Boiler blow-down water comprehensive utilization device

A boiler blowdown and blowdown expansion technology, which is applied in boiler cleaning devices, indirect carbon dioxide emission reduction, combustion methods, etc., can solve problems such as heat pollution and energy waste, and achieve the effects of avoiding pollution, improving efficiency, and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

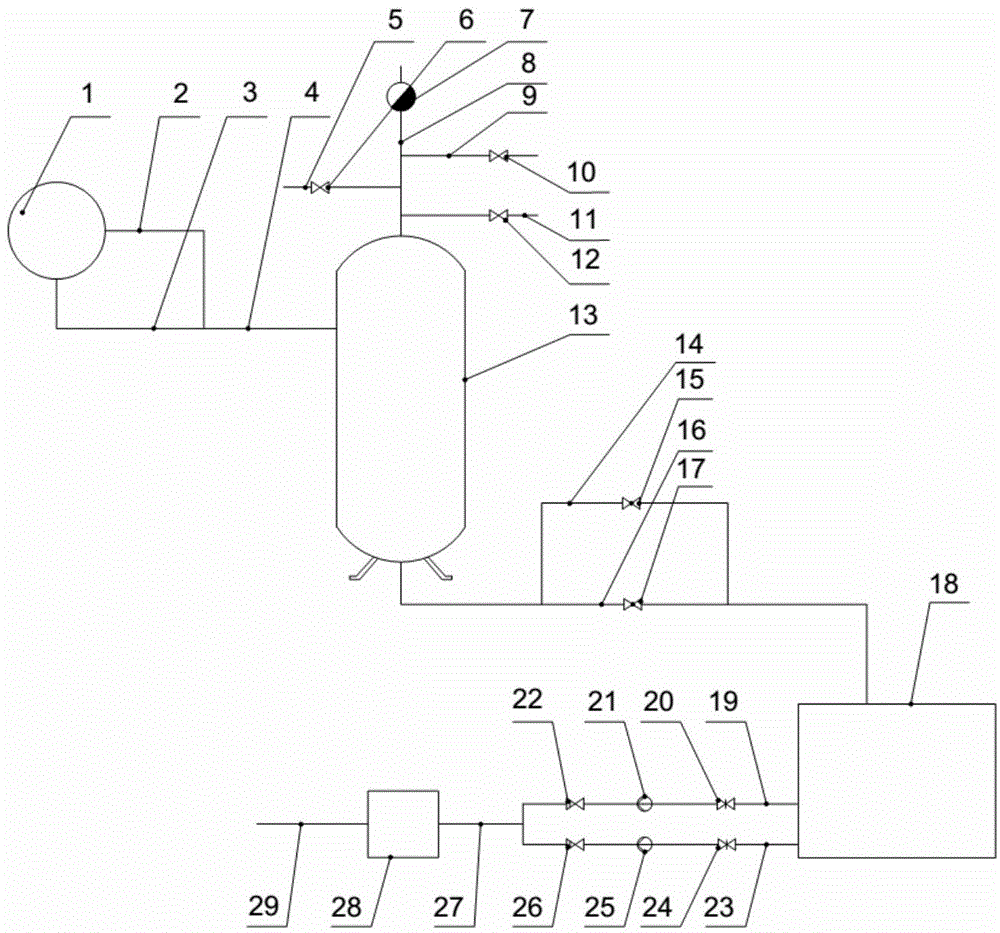

[0010] Such as figure 1 As shown, a boiler sewage comprehensive utilization device includes a boiler 1, a first pipeline 2, a second pipeline 3, a third pipeline 4, a fourth pipeline 5, a first regulating valve 6, a steam trap 7, and a fifth pipeline 8 , the sixth pipeline 9, the second regulating valve 10, the seventh pipeline 11, the third regulating valve 12, the sewage expansion vessel 13, the eighth pipeline 14, the first ball valve 15, the ninth pipeline 16, the second ball valve 17, the cooling pool 18. Tenth pipeline 19, first gate valve 20, first pump 21, first check valve 22, eleventh pipeline 23, second gate valve 24, second pump 25, second check valve 26, twelfth Pipeline 27, raw water filter tank 28 and the thirteenth pipeline 29.

[0011] One end of the first pipeline 2 is connected to the boiler 1 , and the other end is connected to the third pipeline 4 , which is used as a continuous sewage discharge pipe and mainly discharges unqualified water to the sewage e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com