Method and apparatus for including article identification in an article handling device

a technology of article identification and handling device, which is applied in the direction of de-stacking articles, article separation, instruments, etc., can solve the problems of poor reliability, inability to prevent the dispensing of incorrect products, and their use in tight confines, such as article vending machines, to achieve simple, accurate and reliable construction and operation, and improve the speed and accuracy of the article handling operation. , the effect of preventing any damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

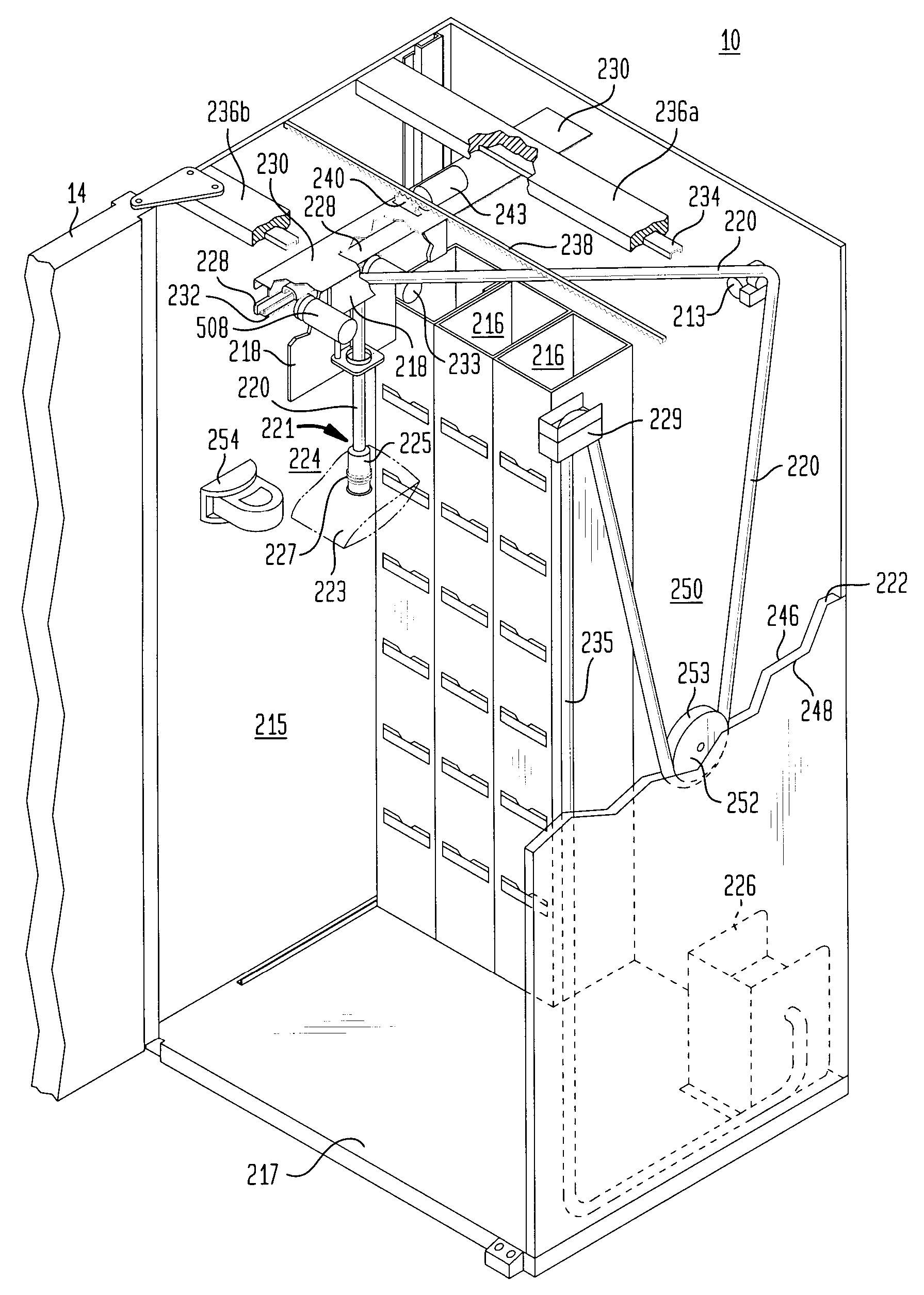

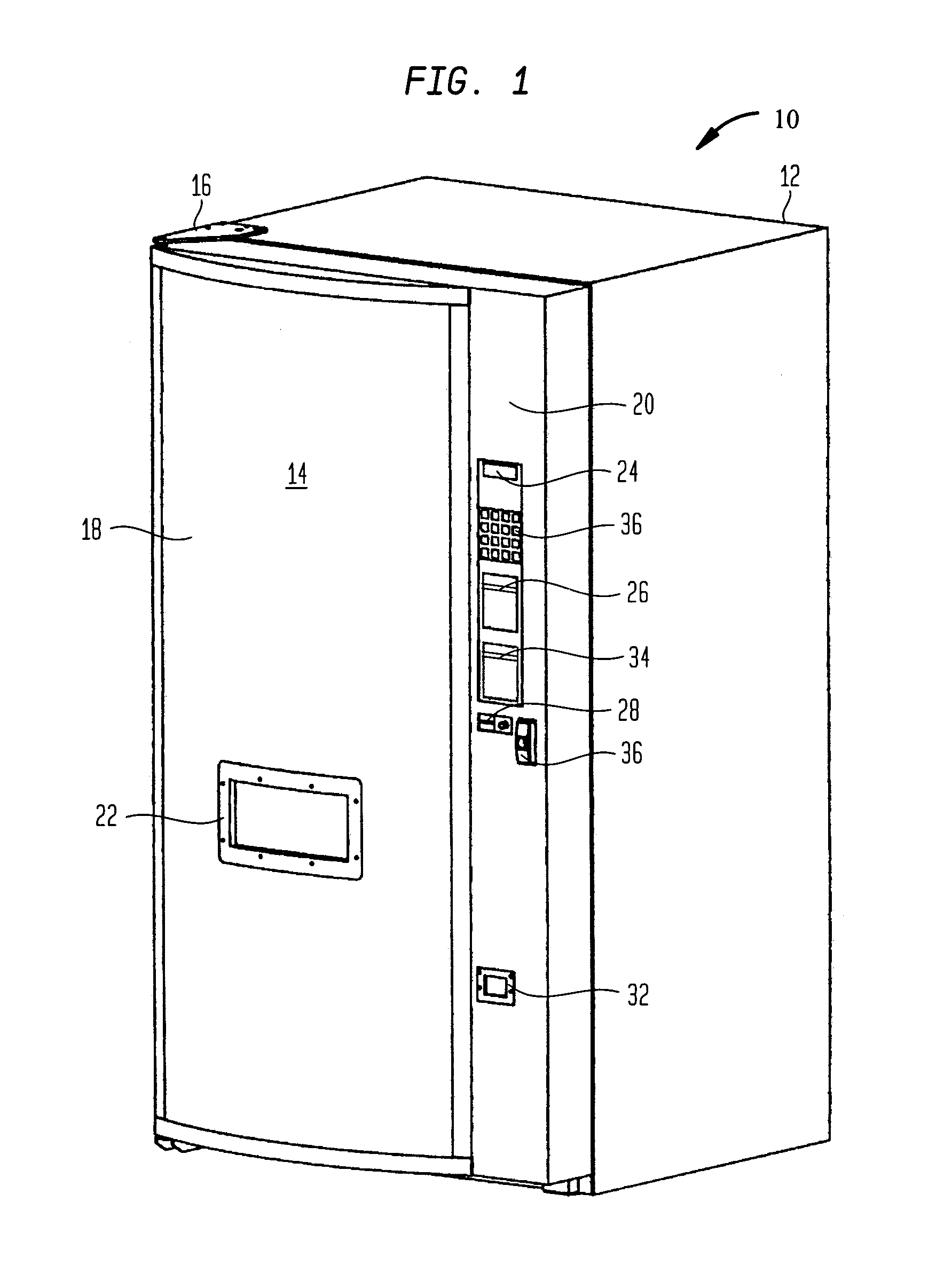

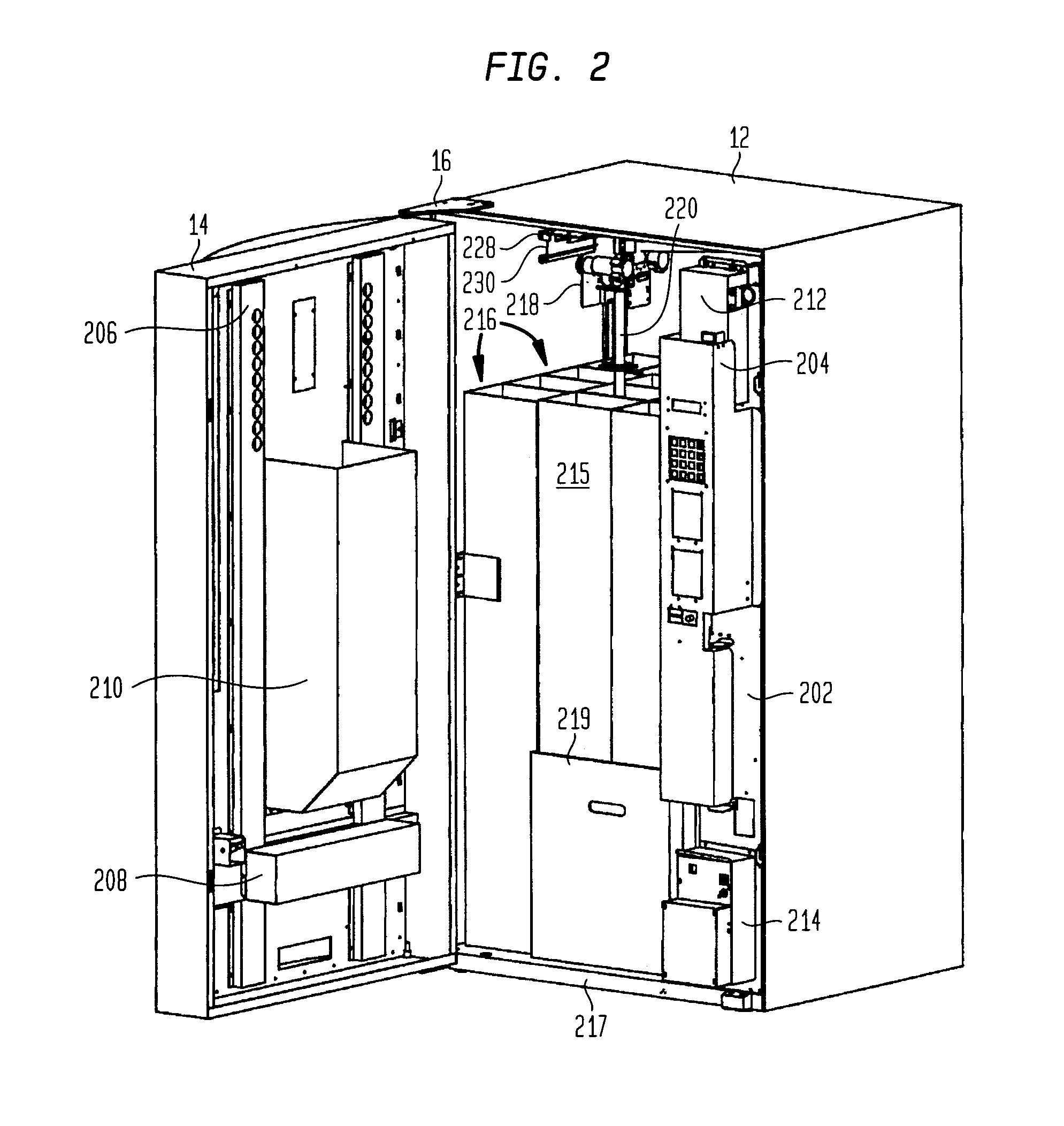

[0021] FIG. 1 illustrates an environment for the invention described herein, in the form of an article dispenser, such as a point-of-sale (POS) dispenser. Although throughout the following description, reference is made to implementation of the invention in a vending machine environment, it is intended that the term "vending machine", and in fact the environment for the present invention, include more general purpose article handling, retrieval and / or dispensing apparatus, as well as POS equipment. Such equipment, if embodied as a portable device may comprise and be about the size of a traditional vending machine or as large as a tractor-pulled trailer, and if embodied as a non-portable device may comprise and be embodied as an automated dispensing room or an area located in a permanent structure, such as in a building (aboveground or underground, and with or without interior walls or an enclosing cabinet). Furthermore, it is intended that the term "articles"or "products" include in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com