A biodegradable ceramic fiber composition for a heat insulating material

A technology of ceramic fiber and thermal insulation material, which is applied to containers with multiple items, holders for glass cups or glass bottles, containers, etc., which can solve the problems of being unsuitable for large-scale production and poor high-temperature thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

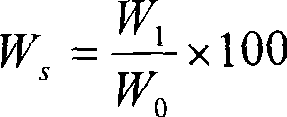

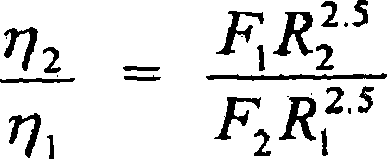

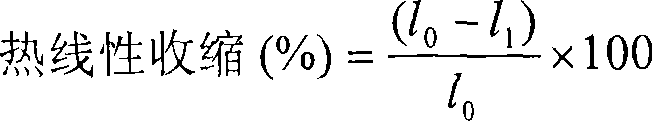

[0082] Test Example 2: Biodegradability and Thermal Linear Shrinkage

[0083] Table 3 below shows the dissolution rate constant and thermal linear shrinkage (1100° C. / 24 hours) in artificial body fluids of each fiber composition prepared according to the foregoing examples and comparative examples.

[0084] Table 3: Dissolution rate constants and thermal linear shrinkage in artificial body fluids

[0085] serial number

Dissolution rate constant

K dis (ng / cm 2 ·hr) Linear shrinkage (%)

(1100℃ / 24 hours) Example 1 252 1.5 Example 2 273 2.3 Example 3 302 1.6 Example 4 423 2.1 Example 5 451 2.4 Example 6 380 1.9 Example 7 326 2.4 Comparative example 1 3 1.4 Comparative example 2 15 1.1 Comparative example 3 129 2.7 Comparative example 4 182 2.9 Comparative example 5 116 2.6 Comparative example 6 85 2.1 Comparative example 7 550 6.9 Comparative example 8 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com