Apparatus and method for preventing the bolt carrier of a firearm from moving forward after firing the last round of ammunition, and signaling when the firearm has run out of ammunition.

a technology of bolt carrier and firearm, which is applied in the direction of ammunition loading, weapons, weapon components, etc., can solve the problems of unanticipated running out of ammunition, dry fire, and slow down the response time of operators to refresh firearms magazines, so as to speed up the charging of firearms and remove empty magazines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

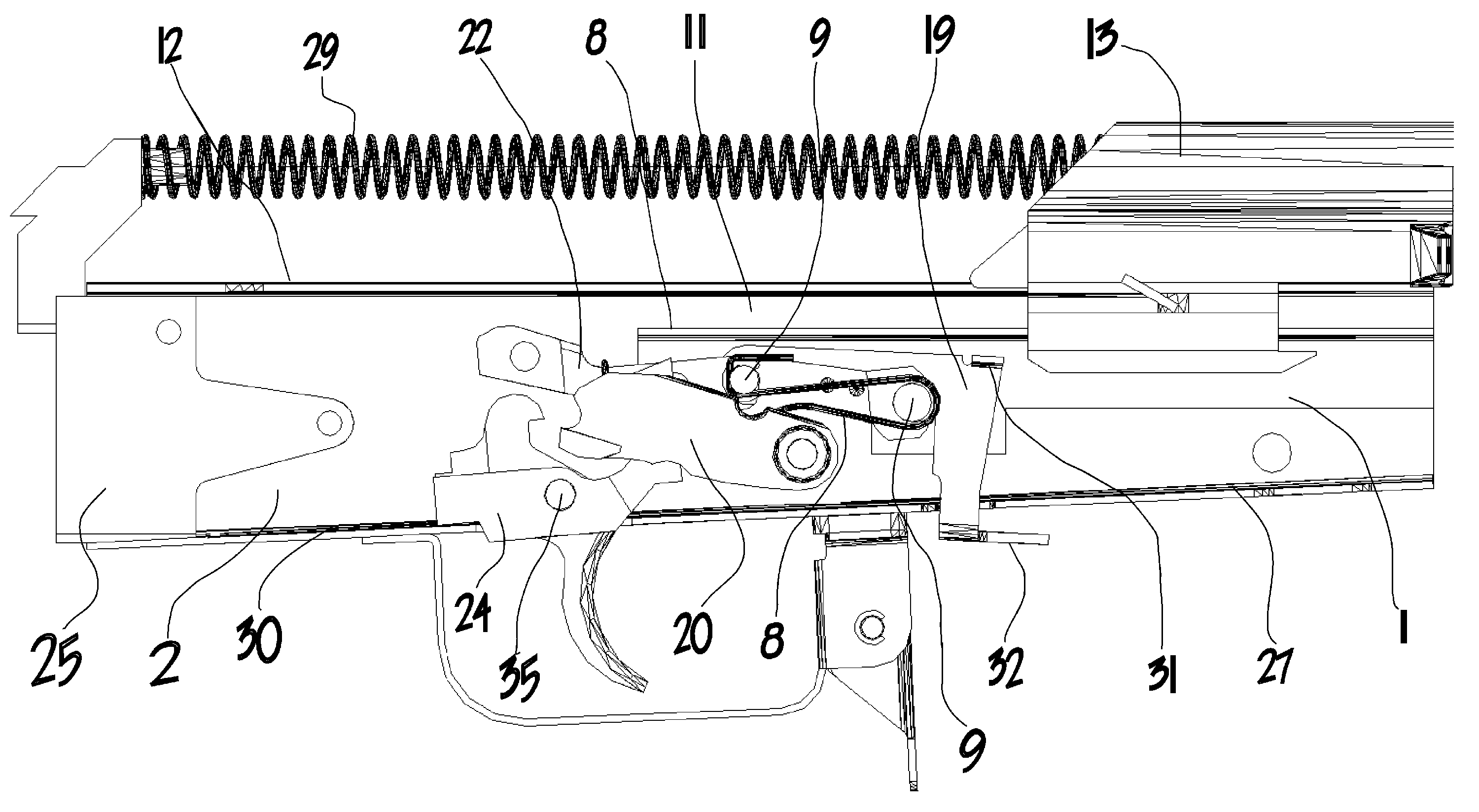

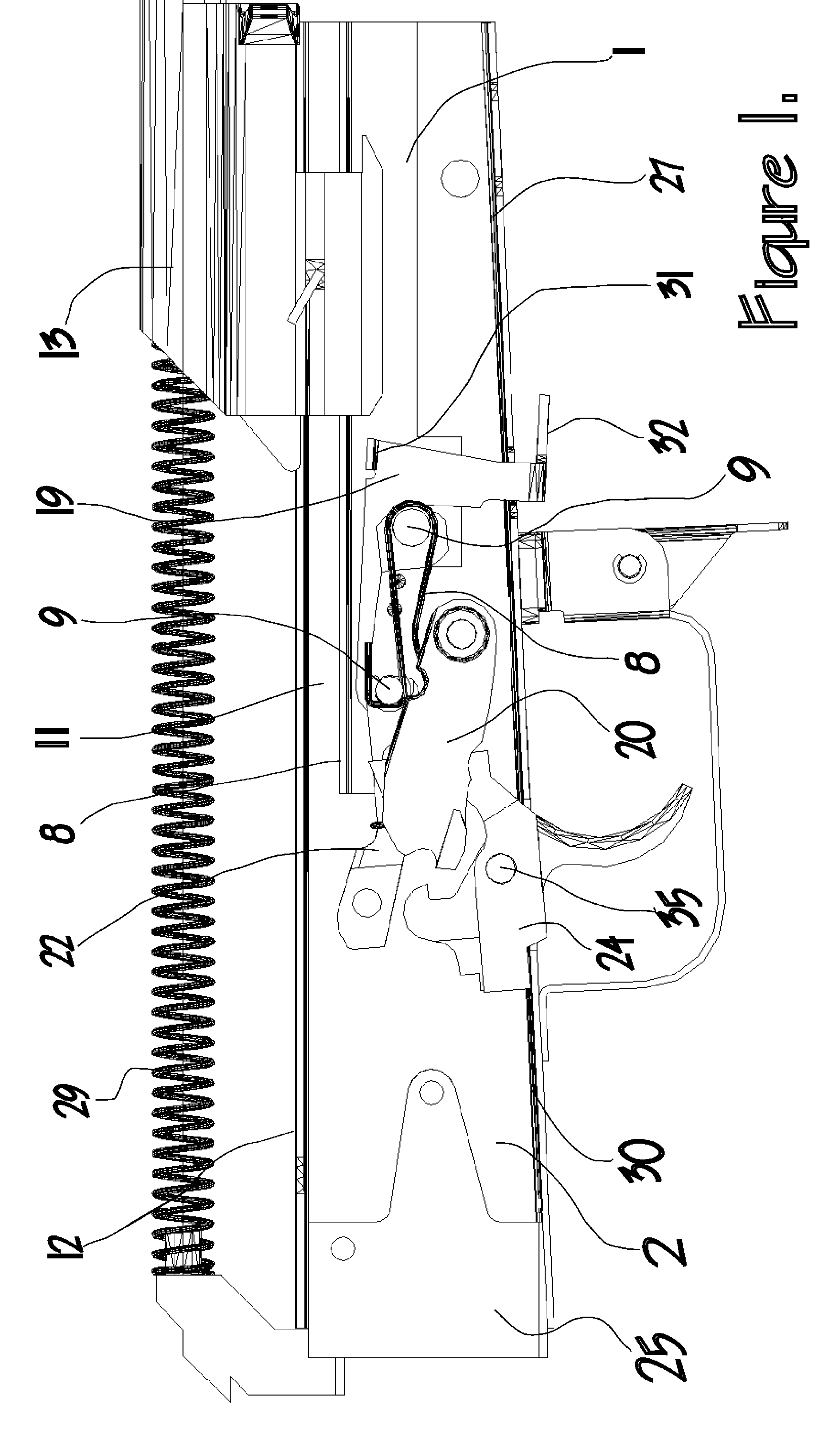

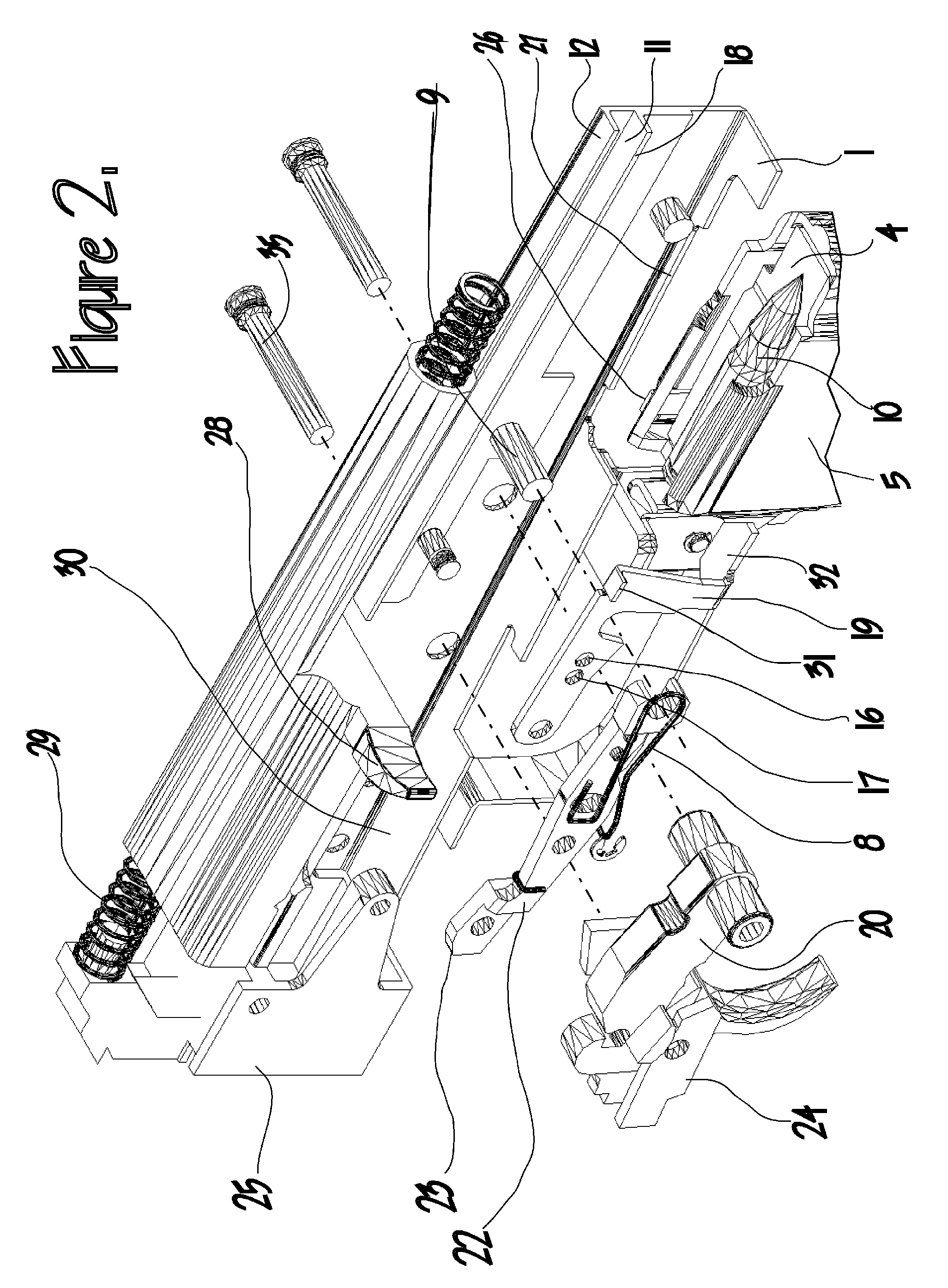

[0012] Referring to FIGS. 1, 2, the rifle includes a channel-shaped receiver 1 having a bottom wall 30, left wall 2, and right wall 3 and a rear block 25. Longitudinally sliding in the upper portion of the receiver 1 is a bolt carrier 13 (or slide), which is supported by means of flanges 12, 18 projecting from the inner surfaces of the side walls. The receiver walls 1, 3 are also connected by means of a semi-permanent solid rivet 9. The trigger assembly includes a trigger 24 pivotally mounted to the receiver 1 by means of a removable pin 35 and having the usual projection for engagement by the trigger finger of an operator. A gas operated piston (not shown) of the bolt carrier 13 to move the latter rearward immediately upon firing of a cartridge. A spiral return spring 29 returns the carrier assembly to its forward locked position after firing. The removable box magazine is comprised of the housing 5, in which is housed the magazine follower 4 which is constrained to move in the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com