Sheet-metal elements made of flexibly rolled material strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

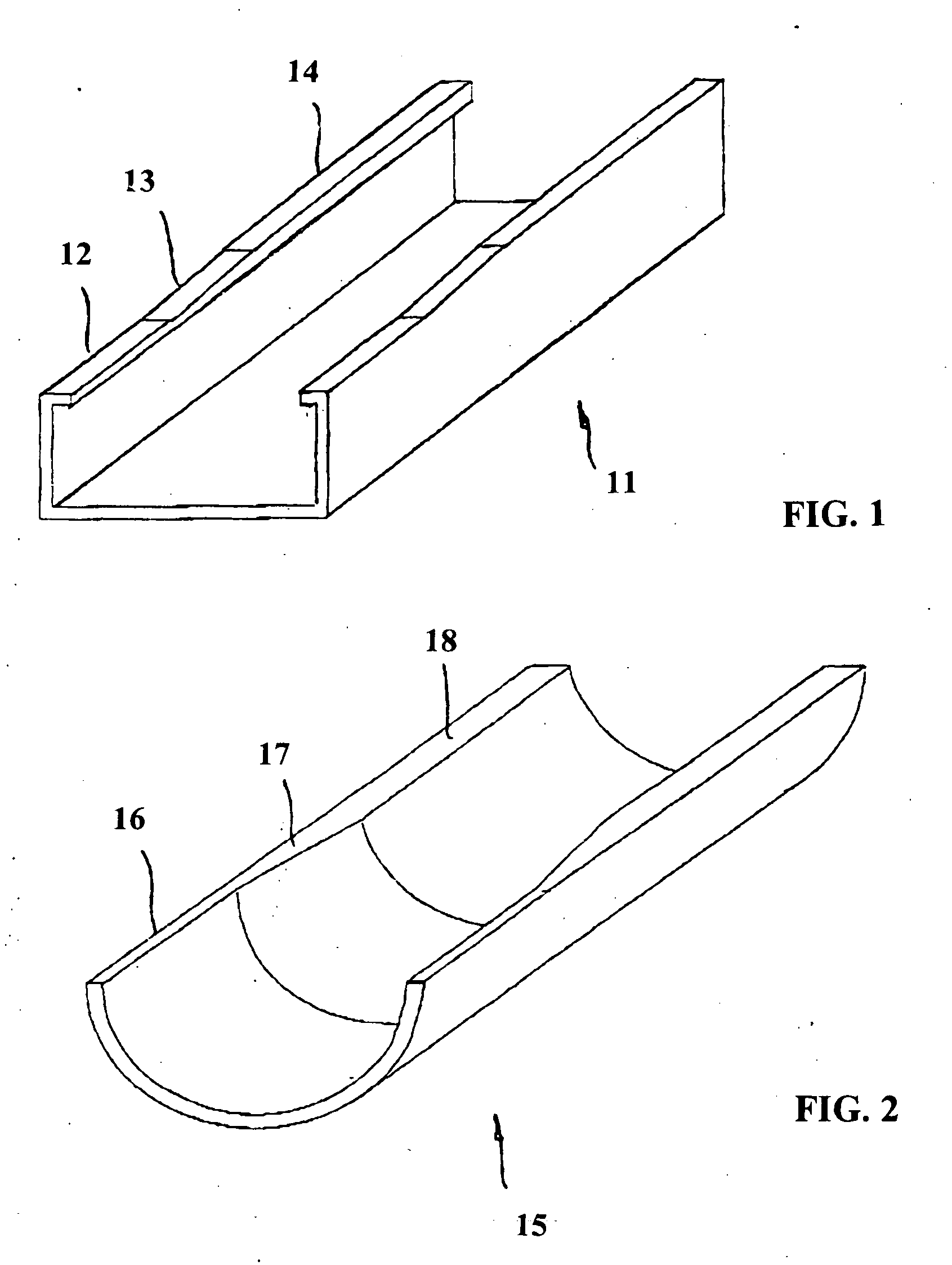

[0008] Insofar as flexibly rolled material strip is discussed here, this includes both the possibility of reshaping the material strip, which has not been divided, after rolling to form sheet-metal elements and then cutting to length. Also the material strip may be cut to length after the flexible rolling and then reshaped to form sheet-metal elements. And finally, the material strip may be cut to length before the flexible rolling, and then reshaping flexibly rolled blanks to form sheet-metal elements.

[0009] The sheet-metal elements described hereinafter preferably comprise sheet-metal elements manufactured of cold-rolled material strip.

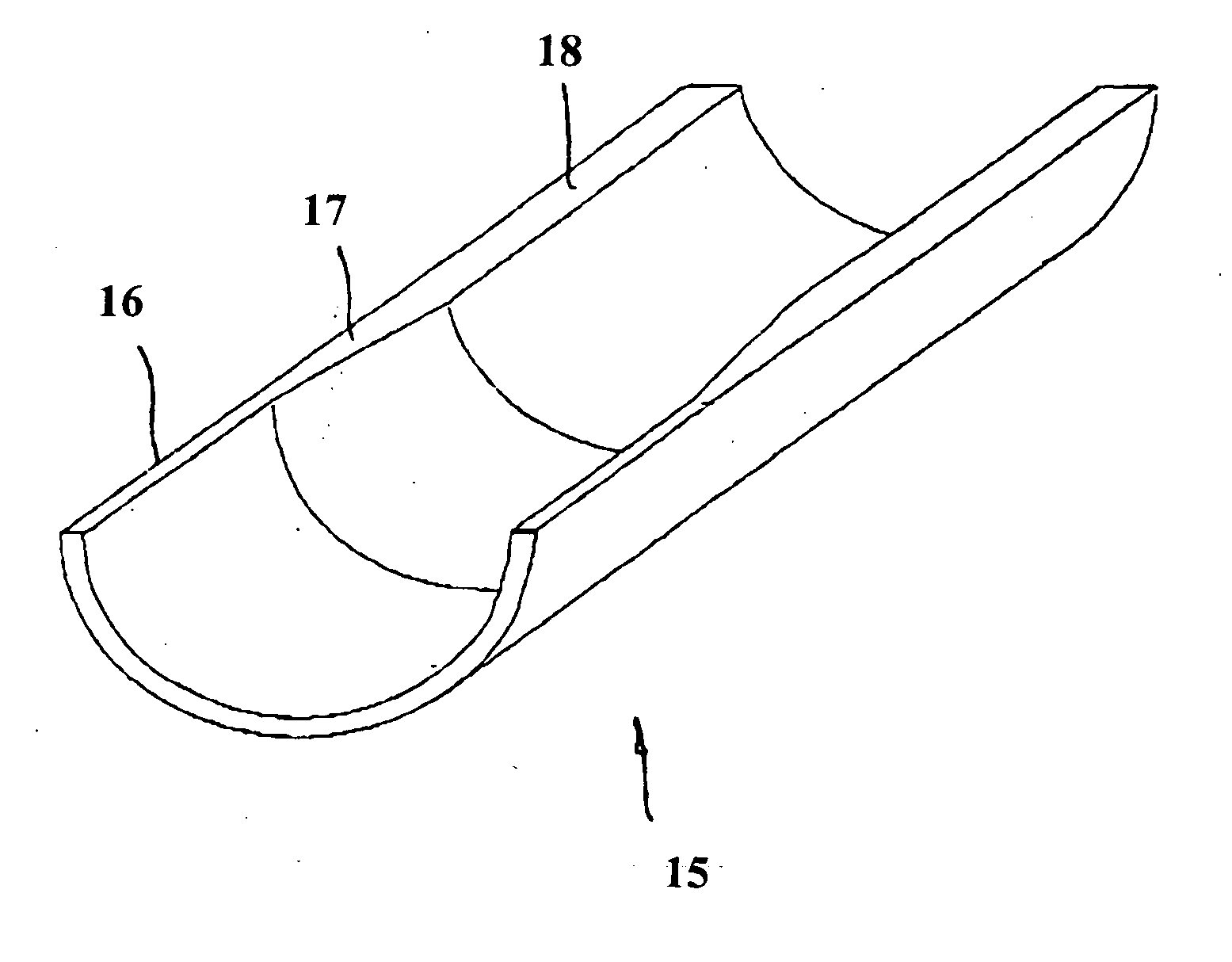

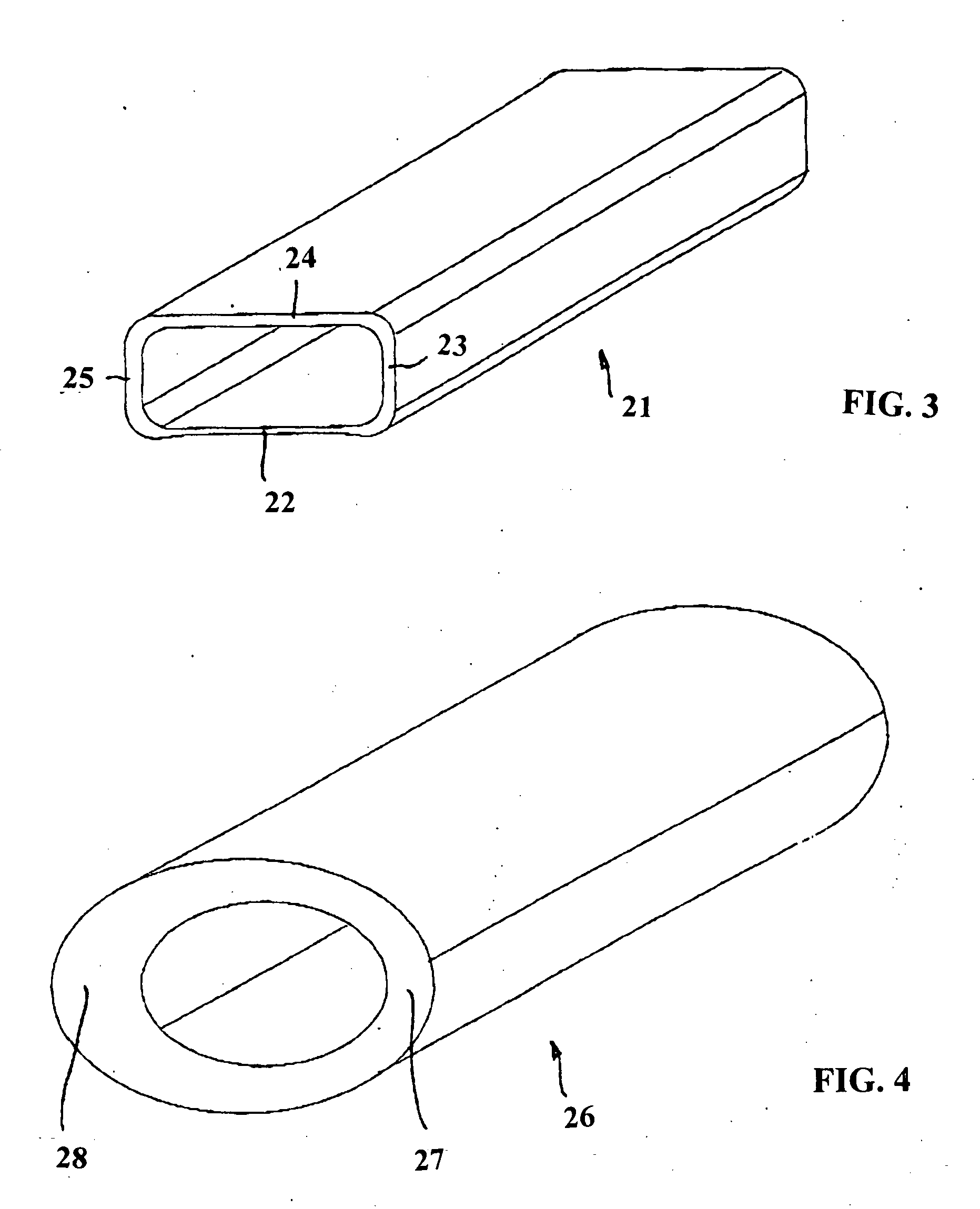

[0010] A first solution according to the invention consists in a sheet-metal element reshaped about the longitudinal direction of the strip from a flexibly rolled material strip having different thicknesses in the longitudinal direction of the strip to form a tube or profile body having an out-of-round cross-section and variable wall thickness ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com