Apparatus for transferring loose material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

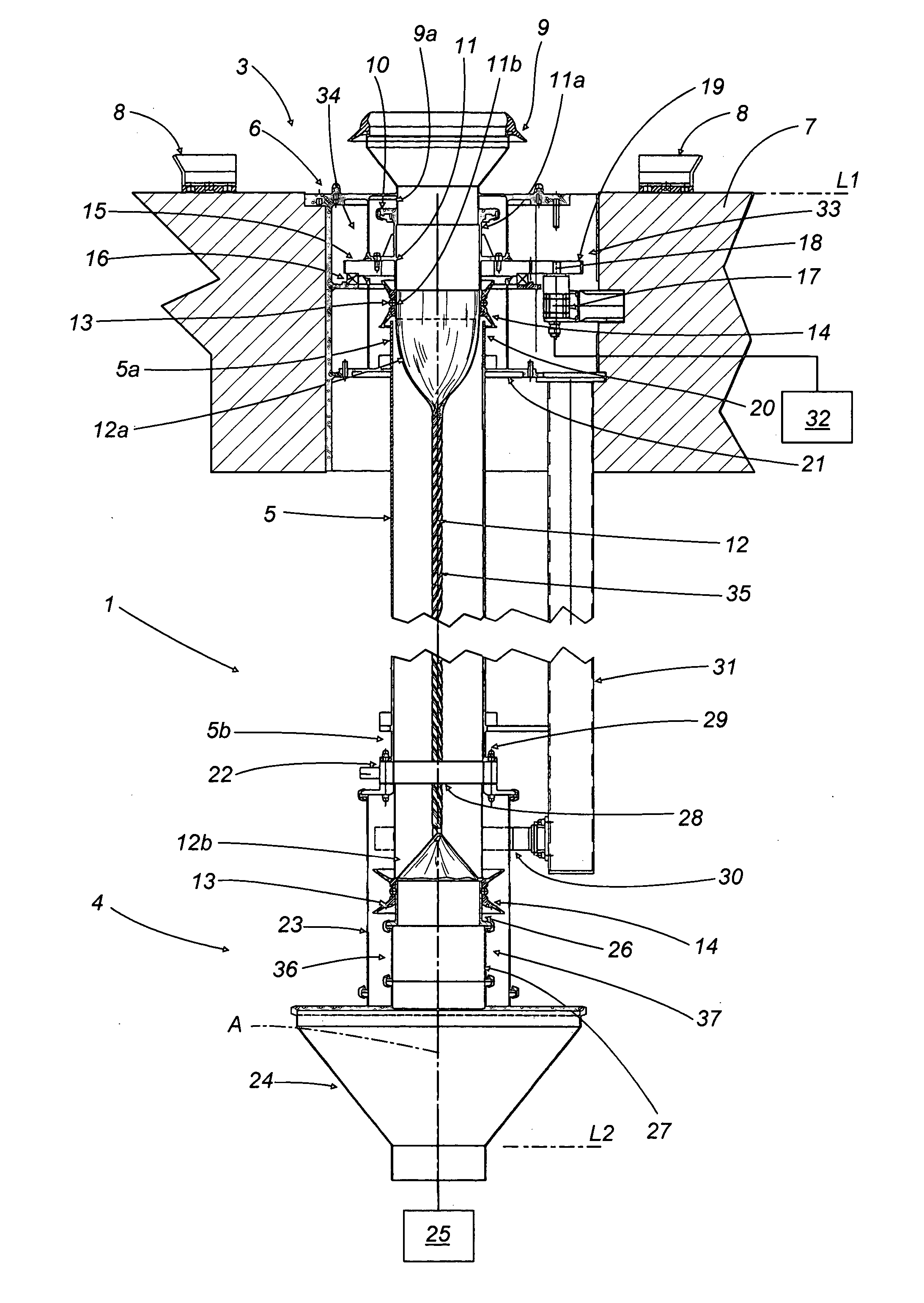

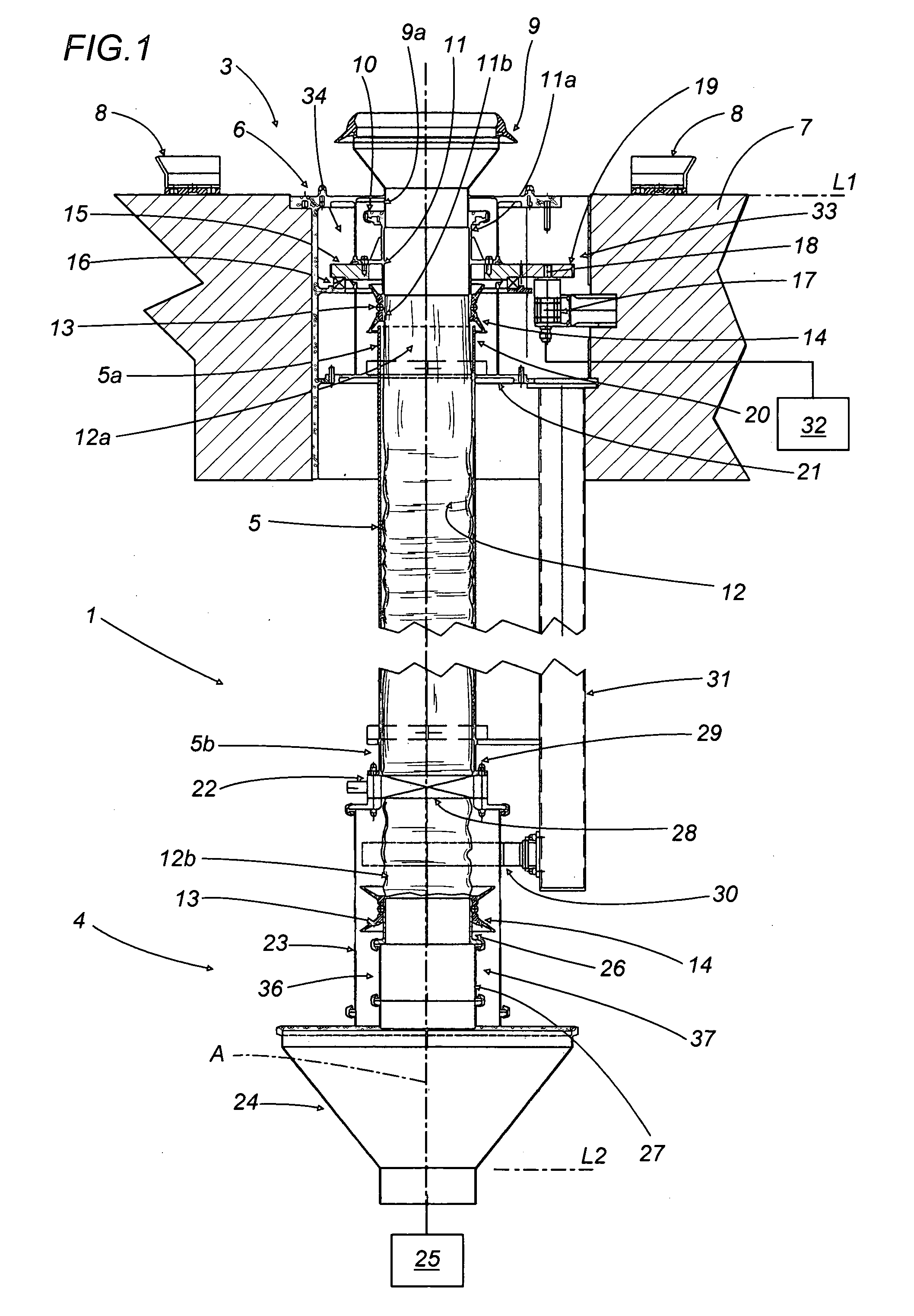

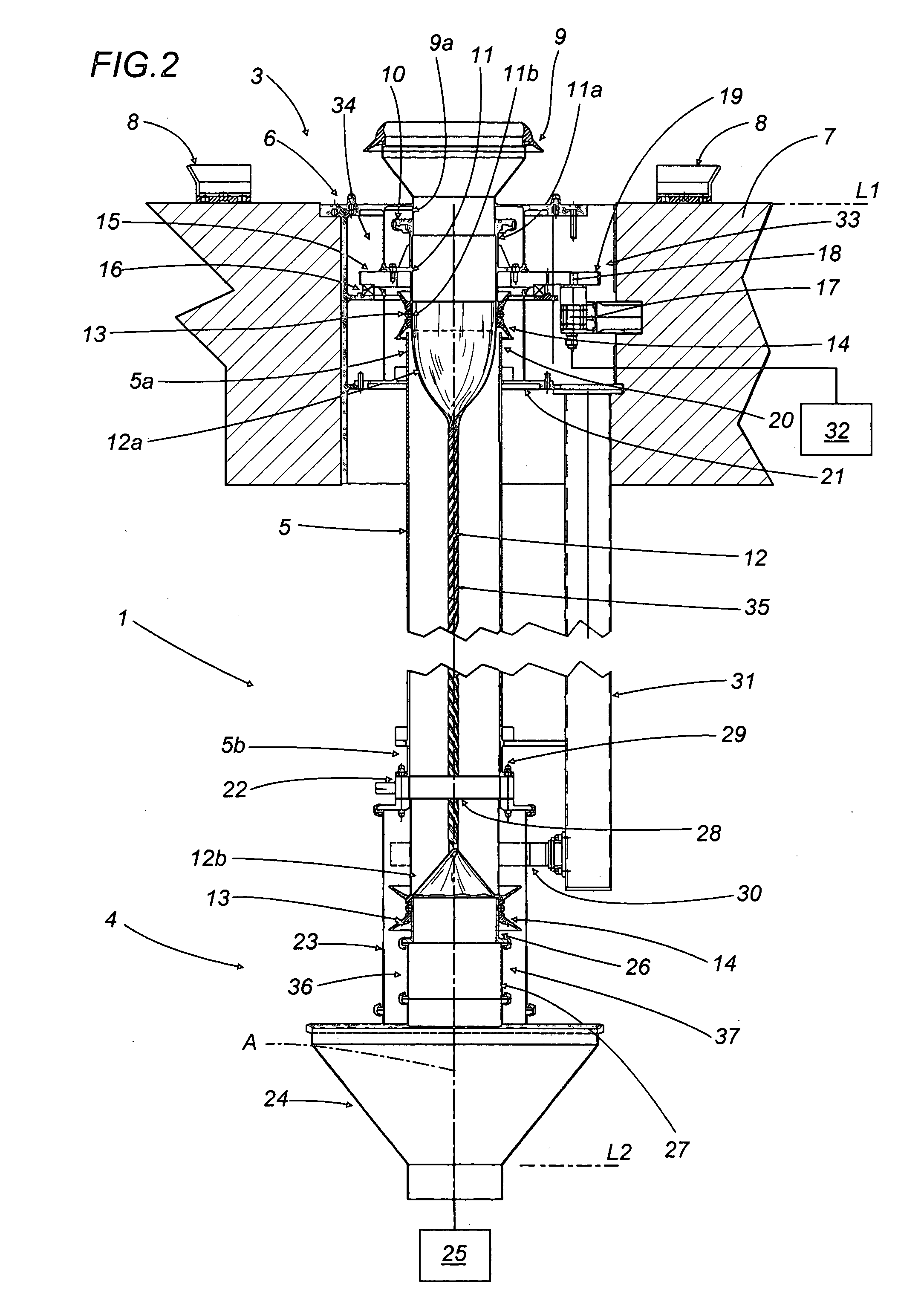

[0021] With reference to the accompanying drawings, the numeral 1 denotes as a whole an apparatus for transferring a loose material 2 from a station 3 for unloading a container not illustrated to a receiving station 4.

[0022] The unloading station 3 is located at a first, upper level L1 and the receiving station 4 is located at a second, lower level L2.

[0023] A rigid pipe 5, advantageously made of polycarbonate or other transparent material, connects the stations 3 and 4 extending vertically along its central axis A.

[0024] The apparatus 1 comprises a supporting structure 6 connected to a portion 7 of a floor made of brickwork or other material.

[0025] The accompanying drawings illustrate a non-limiting example in which there is a difference in the height of a material unloading station and a relative receiving station and in which the material is basically transferred by gravity.

[0026] At the first level L1 the structure 6 comprises a cup 8 for positioning a container, not illust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com