Anisotropic touch screen element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

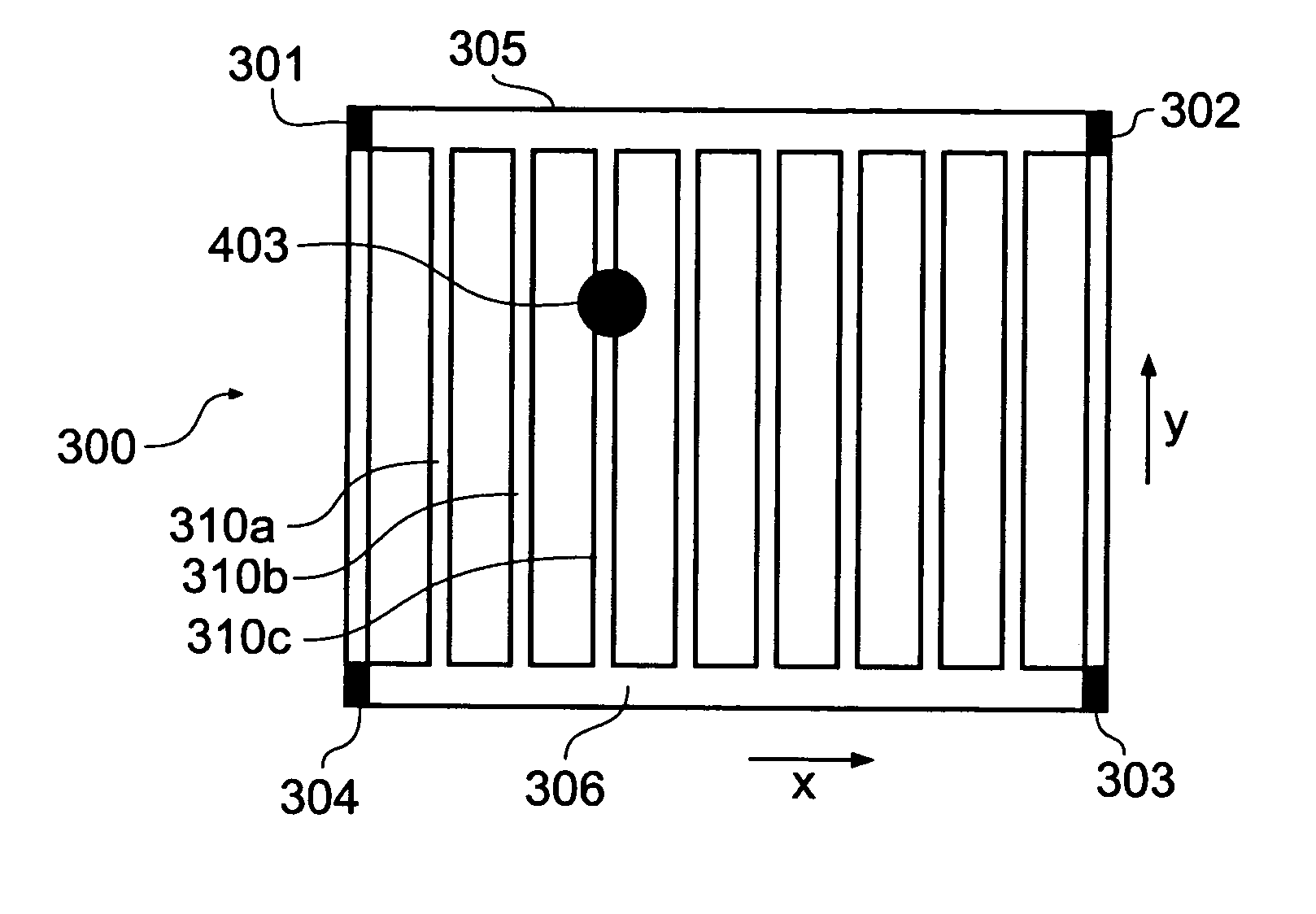

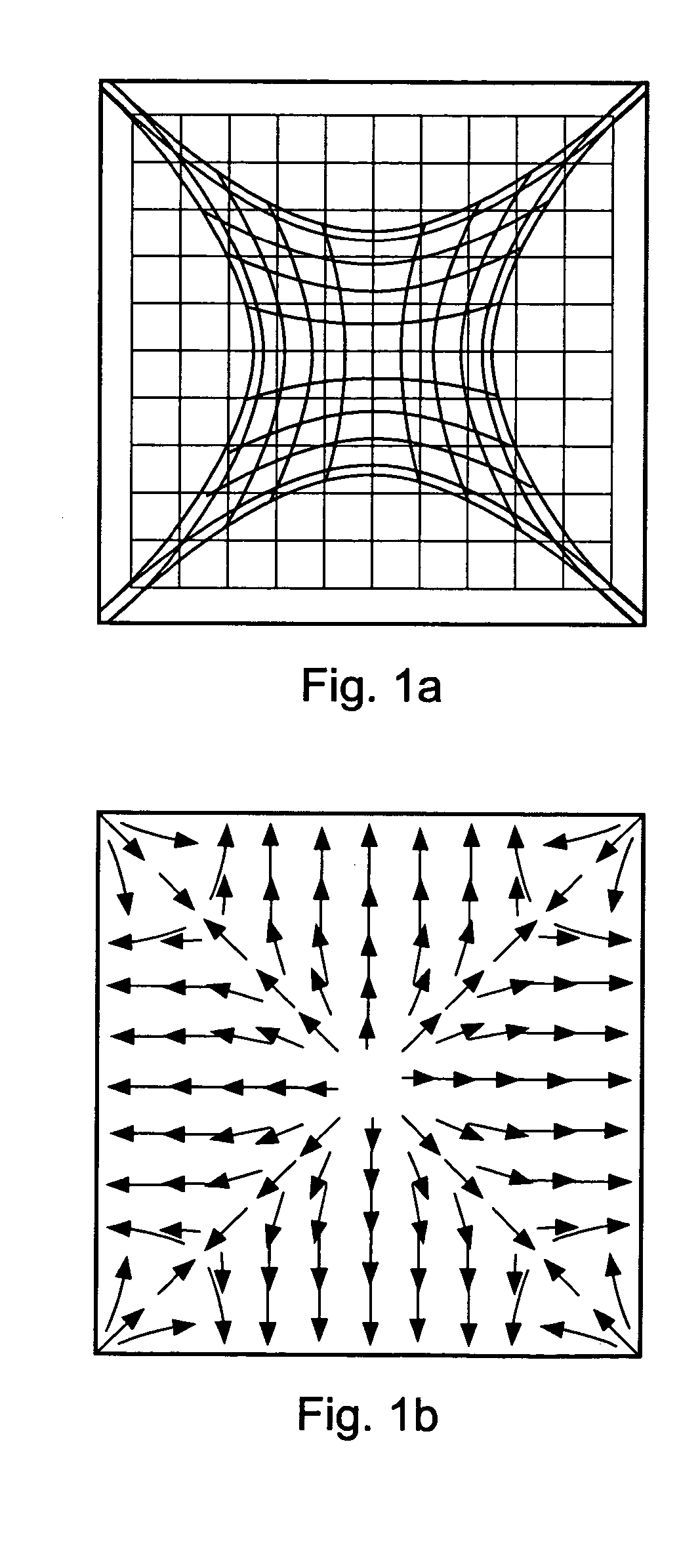

FIGS. 1a and 1b show the prior art for 2DxT technology prior to the use of correction hardware or algorithms. The pin cushion effect of FIG. 1a is well understood. It arises from the current sharing of capacitance-induced flows from the point of touch to the four connection points; the effect is seen in both 2DCT's and in 2DRT 5-wire touch screens which rely on a galvanic version of the same voltage gradients as a 2DCT, but with a flexible ‘pickoff’ cover sheet that deflects and connects to the 2DRT under pressure. The pin cushion effect in these elements increases as the location of touch becomes more distant from all connection points, along an edge; it is at its worst at the centers of the screen edges. As shown in FIG. 1b, the current flows establish vectors that introduce a graduated distortion with position, resulting in a parabolic curvature of reported location. The vectors are generally non-orthogonal. Instead the angle and magnitude of correction vary wildly depending on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com