Construction equipment

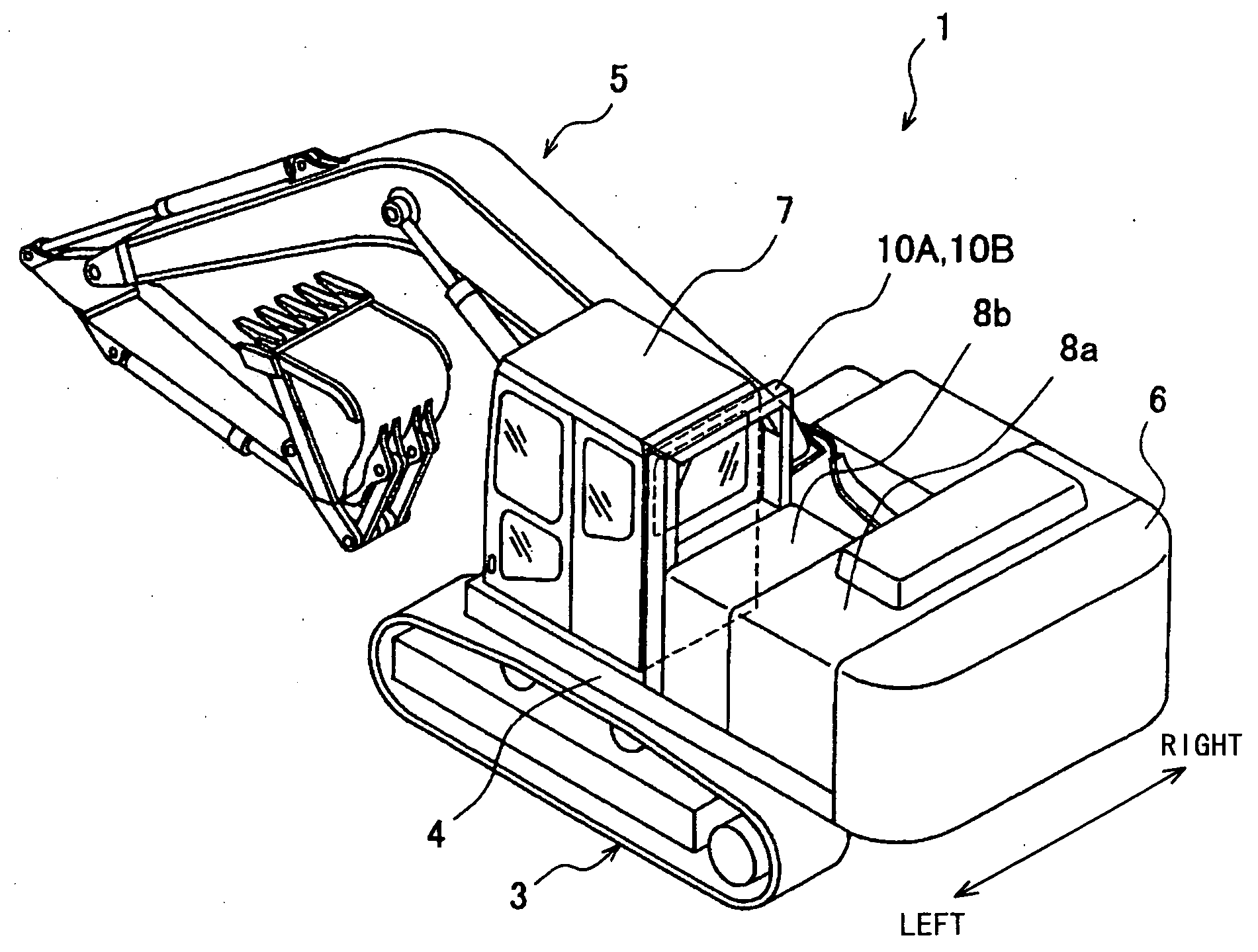

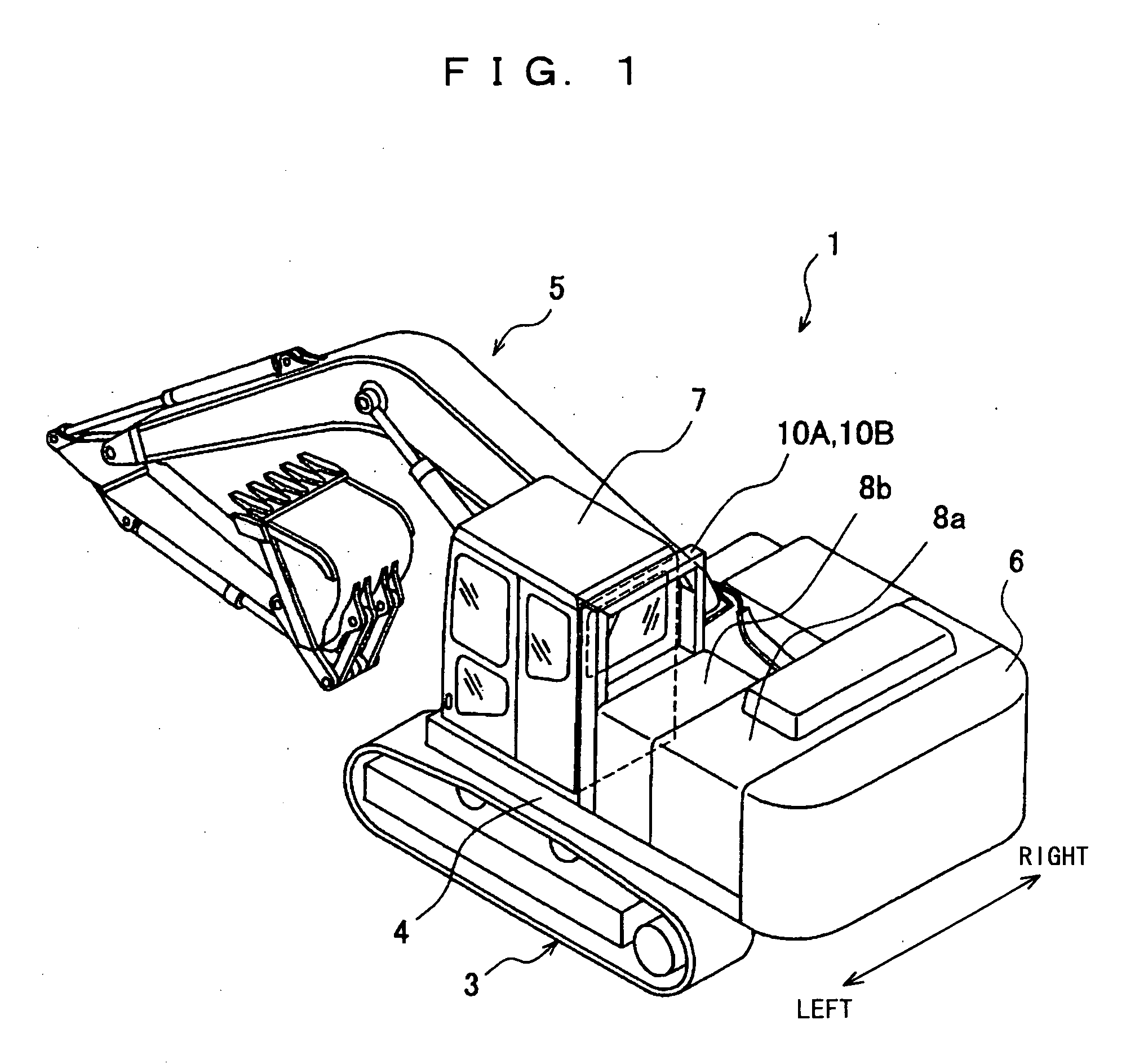

a construction equipment and equipment technology, applied in the direction of constructions, soil shifting machines/dredgers, etc., can solve the problems of reduced driving performance of the vehicle, increased vehicle weight, reduced visibility to the front, above and to the rear of the operator's cab, etc., to facilitate attaching and detaching operations, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0031] According to a constitution of the first embodiment, the following operation and effects are obtained.

[0032] (1) When the hydraulic excavator 1 rolls over, the operator's cab protection member 11 of the portal frame 10A and the working machine 5 is in contact with the ground, whereby the hydraulic excavator 1 is supported by the portal frame 10A and the working machine 5, and therefore deformation of the operator's cab 7 which is located between the portal frame 10A and the working machine 5 is prevented or restrained. As a result, the operator space inside the operator's cab 7 is secured.

[0033] (2) At this time, the portal frame 10A is placed in close vicinity to the rear surface of the operator's cab 7 to place the operator's cab protection member 11. As a result, the strong operator's cab protection frame 10A can be placed easily in small to large construction equipment.

[0034] (3) The operator's cab protection frame 10A is placed in close vicinity to the rear surface of ...

second embodiment

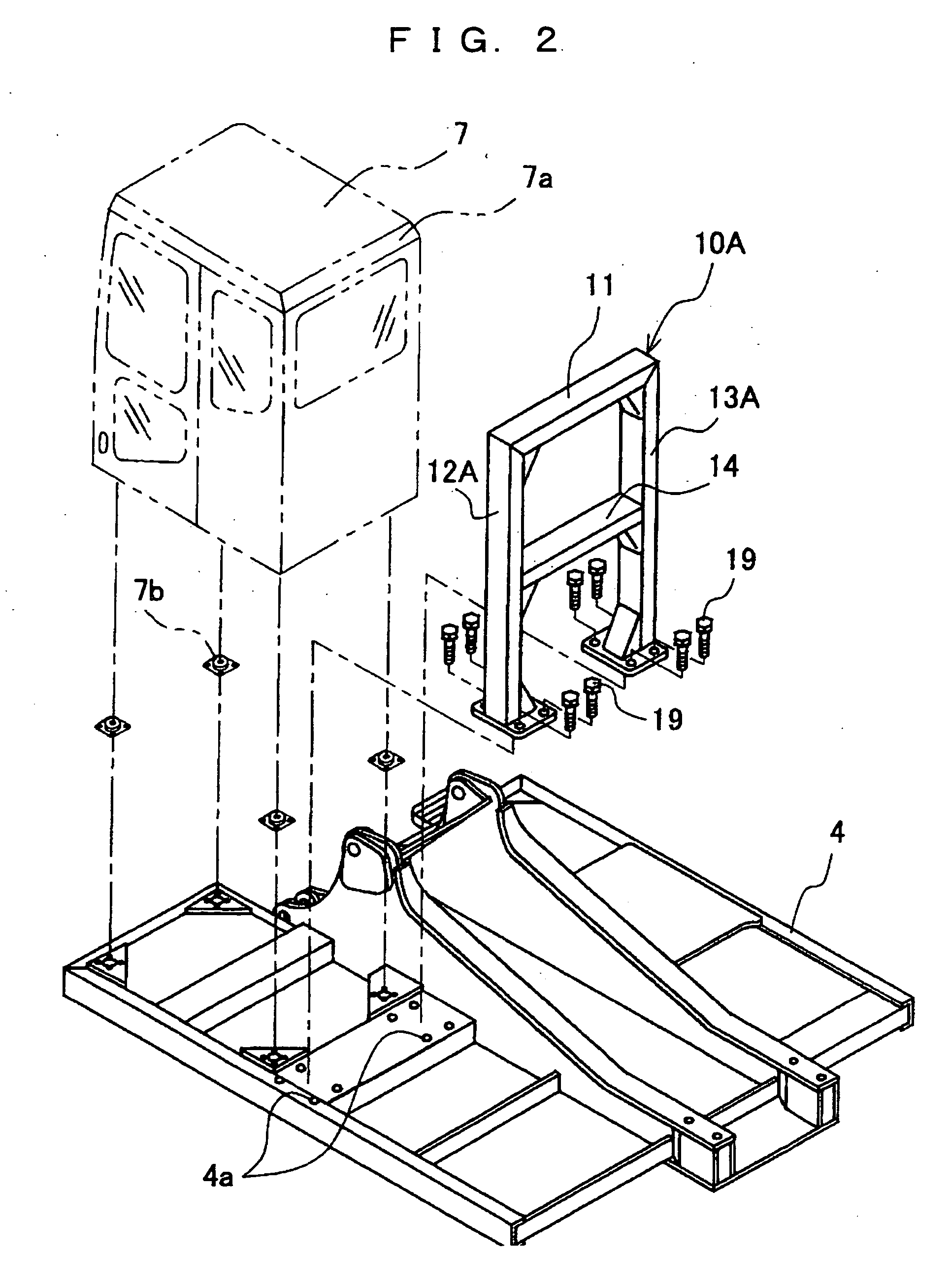

[0036] Based on FIG. 3, a second embodiment will be explained. A portal frame 10B includes the operator's cab protection member 11 placed in close vicinity to the upper side 7a of the rear surface of the operator's cab 7, the left and the right supporting columns 12A and 13B (supporting members 12A and 13B) which are mounted to the left and the right of the operator's cab protection member 11 and are provided upright in the vertical direction, and a reinforcement member 14 mounted in between the intermediate portions in the vertical direction of the left and right supporting columns 12A and 13B. A mounting seat 4c is placed on an outside surface of the vertical plate member 4b at the side of the operator's cab 7 among a pair of left and right vertical plate members 4b and 4b which are provided at the upper revolving superstructure frame 4 and support a base end portion of the working machine 5 (see FIG. 1) to be swingable up and down. The supporting column 13B placed at an inner sid...

third embodiment

[0040] Based on FIG. 4, a third embodiment will be explained. A portal frame 10C (an operator's cab protection frame 10C) includes the operator's cab protection member 11 placed in close vicinity to the upper side 7a of the rear surface of the operator's cab 7, left and right supporting columns 12B and 13C (supporting members 12B and 13C) which are mounted to the left and the right of the operator's cab protection member 11 and are provided upright in the vertical direction, and the reinforcement member 14 mounted in between the intermediate portions in the vertical direction of the left and the right supporting columns 12B and 13C. The portal frame 10C is placed to straddle the machine room 8b adjacent to a rear side of the operator's cab 7. The left and the right supporting columns 12B and 13C of the portal frame 10C are respectively fastened to a predetermined numbers of threaded holes 4f of a mounting seat 4e which is placed at the outside surface of the upper revolving superstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com