Calcium aluminate cement preparing method

A technology of calcium aluminate cement and calcium carbonate, which is applied in the field of inorganic non-metallic materials, can solve the problems of long production cycle, great environmental hazards, and high synthesis temperature, and achieve the effects of reduced production costs, simple and economical preparation process, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

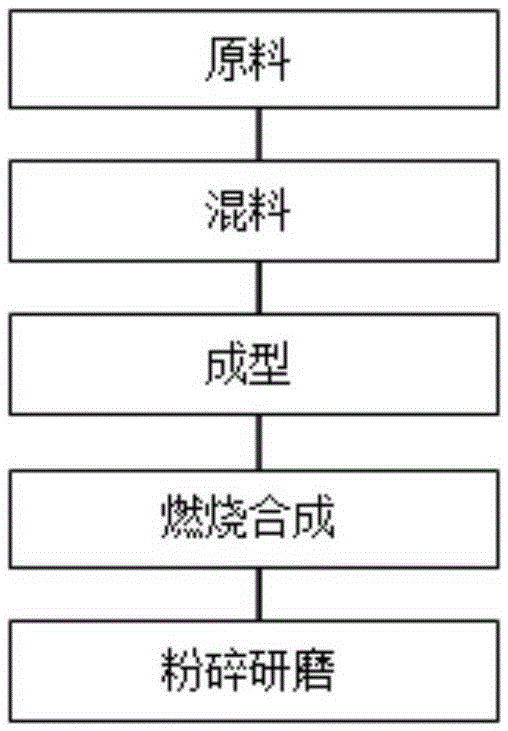

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment adopts calcium carbonate (purity ≥ 99.0%), aluminum powder (purity ≥ 99.0%) and aluminum oxide (purity ≥ 99.0%) as raw materials, by mass percentage, calcium carbonate (purity ≥ 99.0%) is 18%, Aluminum powder (purity ≥ 99.0%) is 40%, alumina (purity ≥ 99.0%) is 42%; put the uniformly mixed raw materials into a mold, and then dry press them to form a diameter of 20mm and a height of 15mm , a cylindrical sample with a relative density of 50%; after the molding is completed, the sample is demolded, and then placed in a self-propagating high-temperature reaction furnace, and a C-Ti igniter is placed on the sample to conduct a self-propagating high-temperature synthesis reaction Initiated by the heat generated by the Ti-C reaction placed on the top of the sample, while the Ti and C reactions are initiated by a tungsten wire;

[0034] The reaction chamber is filled with argon gas, the pressure is 0.1MPa, and the sample is ignited to undergo a self-propa...

Embodiment 2

[0037] The difference between this embodiment and Example 1 is: by mass percentage, calcium carbonate (purity ≥ 99.0%) is 28%, aluminum powder (purity ≥ 99.0%) is 38%, aluminum oxide (purity ≥ 99.0%) is 34% %;

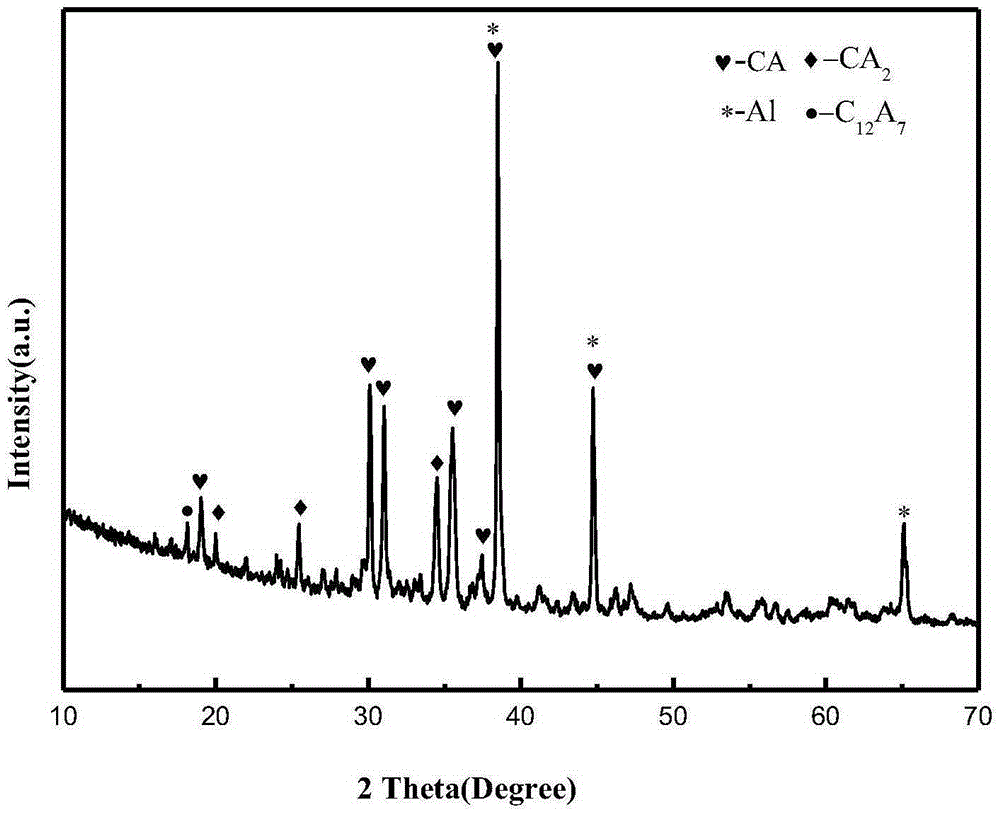

[0038] The calcium aluminate cement prepared in embodiment 2 has been carried out X-ray diffraction to obtain XRD collection of patterns see image 3 ,Depend on image 3 It can be seen that the calcium aluminate cement prepared in Example 2 contains calcium aluminate (CaAl 2 o 4 , abbreviated as CA), calcium dialuminate (CaAl 4 o 7 , abbreviated as CA 2 ) and dodecacalcium heptaaluminate (Ca 12 Al 14 o 33 , abbreviated as C 12 A 7 ) powder, by mass percentage, calcium monoaluminate accounts for 68% to 72%, calcium dialuminate accounts for 10% to 15%, and the balance is dodecaaluminate heptaaluminate and trace impurities.

Embodiment 3

[0040] The difference between this embodiment and Example 1 is: by mass percentage, calcium carbonate (purity ≥ 99.0%) is 34%, aluminum powder (purity ≥ 99.0%) is 23%, aluminum oxide (purity ≥ 99.0%) is 43% %;

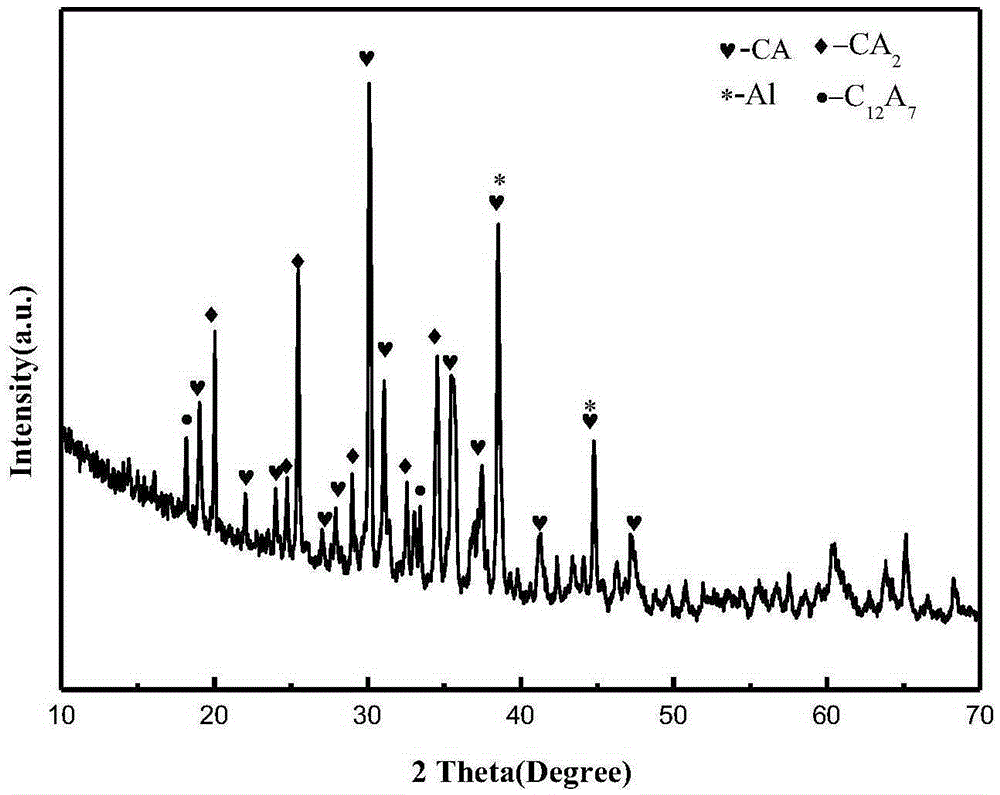

[0041] The calcium aluminate cement prepared in embodiment 3 has been carried out X-ray diffraction to obtain XRD collection of patterns see Figure 4 ,Depend on Figure 4 It can be seen that the calcium aluminate cement prepared in Example 1 contains calcium monoaluminate (CaAl 2 o 4 , abbreviated as CA), calcium dialuminate (CaAl 4 o 7 , abbreviated as CA 2 ) and dodecacalcium heptaaluminate (Ca 12 Al 14 o 33 , abbreviated as C 12 A 7 ) powder, by mass percentage, calcium monoaluminate accounts for 67% to 75%, calcium dialuminate accounts for 5% to 9%, and the balance is dodecacalcium heptaaluminate and trace impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com