Hydroconversion process for making lubricating oil basestocks

a technology conversion processes, which is applied in the field of lubricating oil basestocks, can solve the problems of unfavorable toxicity characteristics, low lubricating oil basestocks, and the fact that solvent refining alone produces basestocks with high saturates content, and achieves excellent toxicological properties, low volatility, and good oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

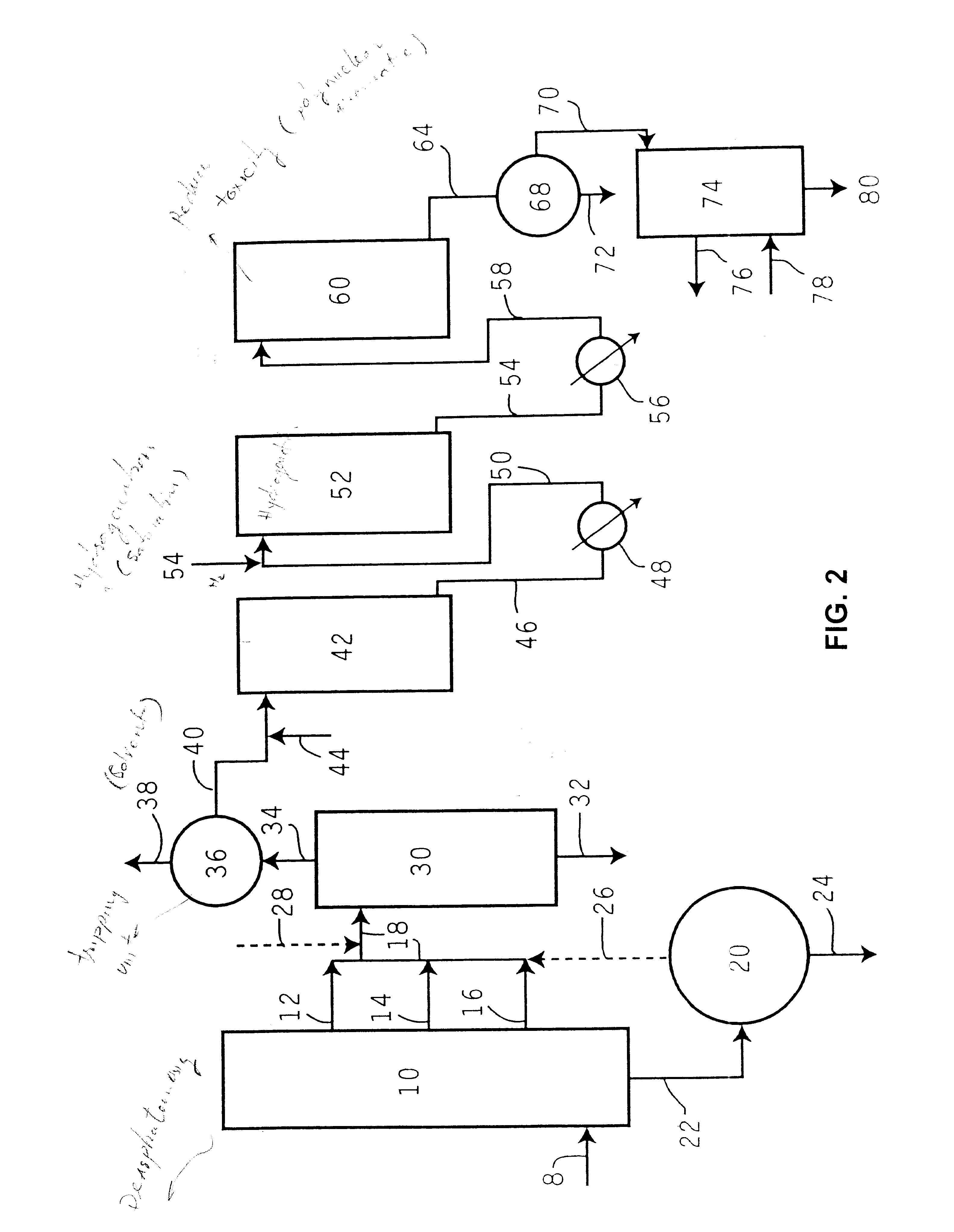

[0068] This example illustrates the functions of each reactor A, B and C. Reactors A and B affect VI though A is controlling. Each reactor can contribute to saturates, but Reactor B is primarily used to control saturates. Toxicity and color are controlled in reactor C.

1 TABLE 1 PRIMARY CONTROL Reactor A Reactor B Reactor C VI x Saturates x Toxicity x

example 2

[0069] This example illustrates the product quality of oils obtained from the process according to the invention. Reaction conditions and product quality data for start of run (SOR) and end of run (EOR) are summarized in Tables 2 and 3.

[0070] As can be seen from the data in Table 2 for the 250N feed stock, reactors A and B operate at conditions sufficient to achieve the desired viscosity index, then, with adjustment of the temperature of reactor C, it is possible to keep saturates above 90 wt. % for the entire run length without compromising toxicity (as indicated by DMSO screener result; see Example 6). A combination of higher temperature and lower space velocity in reactor C (even at end of run conditions in reactors A and B) produced even higher saturates, 96.2%. For a 100N feed stock, end-of-run product with greater than 90% saturates may be obtained with reactor C operating as low as 290 C. at 2.5 v / v / h (Table 3).

2 TABLE 2 SOR EOR EOR EOR Re- T LHSV T LHSV T LHSV T LHSV actor (...

example 3

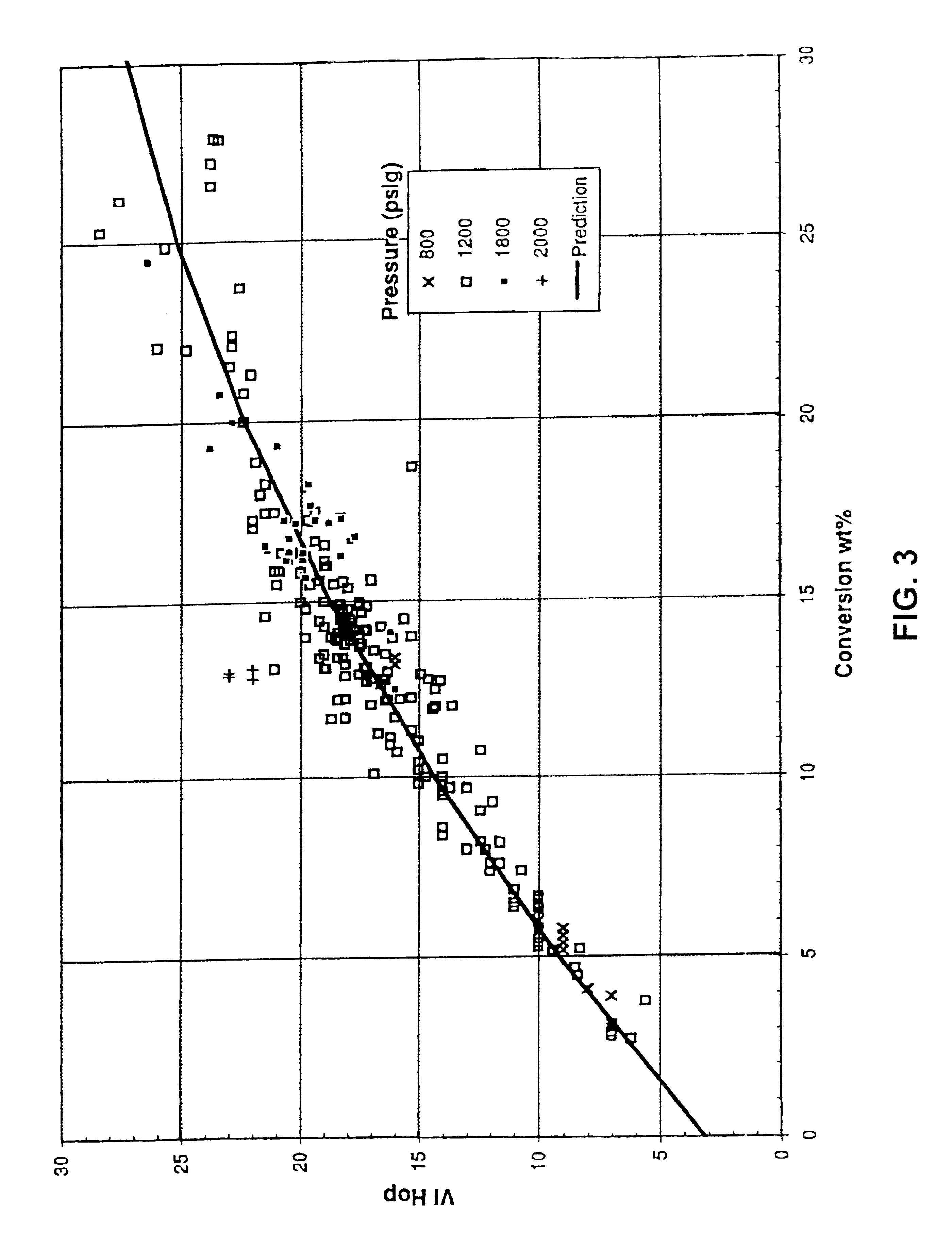

[0072] The effect of temperature and pressure on the concentration of saturates (dewaxed oil) at constant VI is shown in this example for processing the under extracted 250N raffinate feed. Dewaxed product saturates equilibrium plots (FIG. 5) were obtained at 600, 1200 and 1800 psig (4.24, 8.38 and 12.5 mPa) H2 pressure. Process conditions were 0.7 LHSV (reactor A+B) and 1200 to 2400 SCF / B (214 to 427 m.sup.3 / m.sup.3). Both reactors A and B were operating at the same temperature (in the range 350 to 415.degree. C.).

[0073] As can be seen from the figure it is not possible to achieve 90 wt. % saturates at 600 psig (4.14 mPa) hydrogen partial pressure. While in theory, one could reduce the temperature to reach the 90 wt. % target, the space velocity would be impracticably low. The minimum pressure to achieve the 90 wt. % at reasonable space velocities is about 1000 psig (7.0 mPa). Increasing the pressure increases the temperature range which may be used in the first two reactors (react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| hydrogen partial pressure | aaaaa | aaaaa |

| hydrogen partial pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com