One material, one piece spill-proof closure

a one-piece, spill-proof technology, applied in drinking vessels, household applications, table equipment, etc., can solve the problems of high cost of making multi-piece structures, inability to meet the needs of mass production methods or disposable applications, and inability to meet the needs of disposable markets, etc., to achieve the effect of reducing the cost of making such closures, and reducing the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

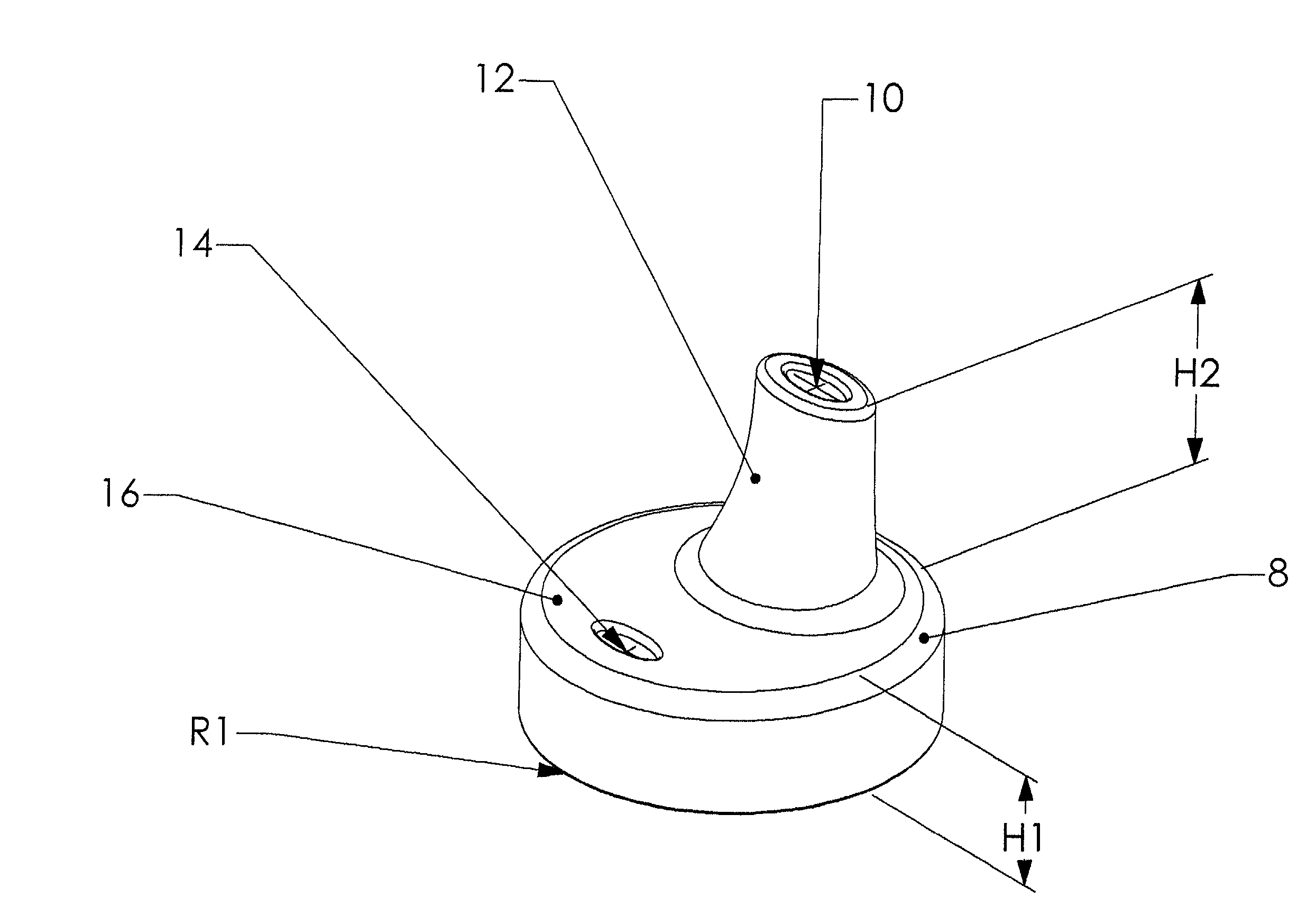

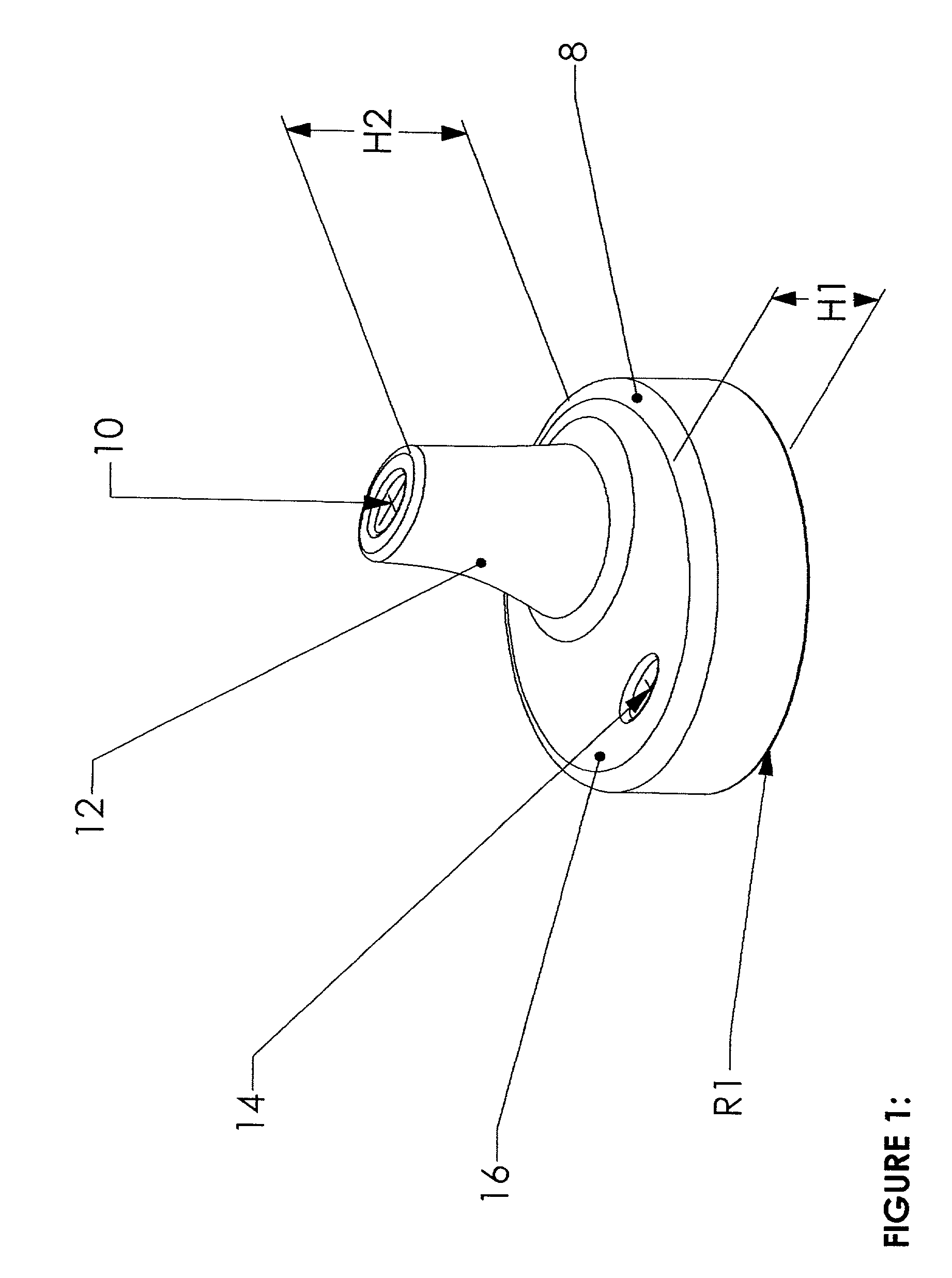

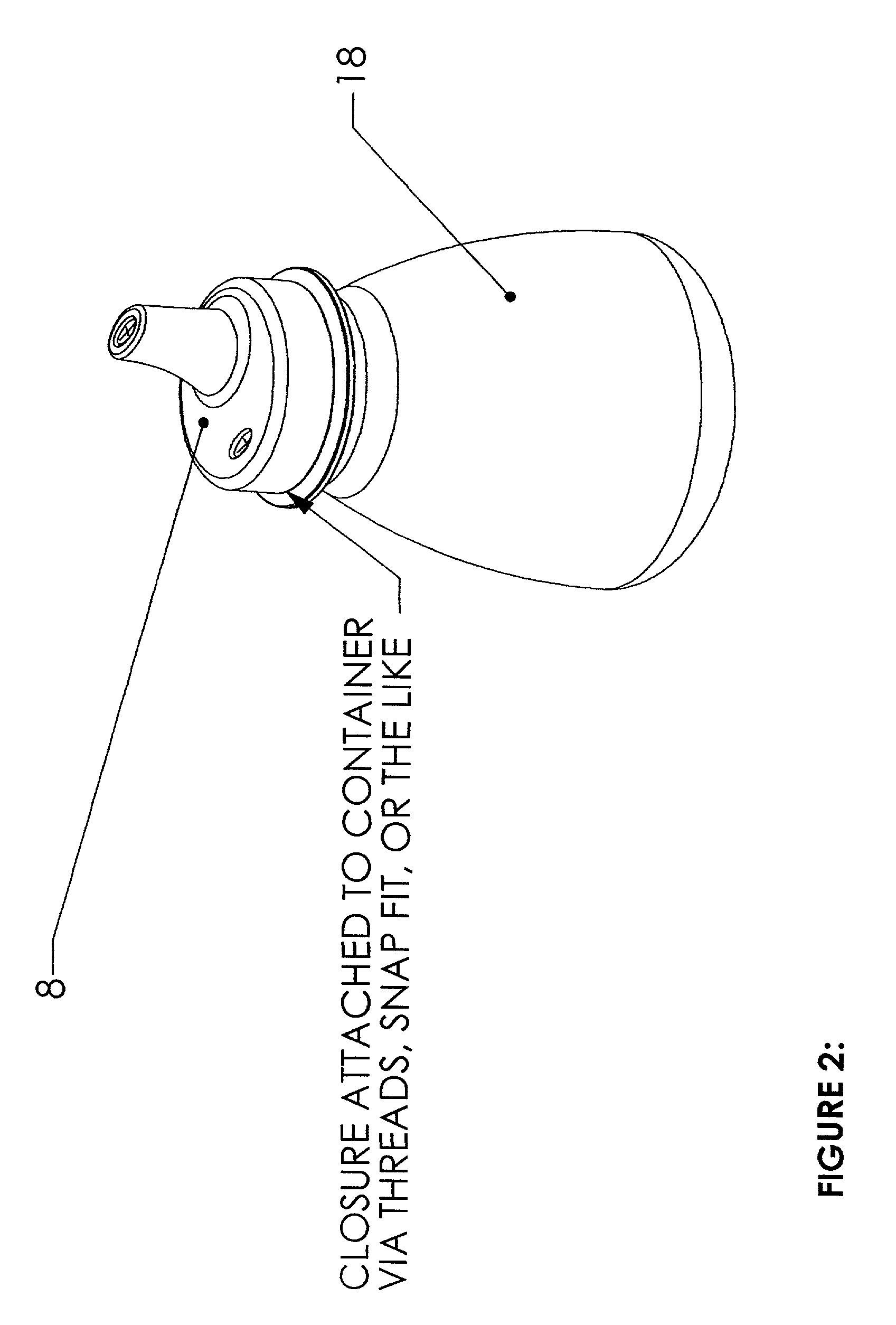

[0021] Generally, the preferred embodiment in accordance with the present invention is a spill-proof closure for a liquid container comprising a single component. The spill-proof closure is constructed from a single material in a single manufacturing operation. The container to which the spill-proof closure attaches can be made of any material known in the art for drinking containers. Examples of materials suitable for use as the liquid container include., but are not limited to, polyethylene, polypropylene. polyethylene terephthalate, polyethylene napthalate, polyvinyl chloride, nylon, ethylene vinyl alcohol, glass, aluminum. tin and combinations thereof. The container may be made by any means known in the art, such as blow molding, injection molding, extrusion molding or glass forming.

[0022] The present invention is suitable for any application or container, and it is particularly suitable for containers holding liquids, such as drinking containers. Often, drinking containers used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com