Method and apparatus of cryogenic cooling for high temperature superconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

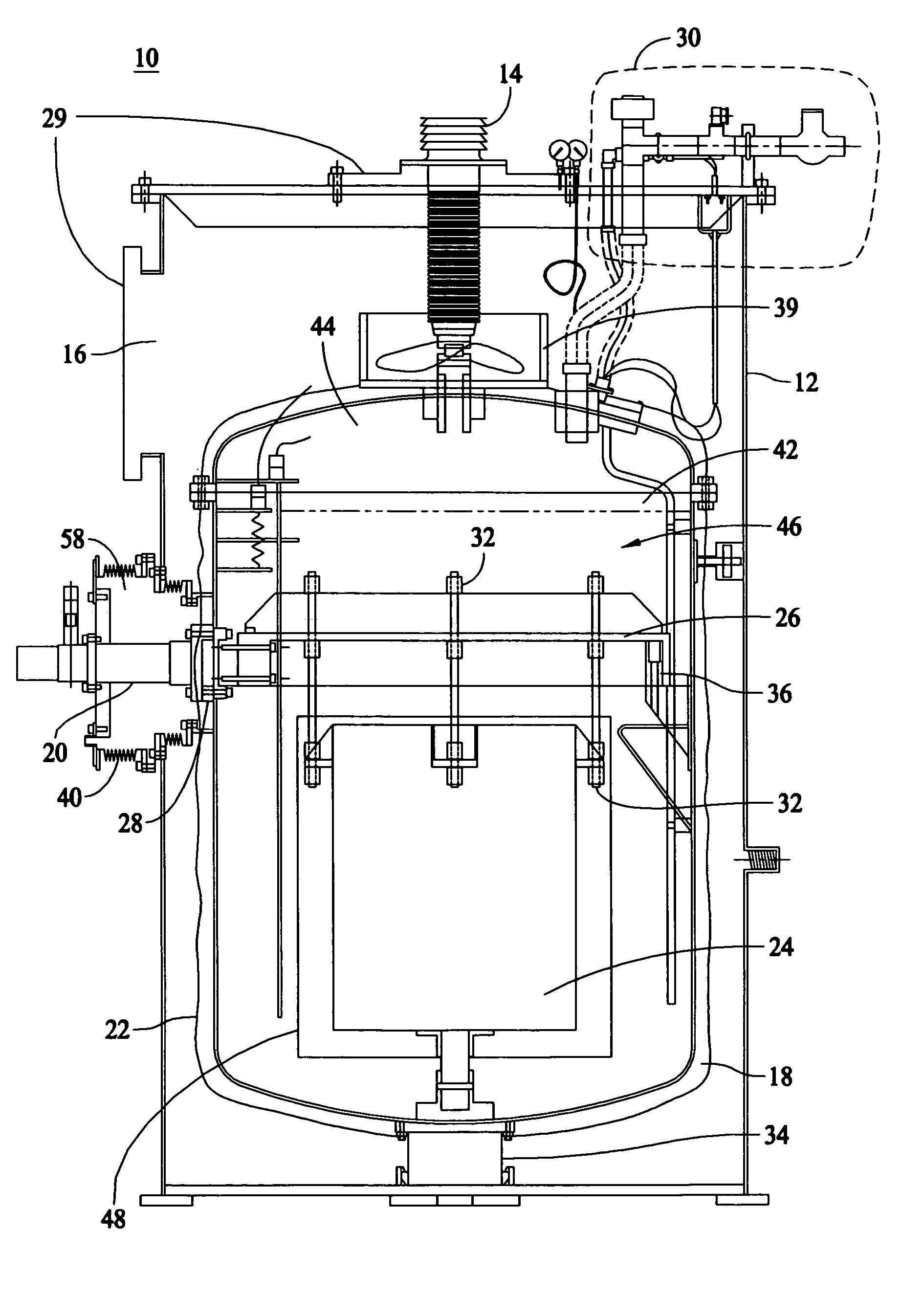

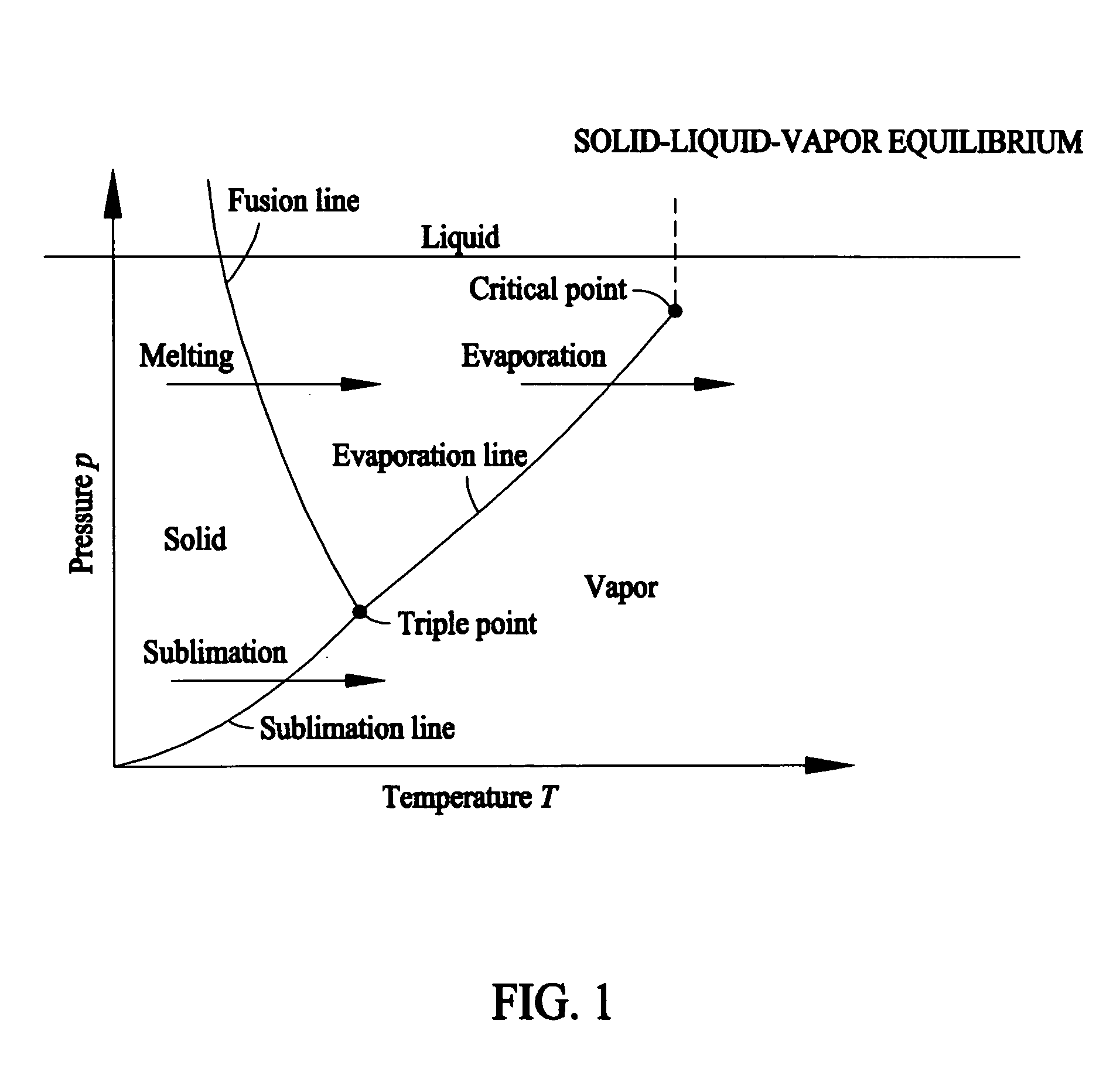

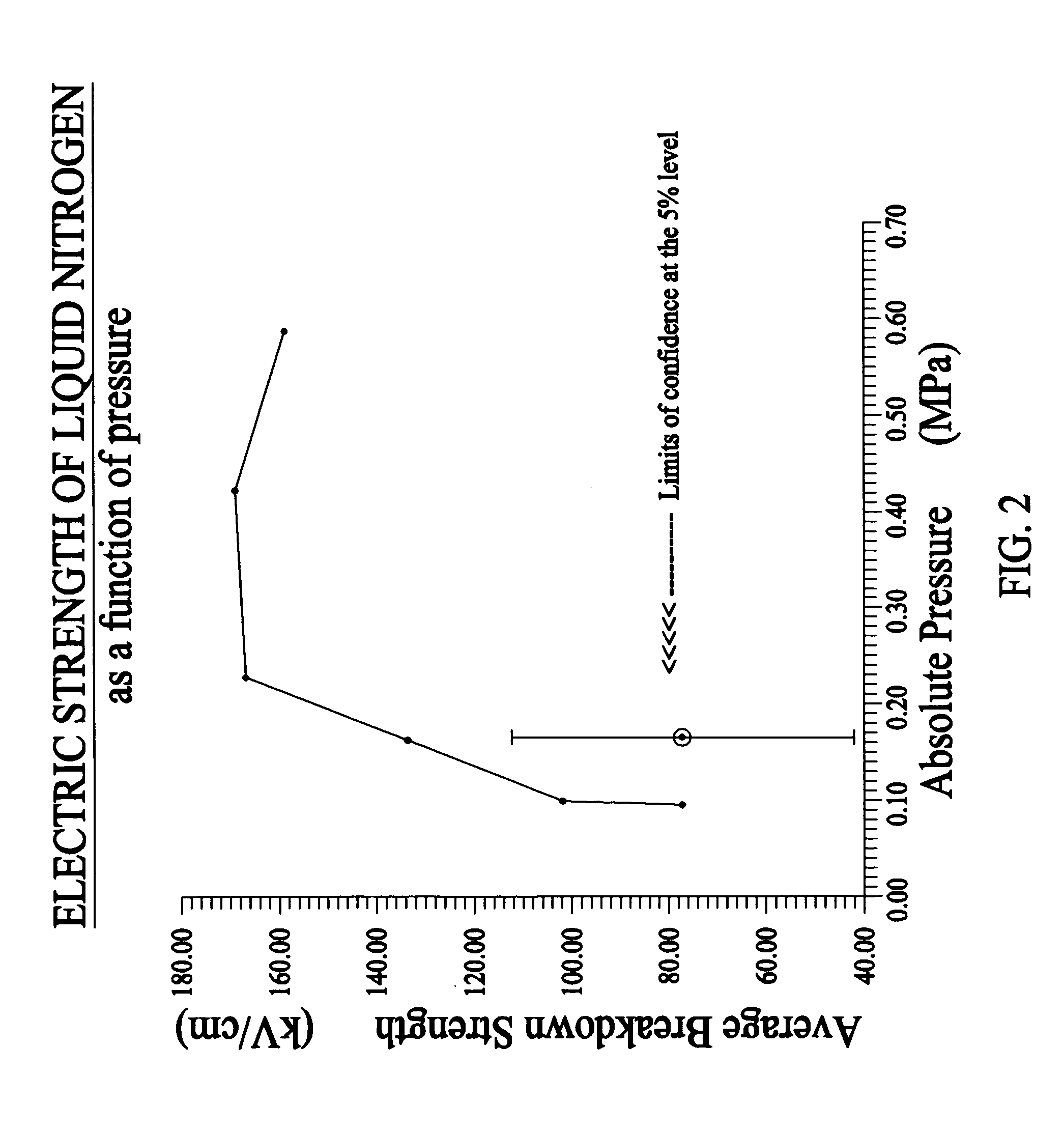

[0013] The present invention generally relates to a cryogenic cooling systems for HTS device that have high-voltage applications even though it can also be applied to HTS devices that have other general purposes. The method of providing such a cryogenic cooling system includes maintaining a pressurized cryogen region that comprises a liquid as well as gaseous region, to above one absolute atmospheric pressure. The method further involves maintaining temperature of part or all of the liquid cryogen regions to below its boiling temperature (sub-cooled) using cooling means such as a cryogenic refrigerator (cryocooler).

[0014] Briefly, in accordance with the present invention, a method is provided for designing a liquid-cryogen-based cryogenic cooling system for HTS devices that have the characteristics of lower operating temperature of liquid cryogen to improve the critical current density of HTS materials while at the same time substantially increasing the dielectric strength of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com