Processing of oxide superconductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

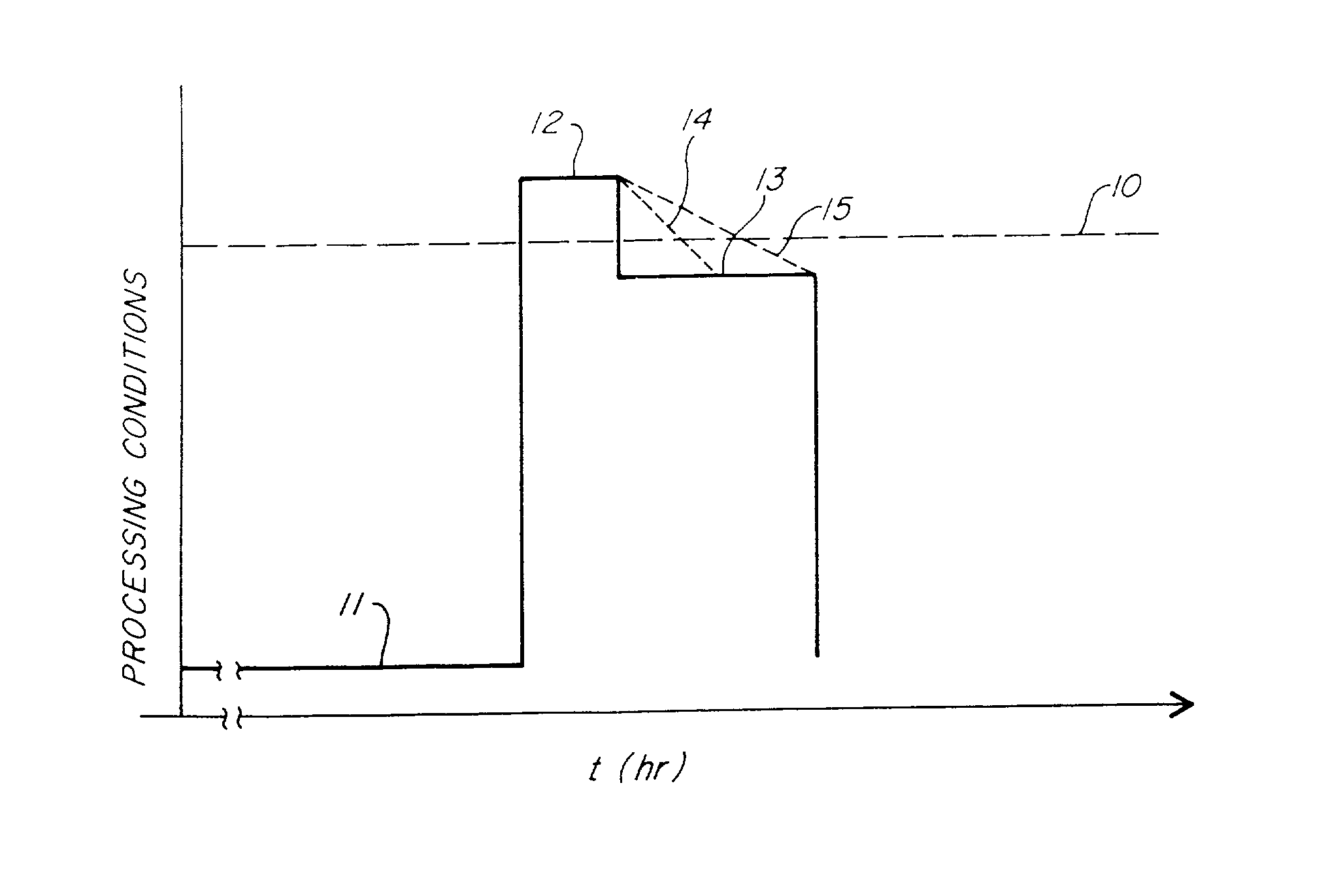

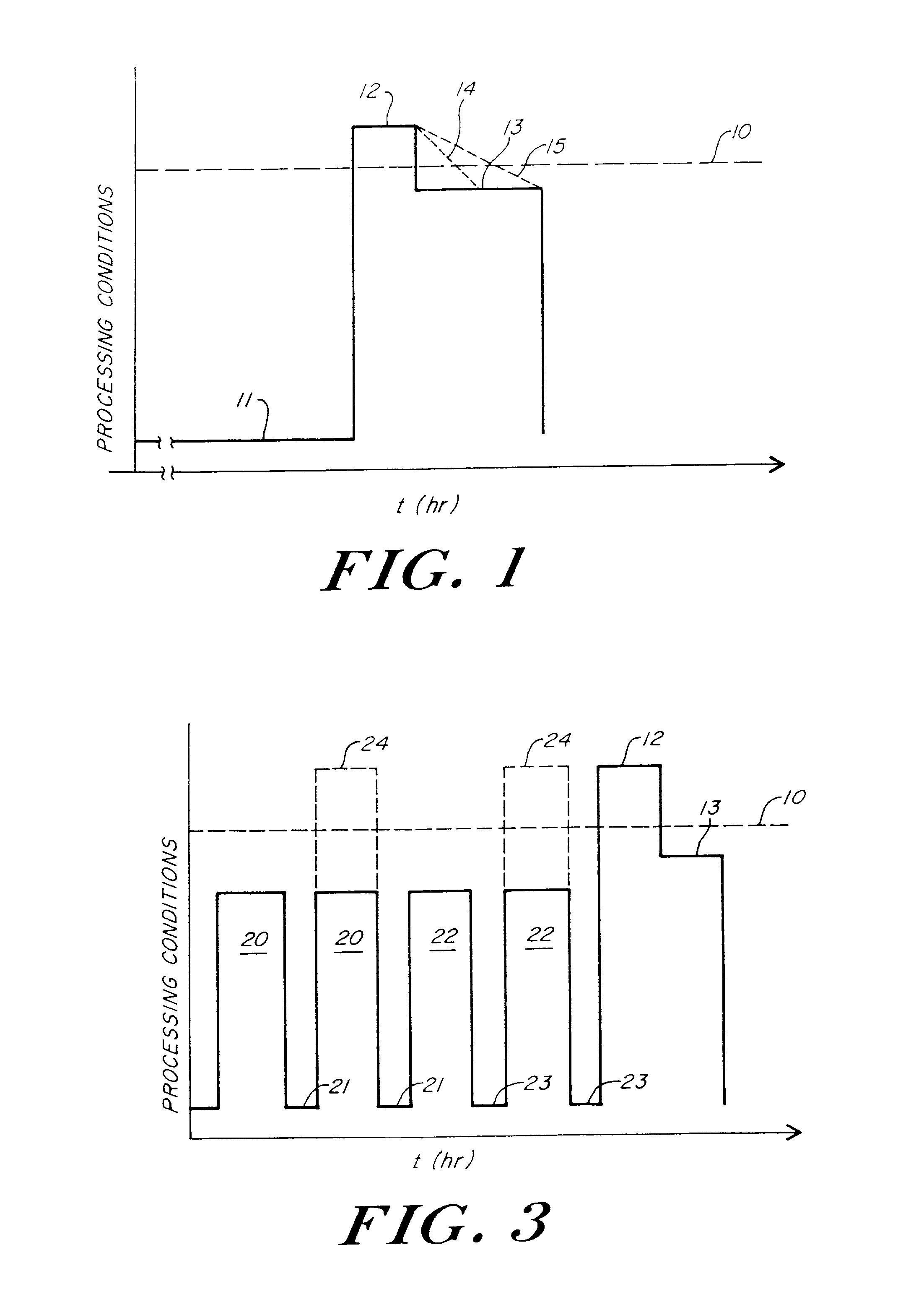

[0108] The following example compares the transport critical current characteristics of a samples treated with the two-step heat treatment of the present invention to those of conventionally processed samples.

[0109] Precursor powders were prepared from the solid state reaction of freeze-dried precursor of the appropriate metal nitrates having the nominal composition of 1.7:0.3:1.9:2.0:3.1 (Bi:Pb:Sr:Ca:Cu). Bi.sub.2O.sub.3, CaCO.sub.3, SrCO.sub.3, Pb.sub.3O.sub.4 and CuO powders could be equally used. After thoroughly mixing the powders in the appropriate ratio, a multistep treatment (typically, 3-4 steps) of calcination (800.degree. C..+-.10.degree. C., for a total of 15 h) and intermediate grinding was performed in order to remove residual carbon, homogenize the material and to generate the low T.sub.c BSCCO-2212 oxide superconductor phase. The powders were packed into silver sheaths having an inner diameter of 0.625" (1.5875 cm) and a length of 5.5" (13.97 cm) and a wall thickness...

example 2

[0114] This example demonstrates that silver alloys can be used in place of silver for the silver billet without detrimental effect on the electrical properties of the composite. A composite tape is prepared as described in Example 1; however, a silver alloy containing low levels of Mg and Ni was used to sheathe the oxide superconductor. The tape was processed as in Example 1 according to the method of the invention. The average I.sub.c (77K, 10 cm) was 7.68 A as compared to ca, 4.08 A for a conventional process.

example 3

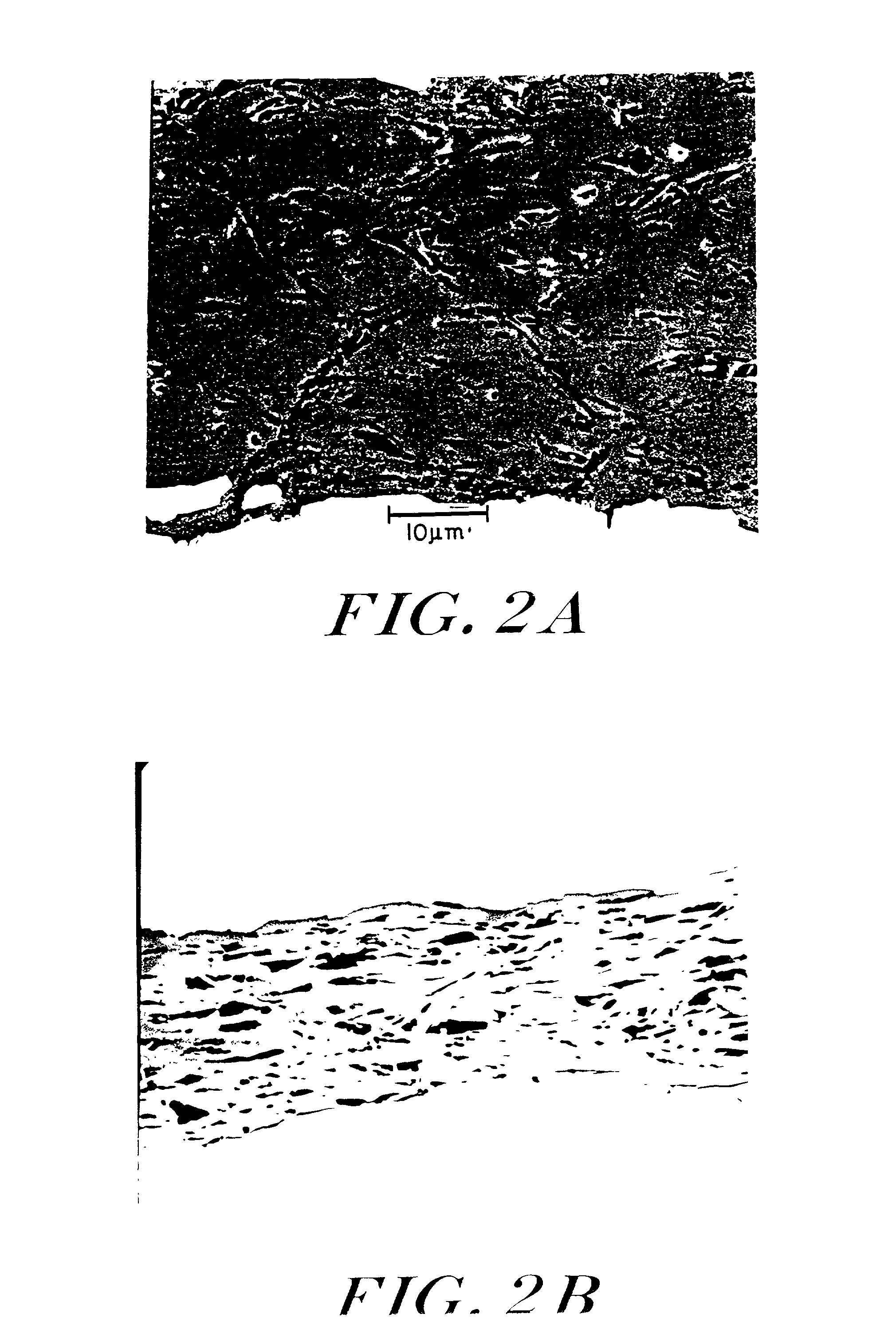

[0115] This example compares samples which have been pressed or rolled as the intermediate deformation.

[0116] Composite tapes were prepared as described in Example 1. A statistically designed experiment was performed using the following process parameters for the first anneal and final heat treatments.

2 two-step heat treatment first heat treatment high temperature low temperature T(.degree.C.) t(h) T(.degree.C.) t(h) T(.degree.C.) t(h) - 820 12 - 820 12 - 810 36 0 827 24 0 827 24 0 815 54 + 835 48 + 835 48 + 815 72

[0117] Up to sixty four statistically selected combinations of reaction conditions were run both with and without the two-step heat treatment of the invention. The intermediate deformation step between the first heat treatment and two-step heat treatment consisted of a pressing with 12% strain reduction.

[0118] Comparable statistically designed experiments were carried out for rolled samples with and without the two-step heat treatment of the invention. The intermediate def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com