Boiler blow-off wastewater recovery treatment equipment

A technology for wastewater recovery and boiler blowdown, which is applied in water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of heat exchanger body damage and steam operating pressure rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

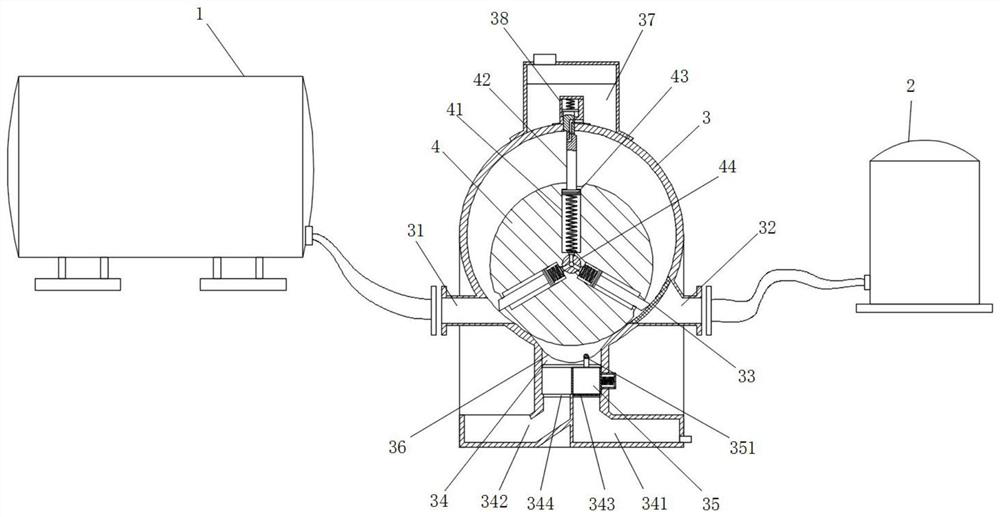

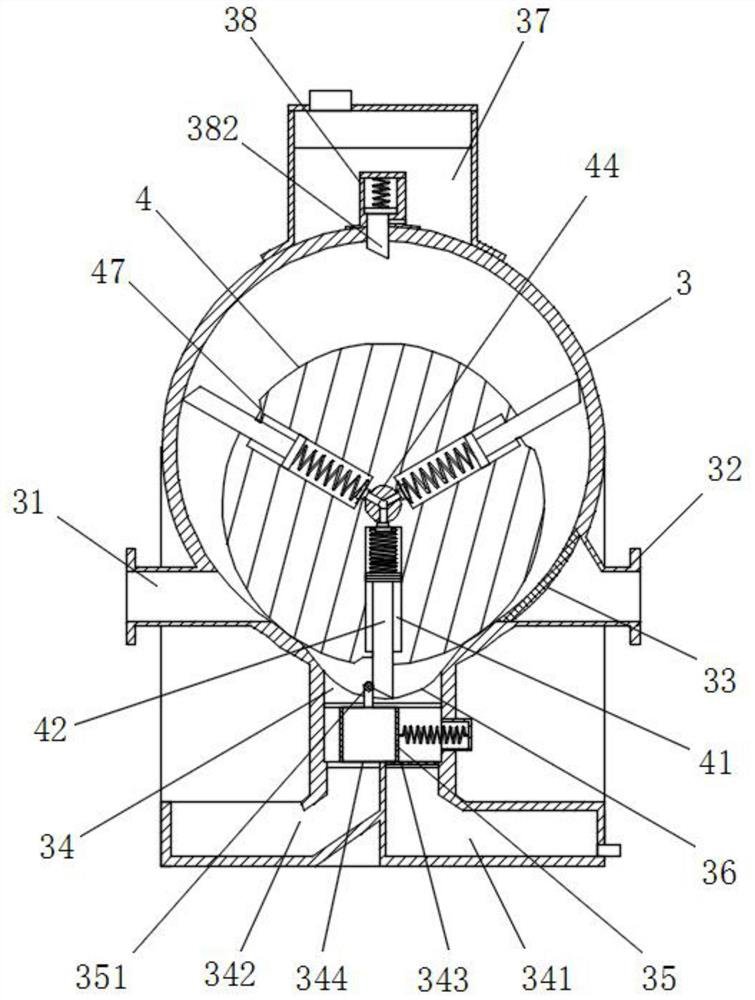

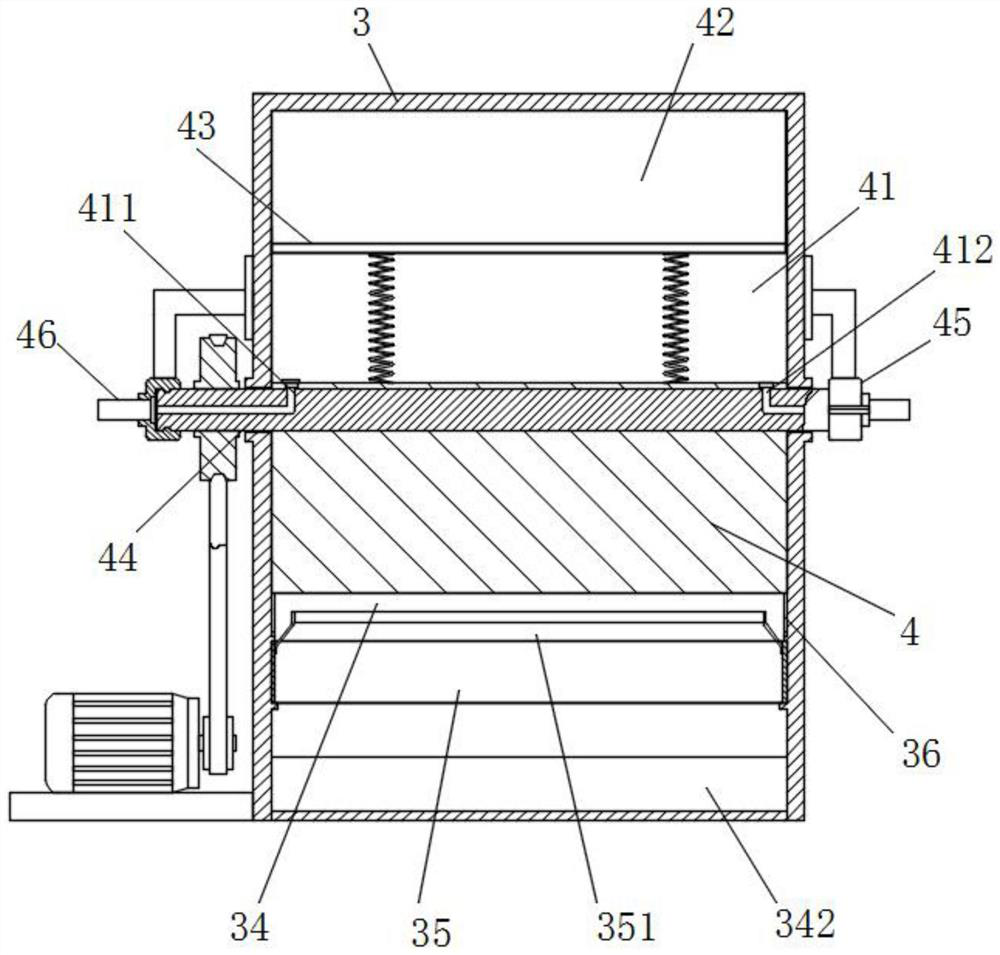

[0029] The present invention provides such as Figure 1-5The shown boiler blowdown waste water recycling and treatment equipment includes a boiler discharge system 1 and a regular blowdown expansion vessel 2. The boiler discharge system 1 is provided with a continuous blowdown blowdown vessel, and the high-temperature and high-pressure boiler blowdown water is first discharged into the continuous blowdown blowdown vessel. , and then discharged into the regular sewage expansion vessel 2 by the continuous blowdown expansion vessel, and the blowdown water flashes in the regular blowdown expansion vessel 2 to generate steam. The scheme of conventional recovery is to exchange heat with water in the newly-established steam-water heat exchanger with the steam generated by the expansion vessel for regular sewage discharge, and install a heat exchange filter device on the pipeline from the boiler discharge system 1 to the expansion vessel 2 for regular sewage discharge , the heat excha...

Embodiment 2

[0036] Such as Figure 1-3 The shown boiler blowdown waste water recycling and treatment equipment includes a boiler discharge system 1 and a regular blowdown expansion vessel 2. The boiler discharge system 1 is provided with a continuous blowdown blowdown vessel, and the high-temperature and high-pressure boiler blowdown water is first discharged into the continuous blowdown blowdown vessel. , and then discharged into the regular sewage expansion vessel 2 by the continuous blowdown expansion vessel, and the blowdown water flashes in the regular blowdown expansion vessel 2 to generate steam. The scheme of conventional recovery is to exchange heat with water in the newly-established steam-water heat exchanger with the steam generated by the expansion vessel for regular sewage discharge, and install a heat exchange filter device on the pipeline from the boiler discharge system 1 to the expansion vessel 2 for regular sewage discharge , the heat exchange filtering device includes ...

Embodiment 3

[0041] Such as figure 1 , 2 A boiler blowdown waste water recovery treatment equipment shown in and 4, comprising a boiler discharge system 1 and a regular blowdown expansion vessel 2, the boiler discharge system 1 is provided with a continuous blowdown blowdown vessel, and the high temperature and high pressure boiler blowdown water is first discharged to the continuous blowdown blowdown expansion vessel In the device, then the continuous sewage expansion vessel is discharged into the regular sewage expansion vessel 2, and the sewage is flashed in the regular sewage expansion vessel 2 to generate steam. The scheme of conventional recovery is to exchange heat with water in the newly-established steam-water heat exchanger with the steam generated by the expansion vessel for regular sewage discharge, and install a heat exchange filter device on the pipeline from the boiler discharge system 1 to the expansion vessel 2 for regular sewage discharge , the heat exchange filtering de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com