Methods of utilizing boiler blowdown for reducing NOX

a technology of boiler blowdown and nox, which is applied in the direction of water feed control, combustion types, furnaces, etc., can solve the problems of increasing the cost of boiler operation and lowering the boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

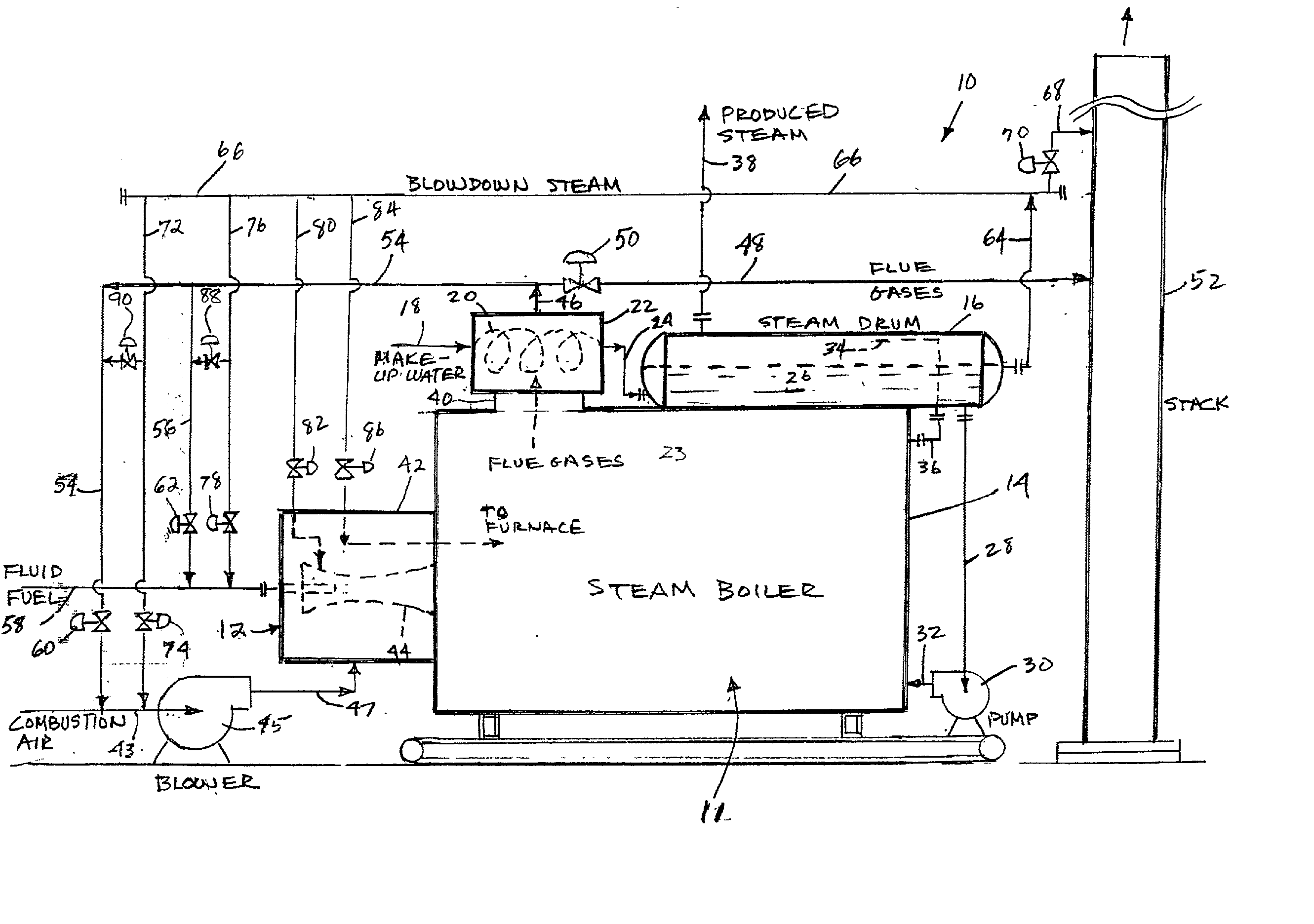

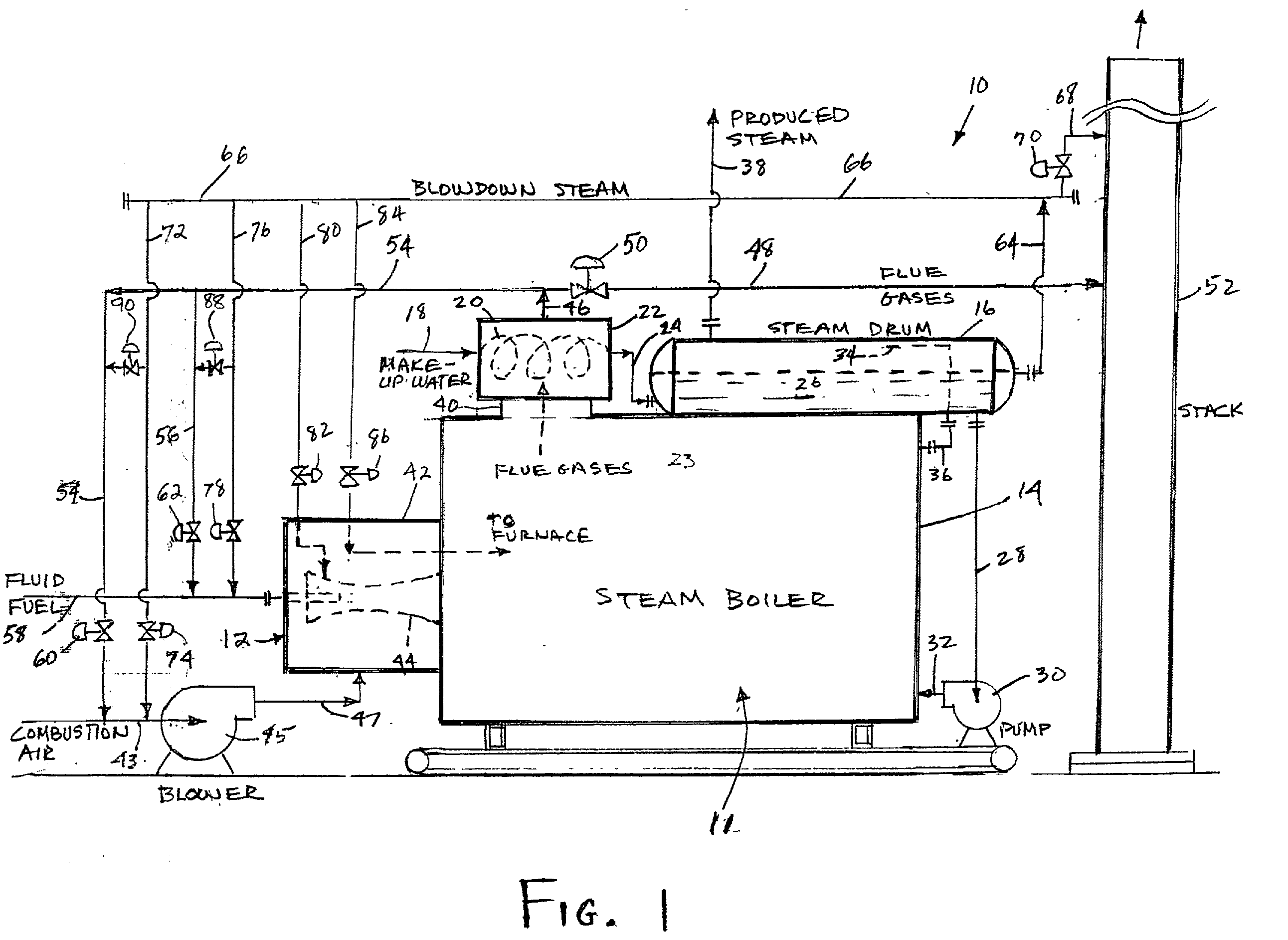

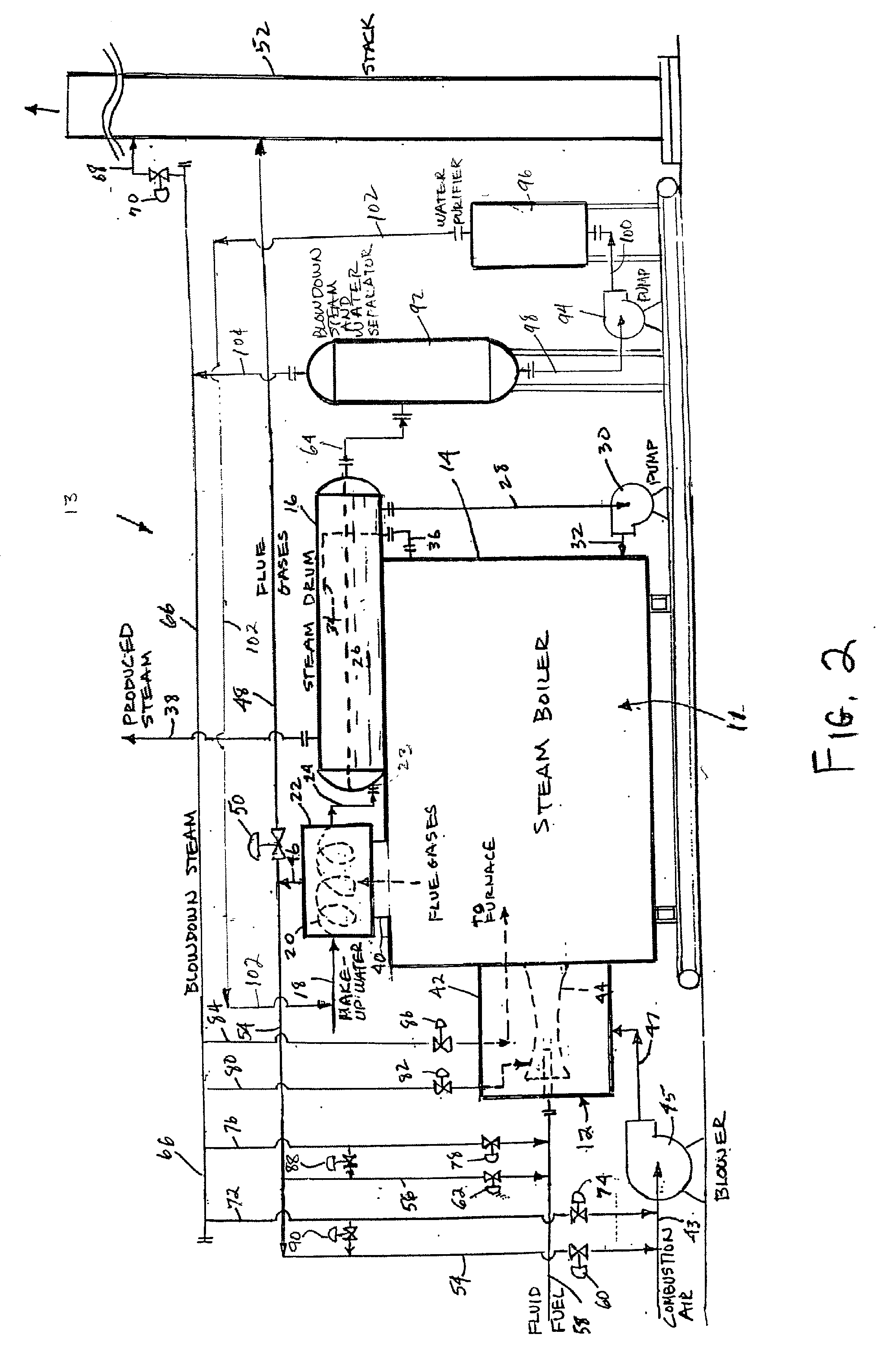

[0015] As mentioned above, steam boilers fired by fluid fuel and combustion air burners have included steam drums from which produced steam and blowdown steam are withdrawn. The blowdown steam withdrawn from the steam drum is required to maintain an appropriate dissolved solids content in the boiler water whereby adverse scale formation does not result. The blowdown steam is either vented to the atmosphere or used for preheating the boiler make-up water with the remaining steam being vented to the atmosphere. Typically, the substantially wasted blowdown steam comprises from about 1.5 to about 5% of the total steam produced by the steam boiler.

[0016] In accordance with the present invention, the heretofore wasted blowdown steam is at least partially utilized for reducing the NO.sub.x emissions produced by the boiler. That is, the blowdown steam is combined with the boiler fluid fuel and / or the combustion air and / or injected into the flame produced by the burner and / or injected into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com