Compressor surge prevention via distinct blade shapes

a technology of distinct blades and compressors, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of external devices such as pneumatic tools, seizing and abruptly stopping working, compressor failure, impeller stalling or failing,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

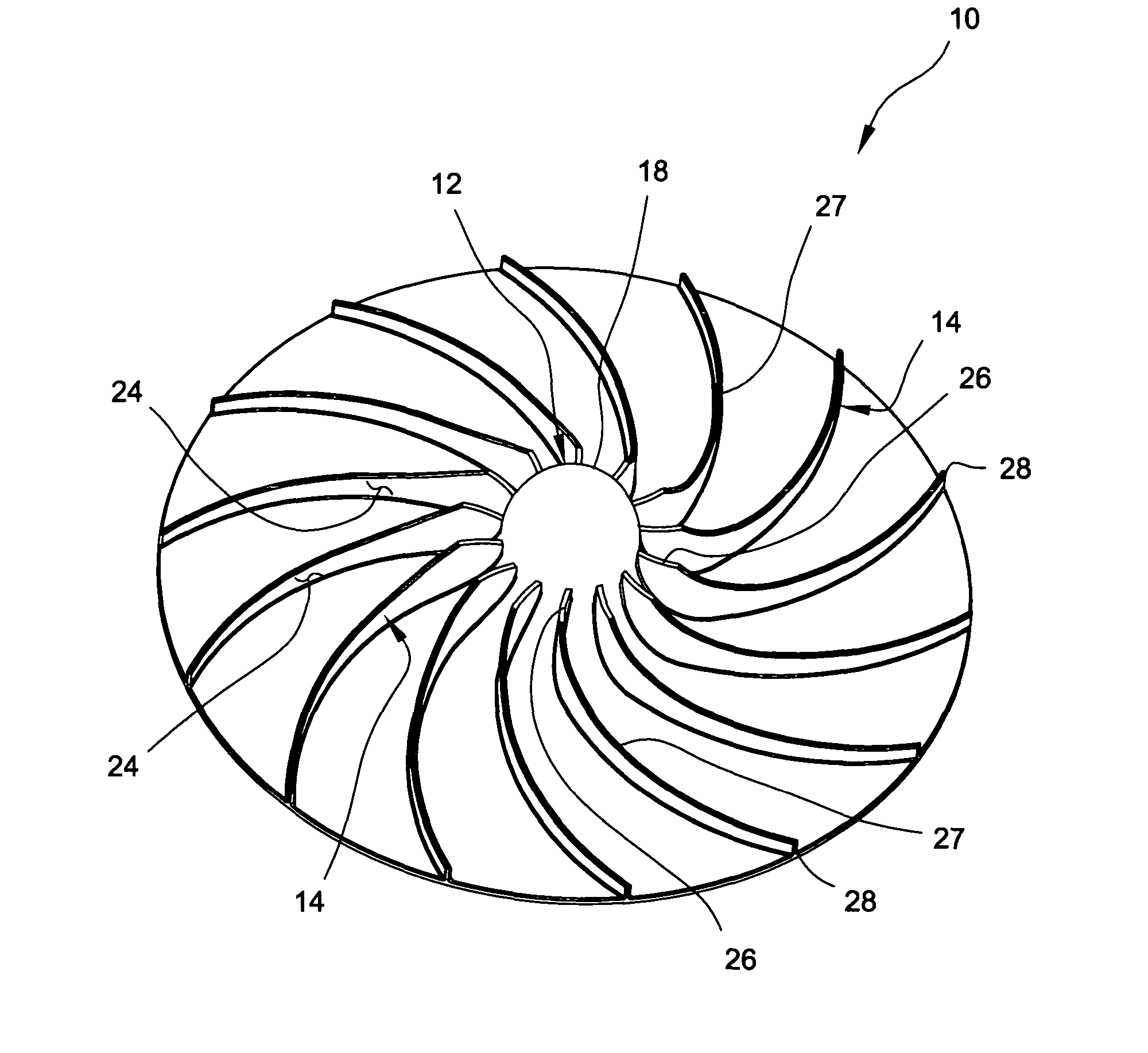

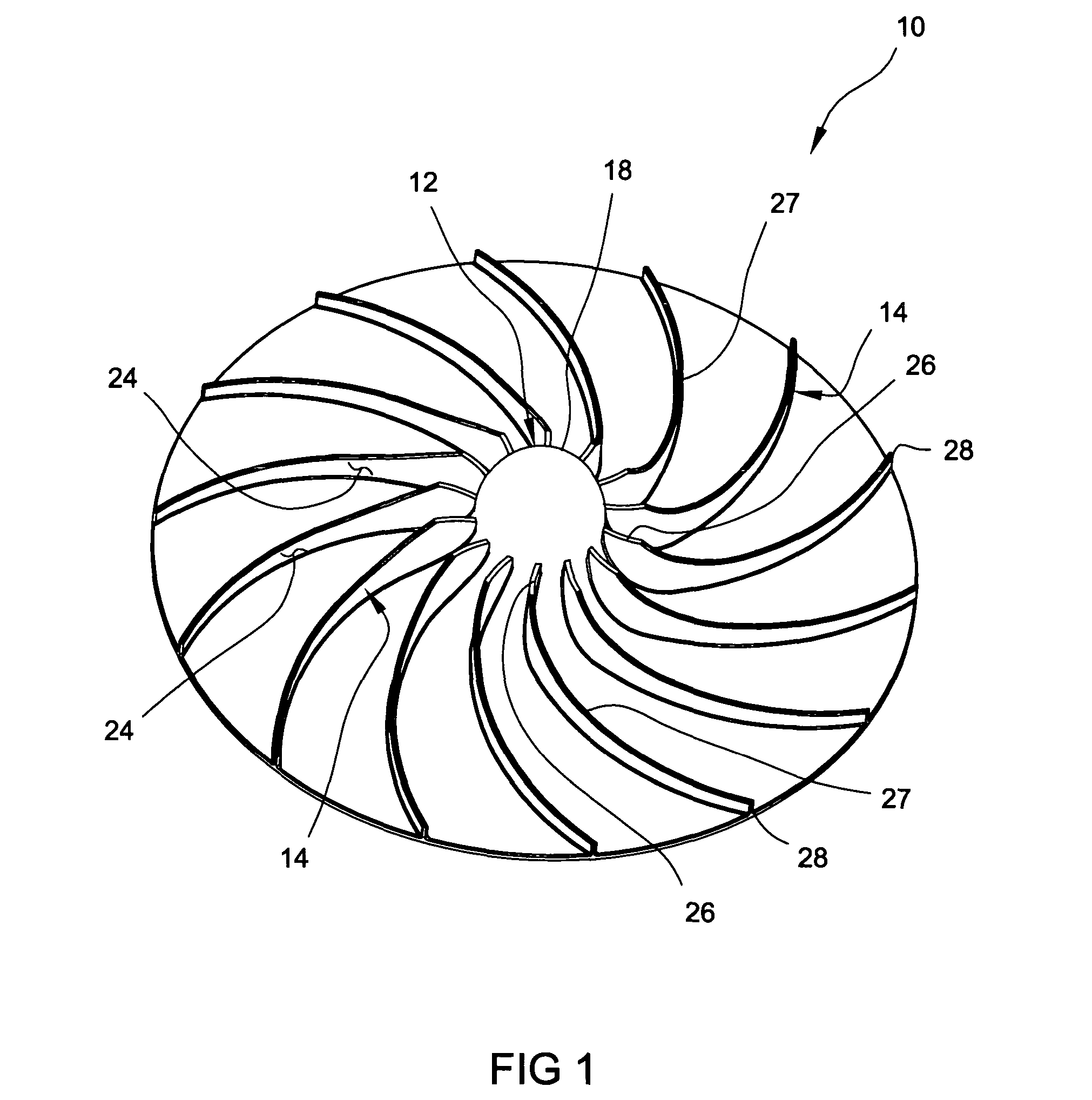

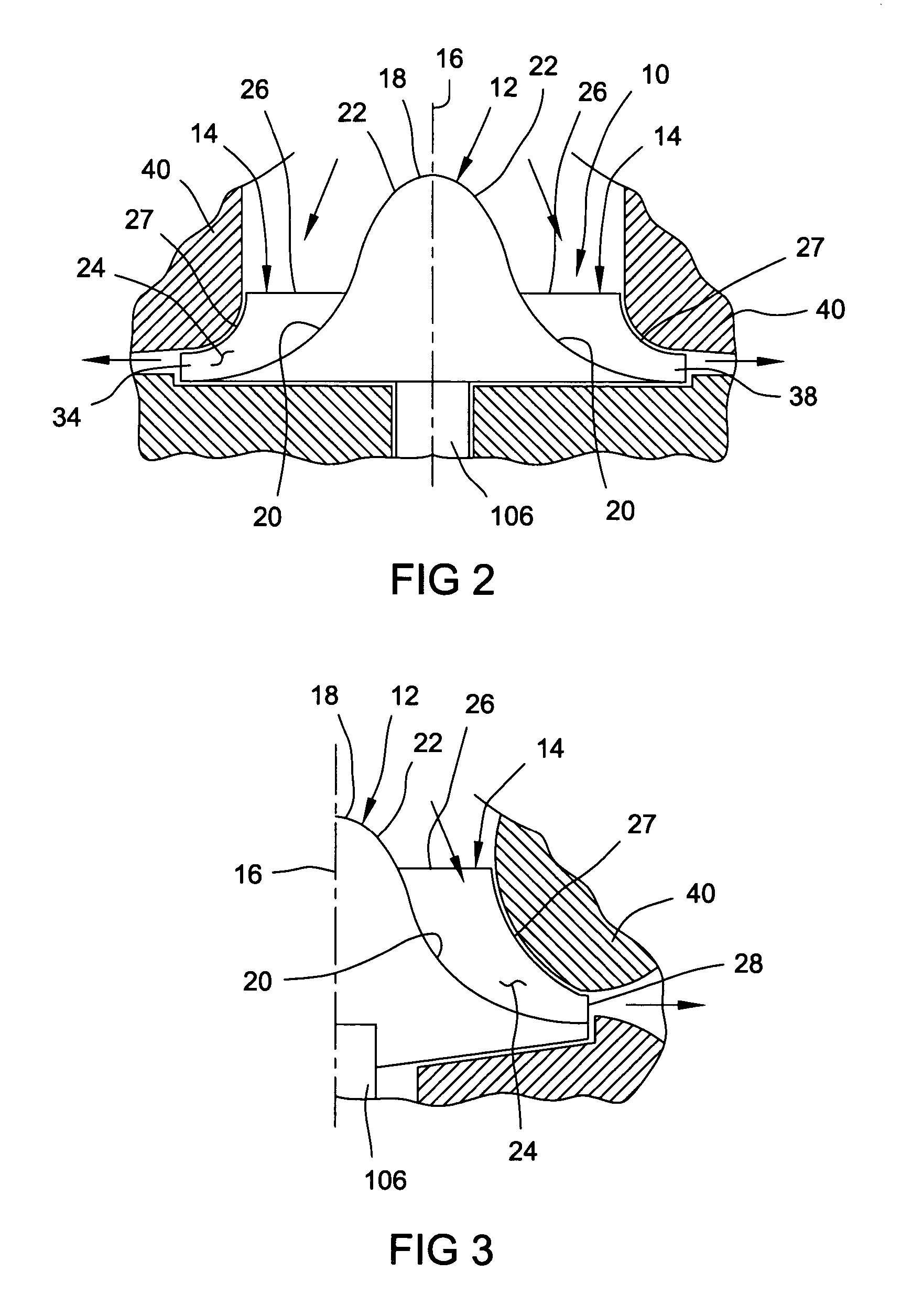

[0023] With reference to the figures, an impeller 10 is provided and includes a hub 12 and a plurality of blades 14 radially extending therefrom. The impeller 10 is operable to capture an air flow through cooperation between the plurality of blades 14 and the hub 12 to compress the air flow and deliver a pressurized air stream as the impeller 10 rotates about a central axis of rotation 16.

[0024] With reference to FIG. 1, the impeller 10 is shown to include a generally circular shape having the hub 12 disposed coaxially with the axis of rotation 16. The hub 12 includes a tip 18 and a hub contour 20 formed proximate each blade 14, as best shown in FIGS. 2 and 3. The hub tip 18 includes a generally arcuate surface 22 for distributing a received air flow to each of the plurality of blades 14.

[0025] With reference to FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com