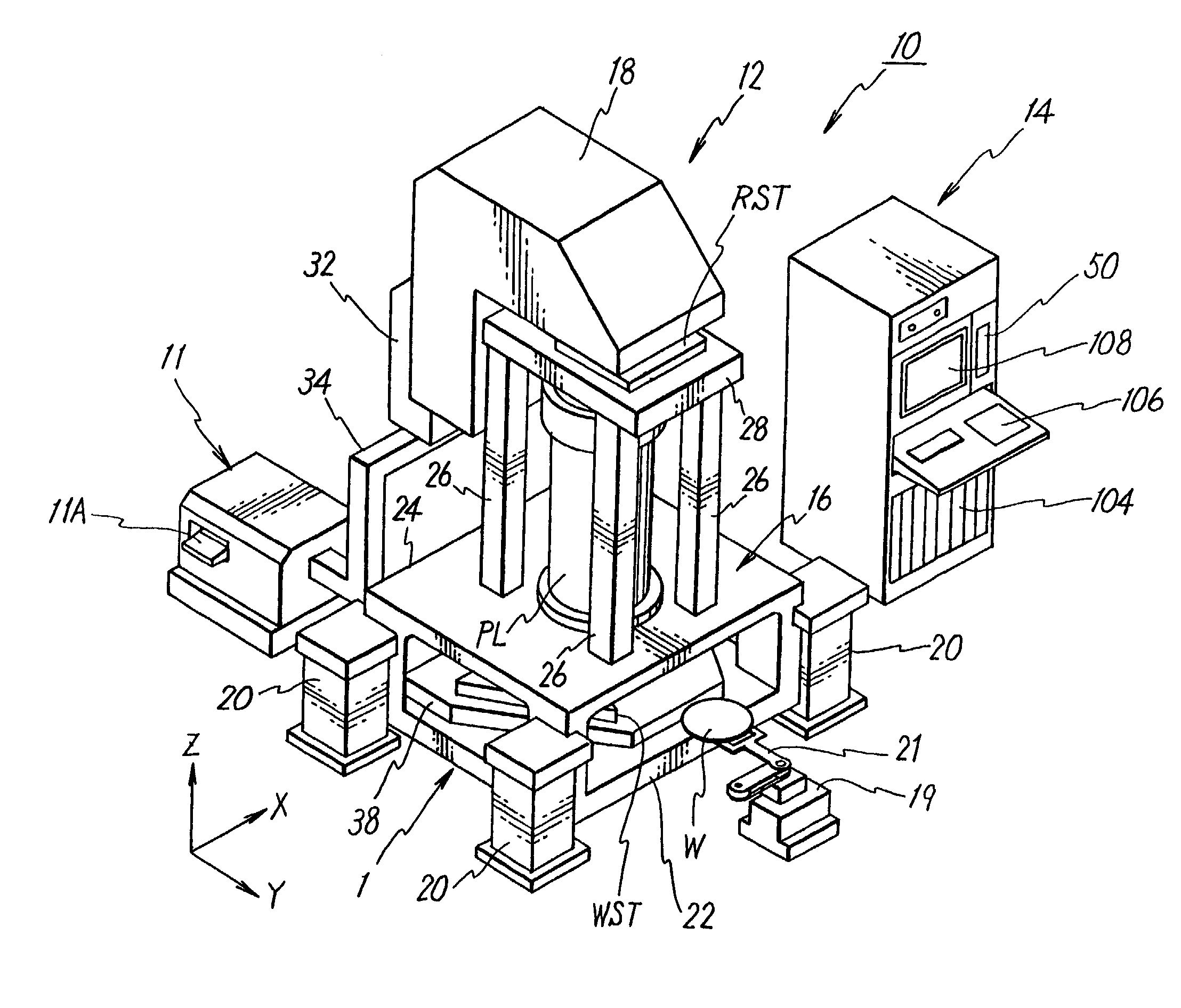

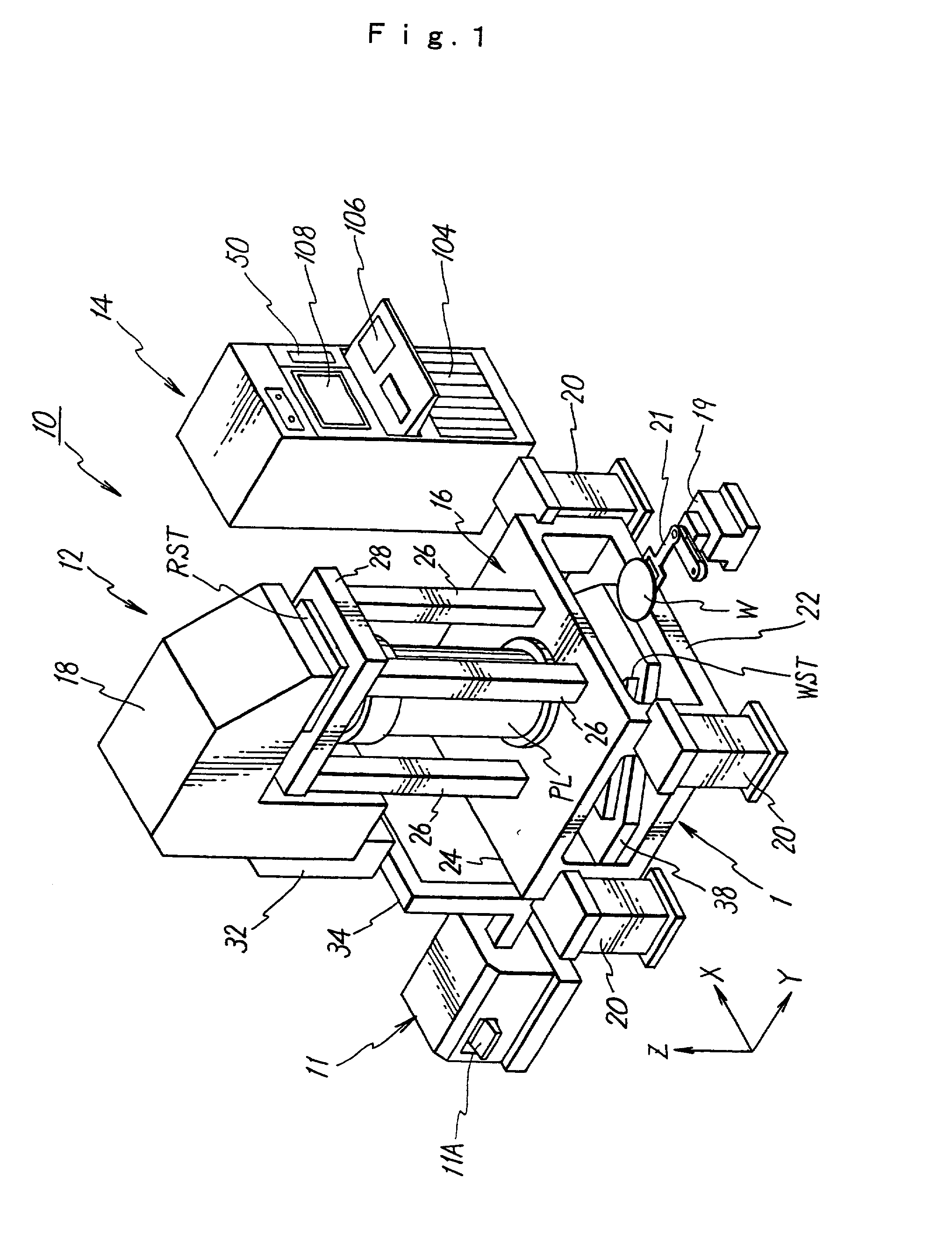

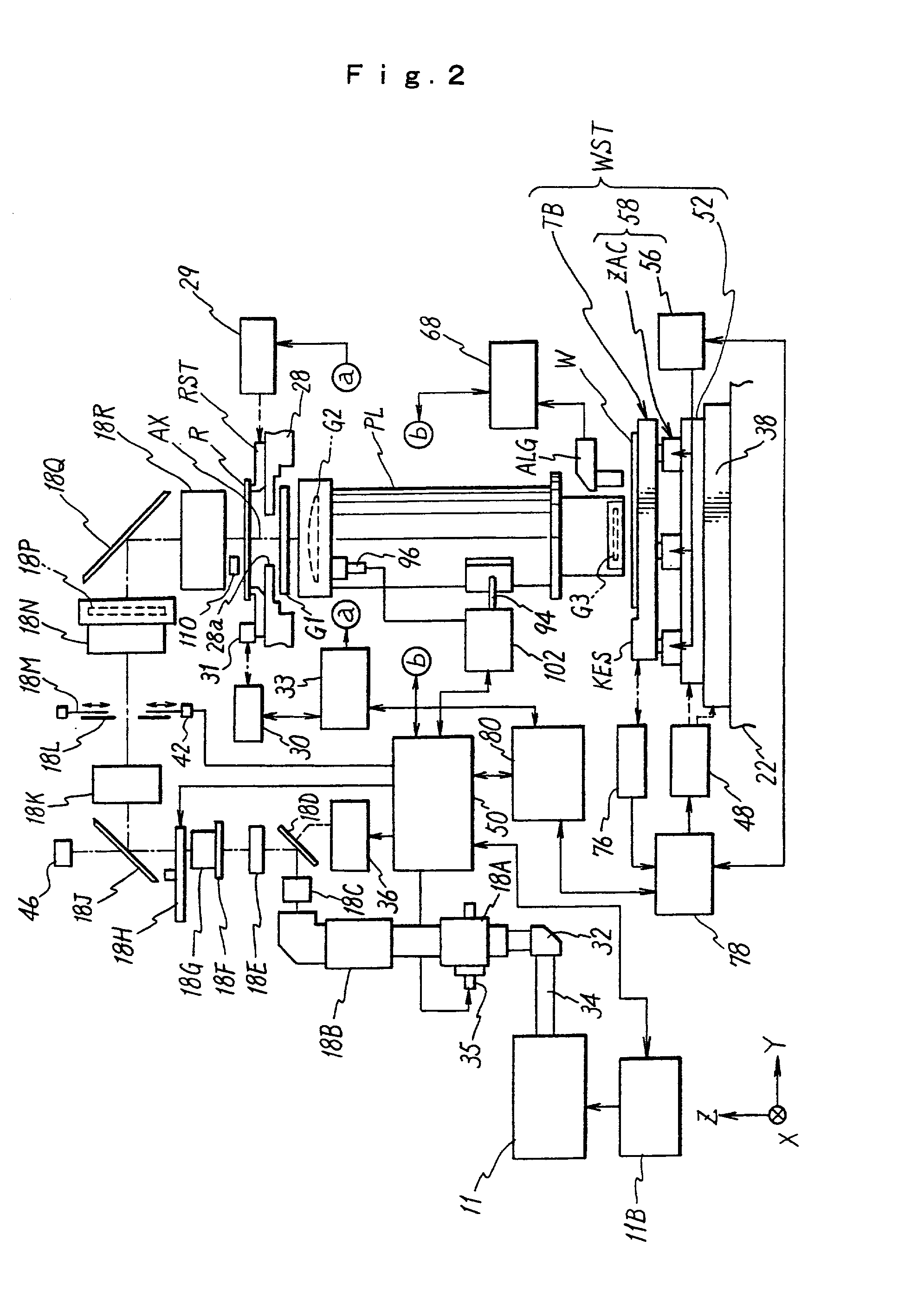

[0234] In the first embodiment, the first to fourth concepts are specified. FIG. 1 shows a perspective view illustrating a scanning type exposure apparatus 10 according to an embodiment of the present invention. FIG. 2 schematically shows an internal arrangement of the scanning type exposure apparatus 10. The scanning type exposure apparatus 10 is a projection exposure apparatus for performing the exposure operation in accordance with the step-and-scan manner which is being dominantly used as a lithography apparatus for producing semiconductor devices. The scanning type exposure apparatus 10 transfers an entire circuit pattern on a reticle R to a plurality of shot areas on a wafer W respectively in accordance with the step-and-scan manner by relatively scanning the reticle and the wafer W in the one-dimensional direction (Y direction in this case) with respect to the field of a projection optical system PL while projecting a part of the circuit pattern depicted on the reticle R as t...

second embodiment

[0461] Next, the second embodiment of the present invention will be explained with reference to FIGS. 21 to 25. The second embodiment especially discloses the second to fifth concepts of the present invention.

[0462] FIG. 21 shows a schematic arrangement of an exposure apparatus 110 according to the second embodiment. The same components as those of the first embodiment described above or components equivalent thereto are designated by the same reference numerals, explanation of which will be simplified or omitted. The exposure apparatus 100 is a projection exposure apparatus based on the so-called step-and-scan manner.

[0463] The exposure apparatus 110 comprises, for example, a stage apparatus 101 which is provided with two square wafer stages WST1, WST2 as the first movable members for making movement in the two-dimensional direction while independently holding wafers W1, W2 as the substrate respectively, a projection optical system PL which is arranged over the stage apparatus 101,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com