Paper tube with flange

a paper tube and flange technology, applied in the field of paper tubes with flanges, can solve the problems of inconvenient use of bobbins made of synthetic resin, heavy bobbins made of wood, and inability to be recycled,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

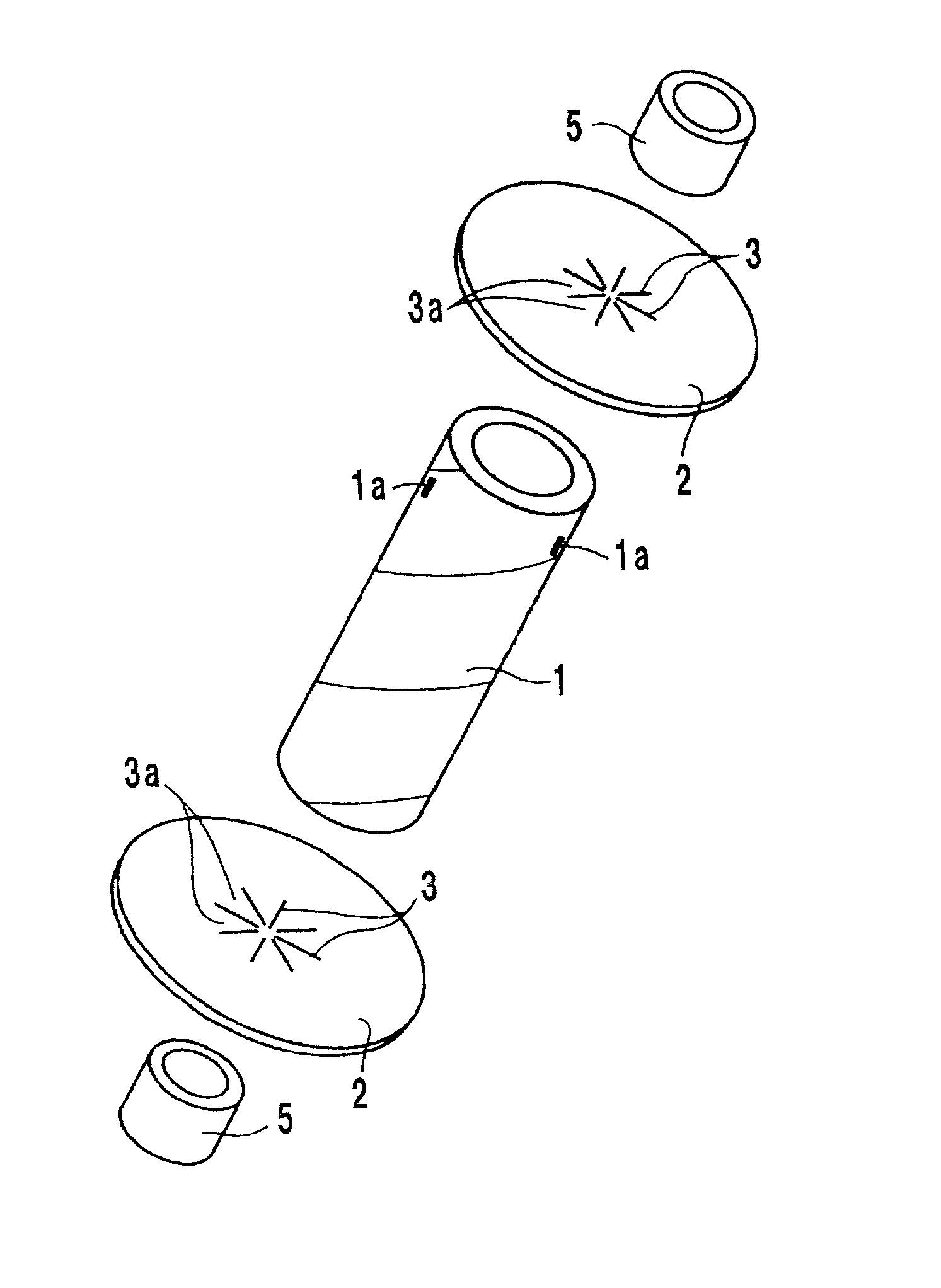

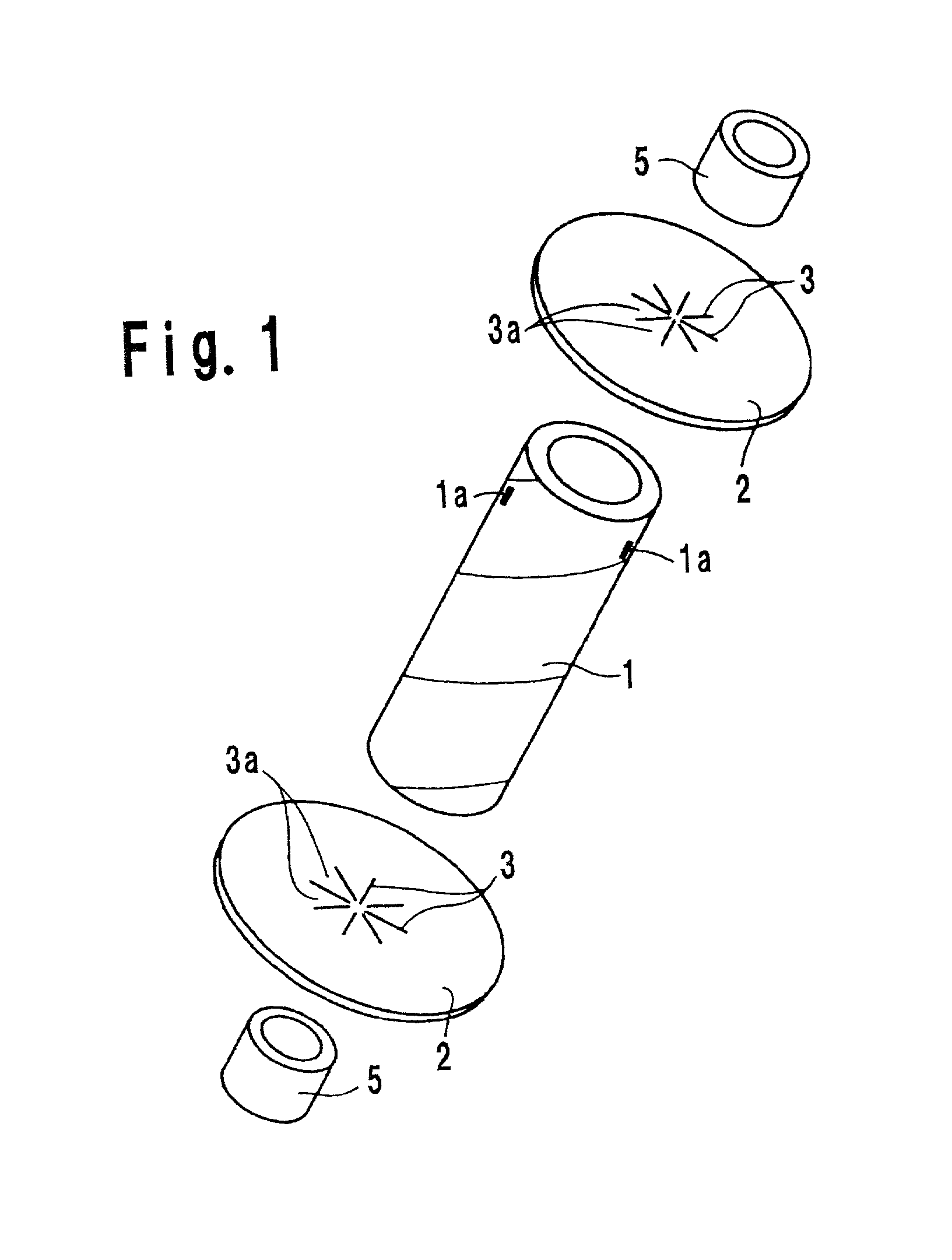

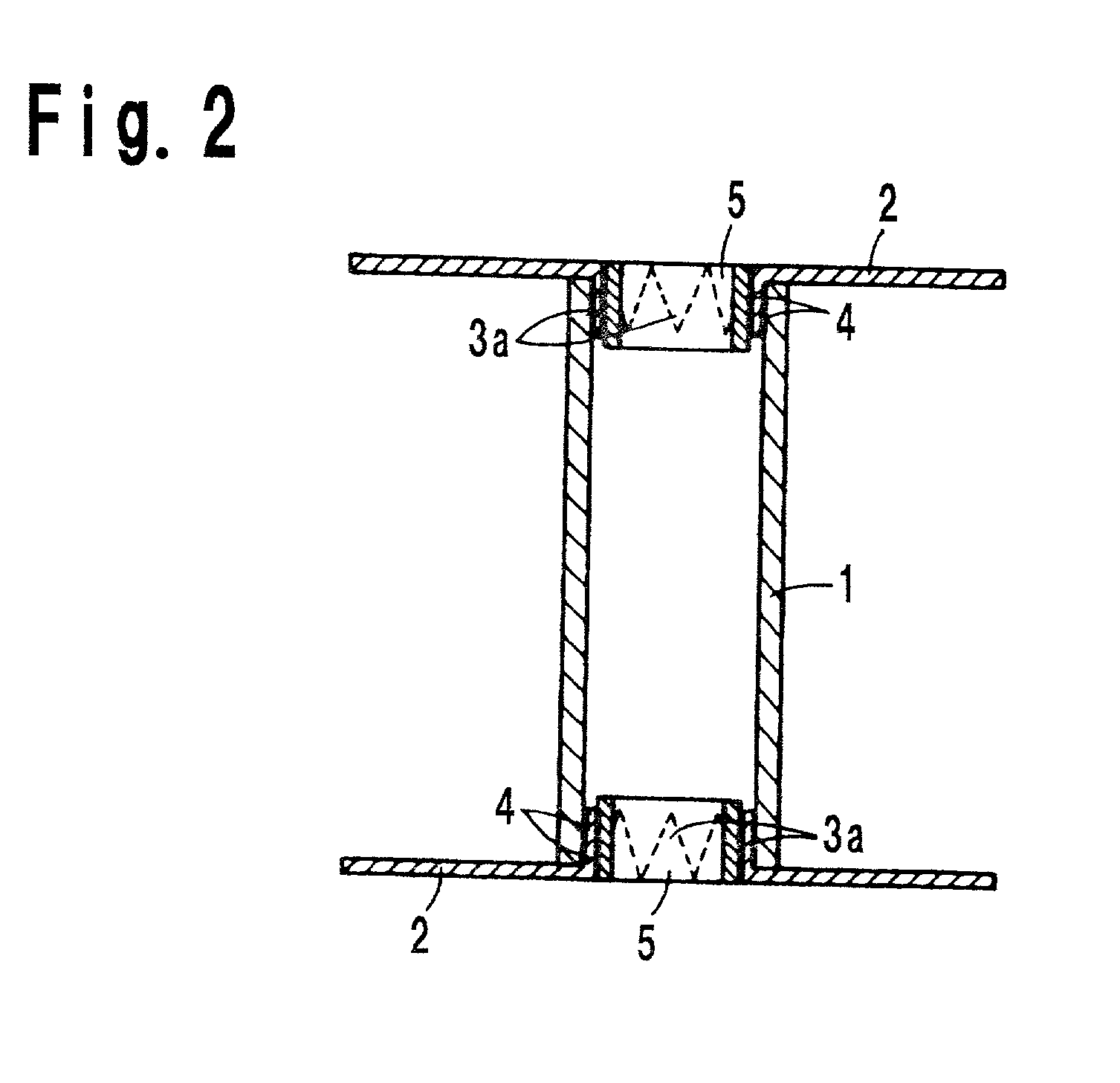

[0013] Embodiments of the present invention will be detailed hereunder with referring to FIGS. 1 and 2 as attached. A paper tube with a flange according to the present invention comprises a winding trunk outer tube 1 in a cylindrical shape, two flanges 2 in a disc-like shape and having cuts 3 extending radially from the central part, and two inner tubes 5 for pressing or tight-fitting in order to mount the flanges 2 onto the ends of the winding trunk outer tube 1, and all of these components being made of paper.

[0014] The winding trunk outer tube 1 consists of a cylindrical spiral-paper tube made of a strip of basic paper spiraled in multi-layers and adhered. The outer tube 1 has at a proper position a retaining bore la for an initial end of the object to be wound. Shapes of the retaining bore la may vary depending upon kinds of the objects to be wound.

[0015] The flange 2 is made of pasteboard or corrugated board having strength and thickness fully enough to bear rolling and may use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| cylindrical shape | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com