Grinding tool for grinding buttons of a rock drill bit, a grinding spindle and method for mounting the grinding cup on a grinding spindle

a drilling bit and button technology, which is applied in the direction of grinding machines, boring/drilling apparatus, grinding teeth, etc., can solve the problems of abrasive grinding surface of wear parts of such grinding cups, complicating the design of grinding tools, etc., and achieves the effect of quickly mounting or dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

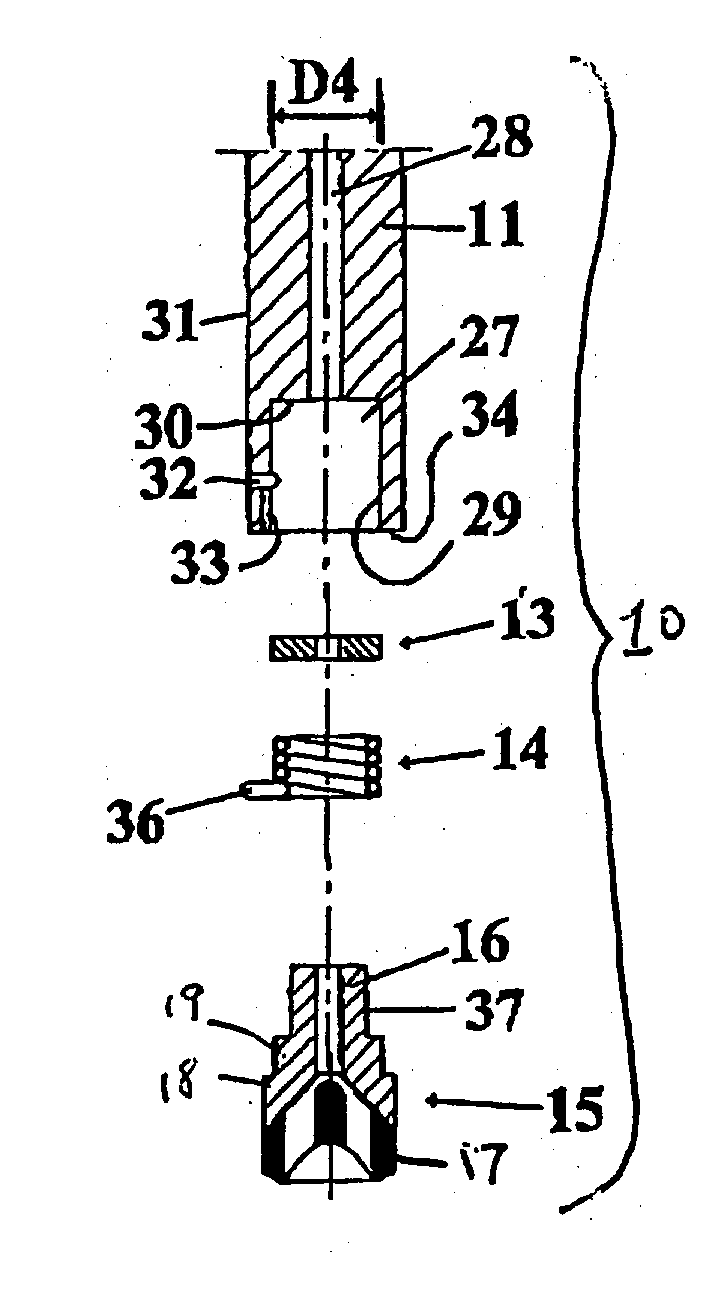

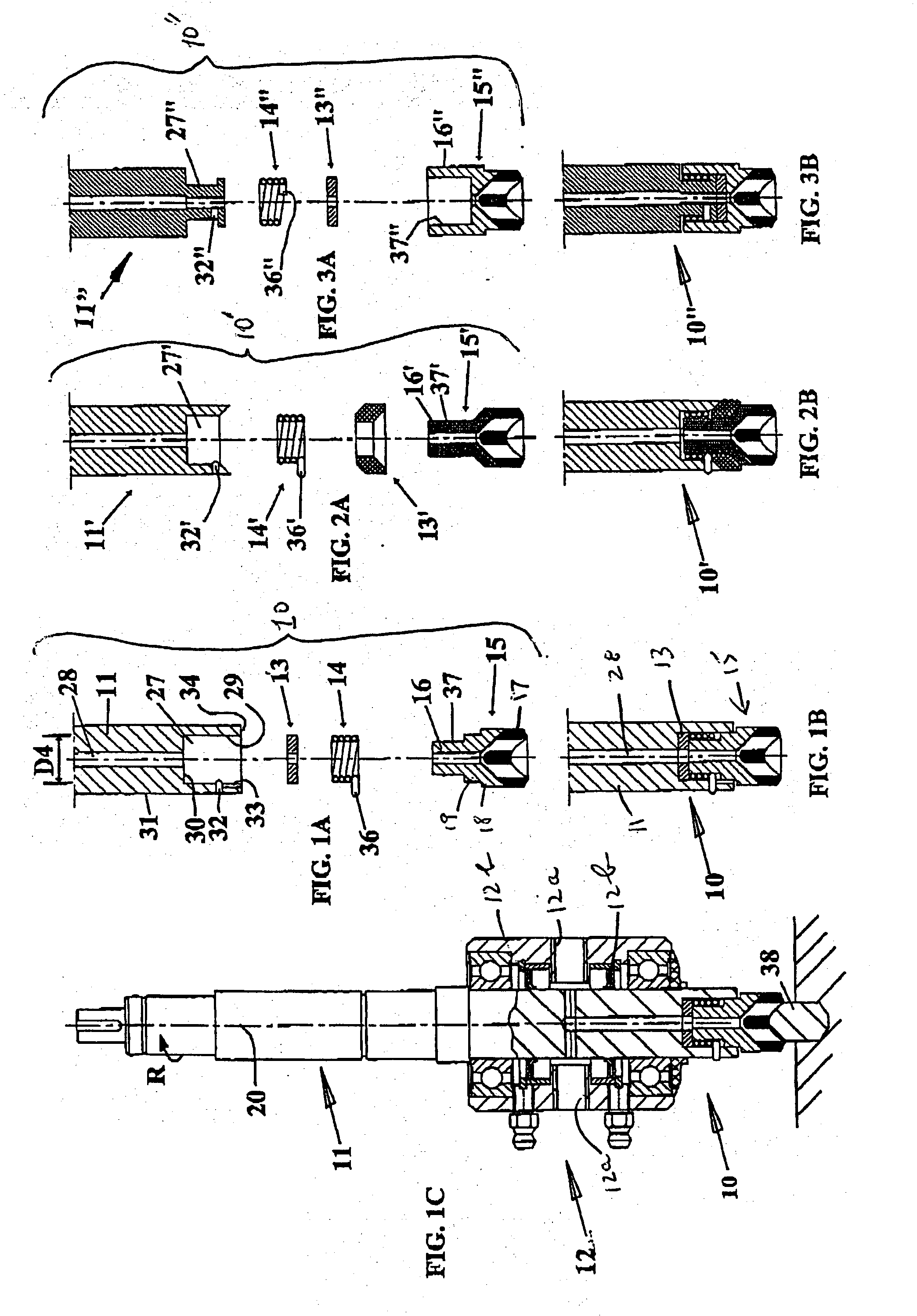

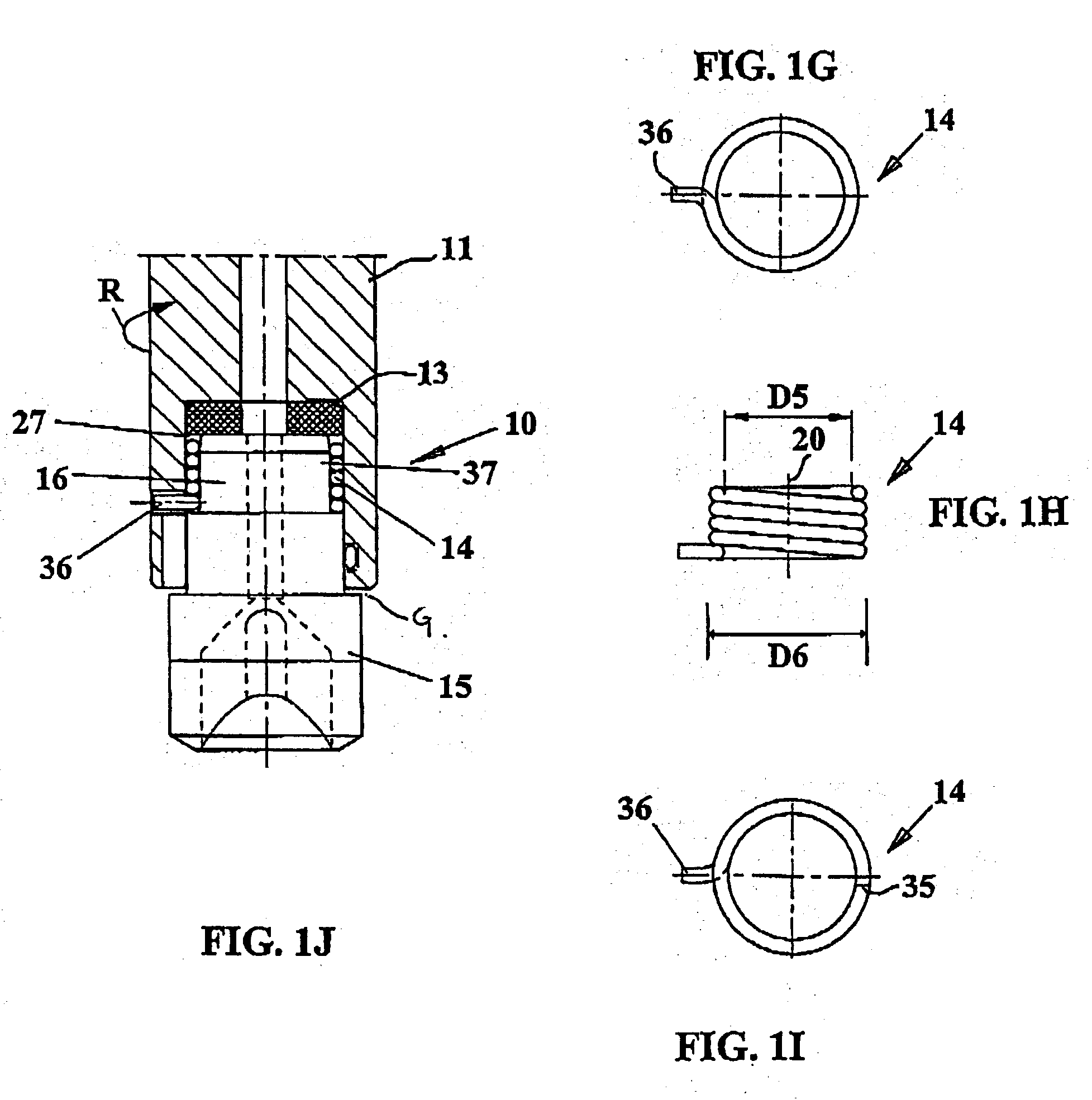

[0032] A first embodiment of a grinding tool 10 according to the present invention for grinding buttons of a rock drill bit is described hereinafter with reference to FIGS. 1A-1J. The tool comprises a grinding spindle 11, a vibration-damping means 13, a mounting means or a spring 14 and a grinding cup 15. In FIG. 1C the tool 10 is shown as mounted to a swivel or flushing head 12 to form a grinding assembly.

[0033] The upper end of the grinding spindle 11 is intended to be rotatably mounted in a grinding head, not shown, of the type shown and described in EP-B-734,306, which hereby is incorporated by reference into the description. The grinding head is thus connected to a power source such as an electric motor and can be vertically displaced, i.e. downwardly and upwardly. The grinding head comprises an external housing (not shown) which is stationary. The grinding spindle 11 is rotatably journalled in a boring of the spindle house by means of roller bearings that are spaced apart axia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com