Well jet device

a jet pump and well technology, applied in the direction of jet pumps, non-positive displacement pumps, borehole/well accessories, etc., can solve the problems of reducing the strength of the unit, lowering the capacity of the jet pump, and the diameter of the passage for supplying the pumped out medium cannot be taken arbitrarily, so as to improve the reliability of the well jet unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

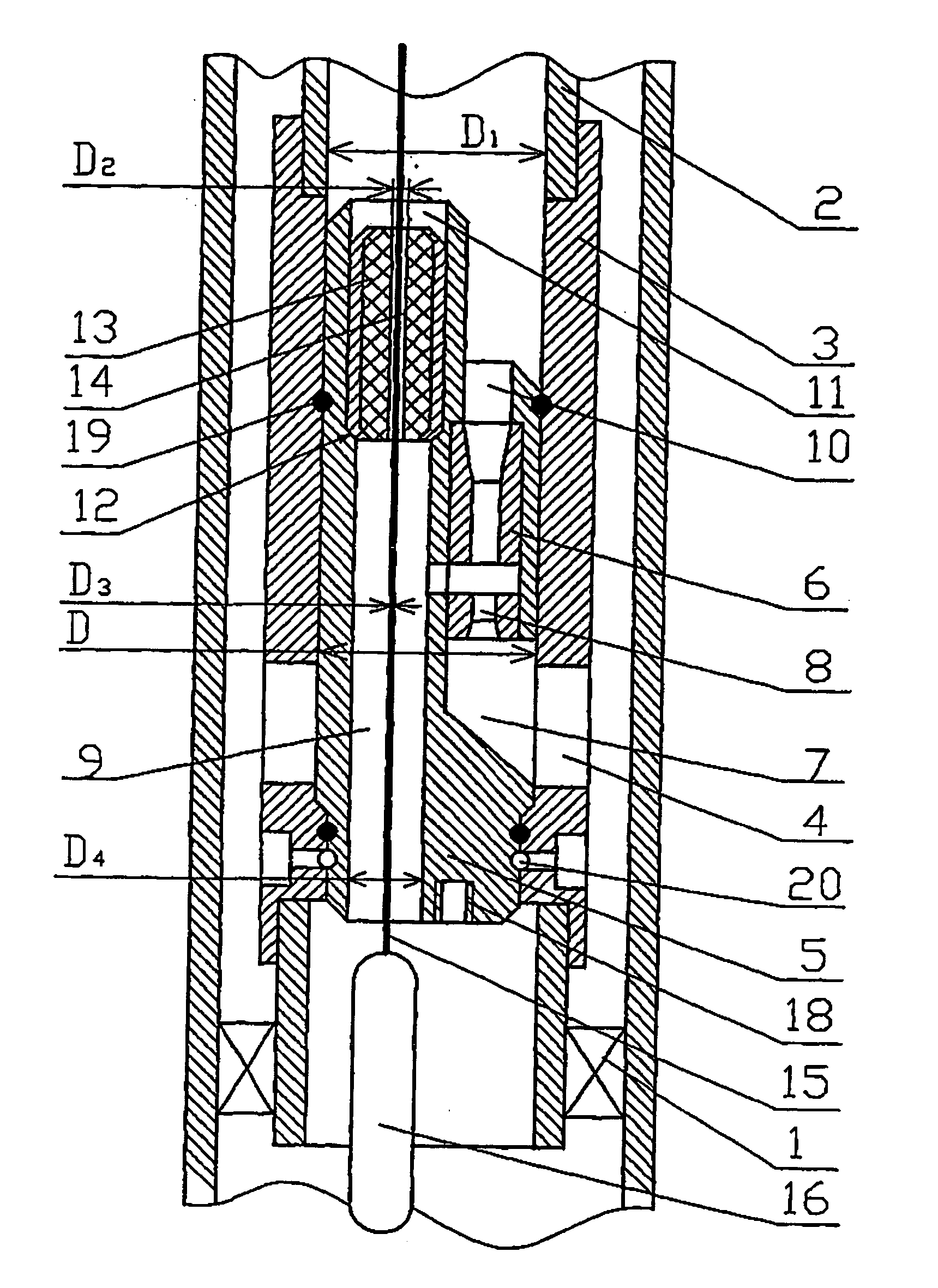

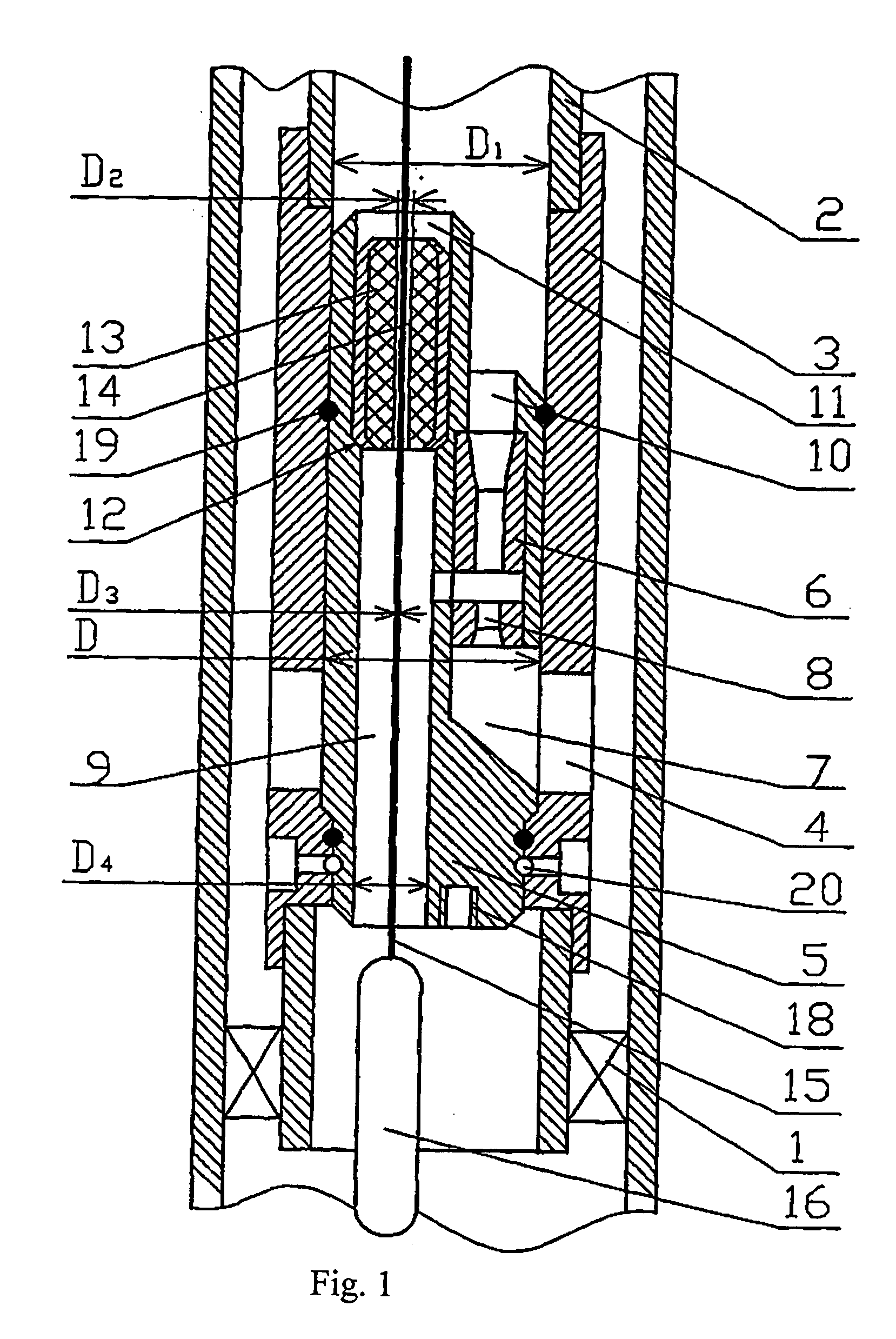

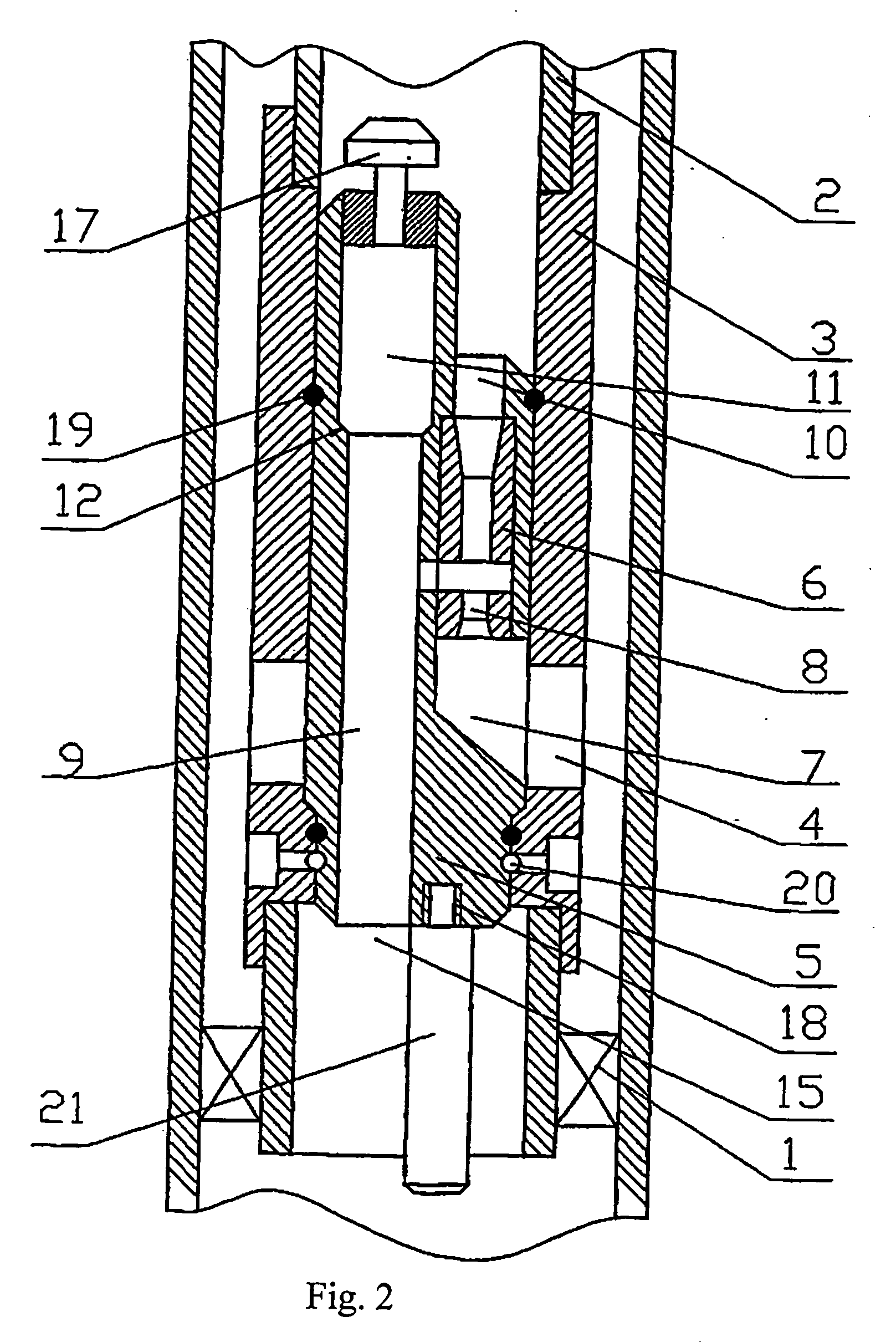

[0012] The proposed well jet unit comprises a packer 1, a piping string 2, having a support 3 wherein drain ports 4 are made and onto which a jet pump 6 with its housing 5 is installed, the said housing 5 comprises: a passage 7 in communication with drain ports 4 for supplying an active medium to the nozzle 8 of the jet pump 6 from the space surrounding the piping string 2, a passage 9 for supplying the medium pumped out of the well to the jet pump 6 and a passage 10 for removing a medium mixture from the jet pump 6 into the inner cavity of the piping string 2 above the jet pump 6, and in the housing 5 above the passage 9 for supplying the pumped out medium a through passage 11, being in communication with the passage 9 and being made with a mounting face 12 for installing a sealing assembly 13, and the sealing assembly 13 comprises a through passage 14 with the possibility of leading, through it and the passage 9 for supplying the pumped out medium, a cable 15 for the purpose of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com