Snow blower with glide wheels

a technology of snow blower and wheel, which is applied in the direction of snow cleaning, way cleaning, construction, etc., can solve the problems of operator discomfort, physical strenuous operation, and inability to cleanly remove snow, so as to reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

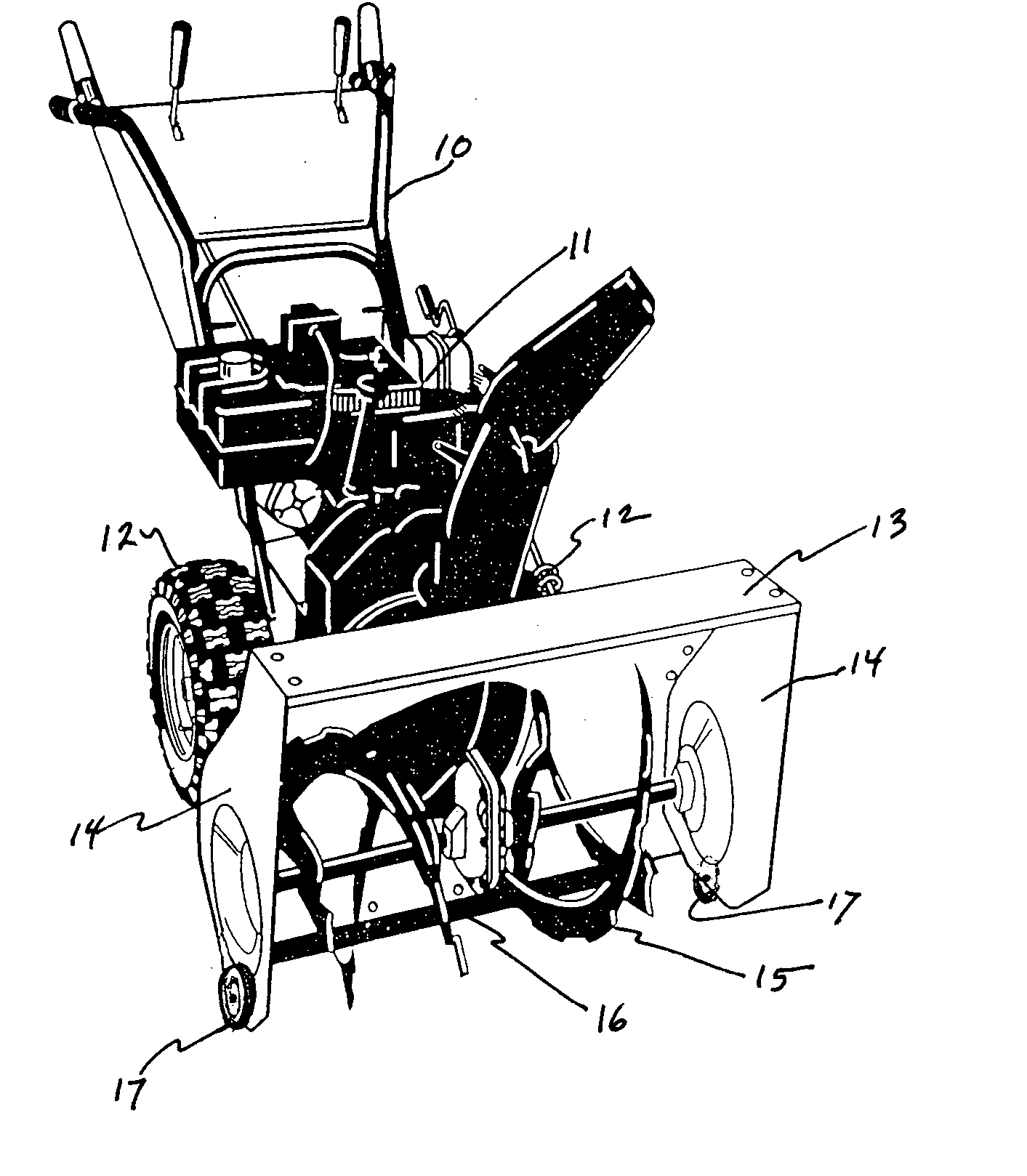

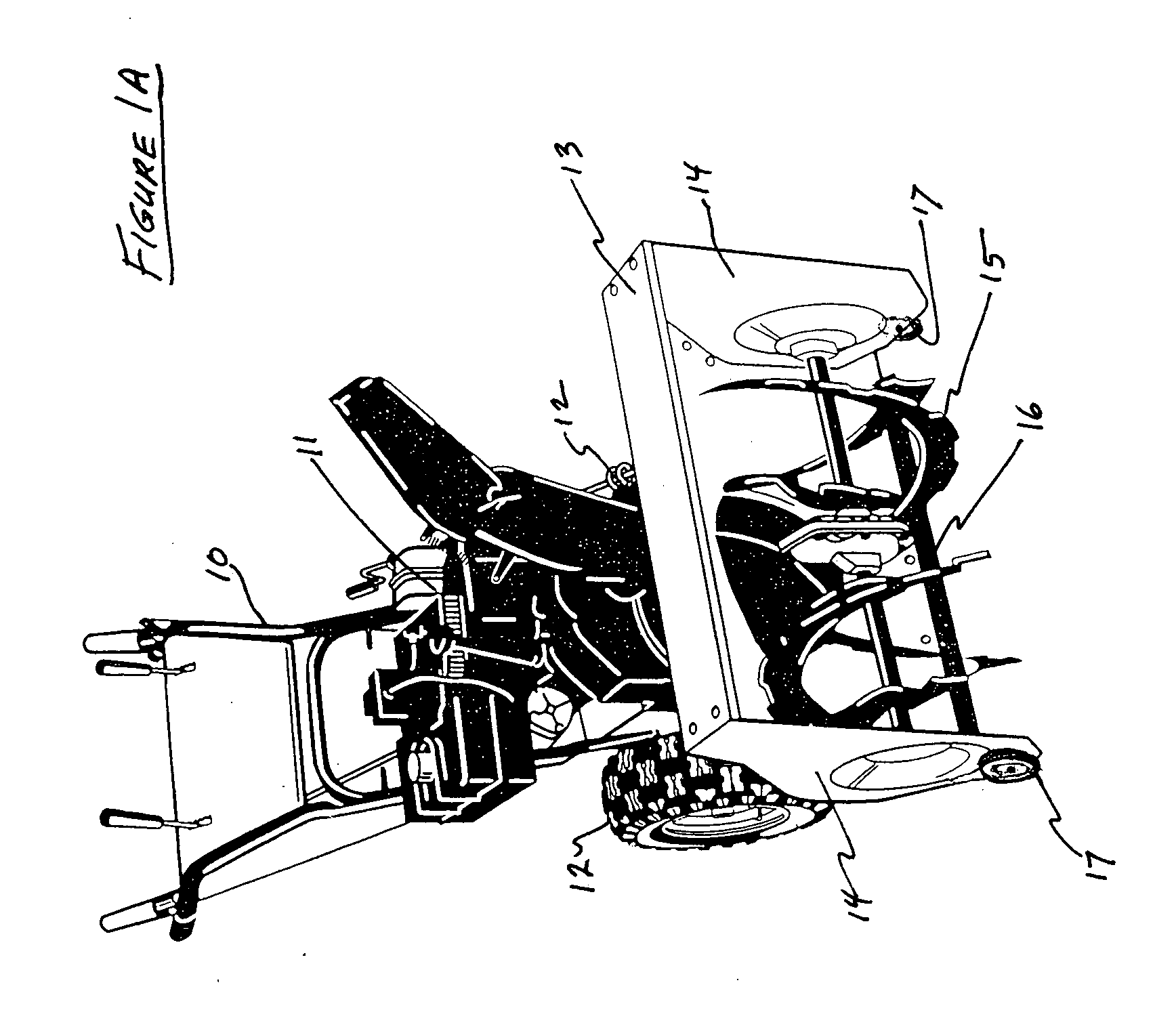

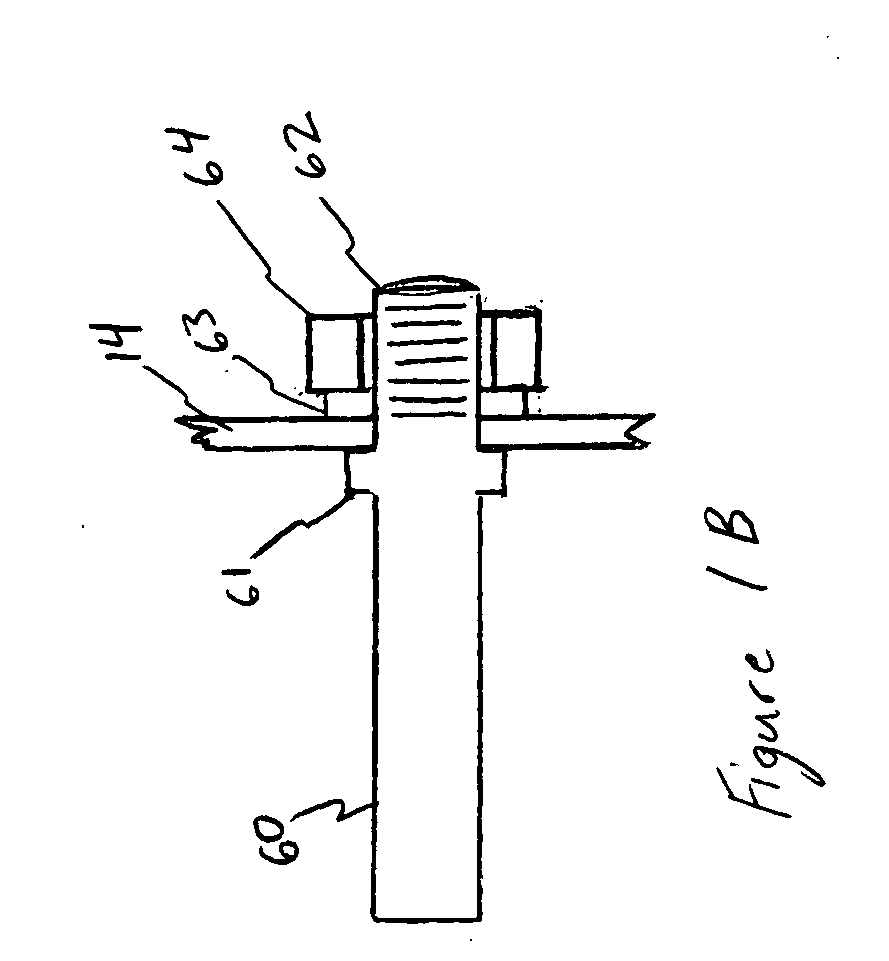

[0021] The subject disclosure relates to glide wheels to support the auger housing of a snow blower and to provide for clearance between the scraper blade and the surface to be cleared of snow. The glide wheels may be attached directly to the side walls of the auger housing, or, alternatively, the glide wheels may be part of a glide wheel assembly and means for adjustably supporting a front assembly of power driven equipment. The device and method are particularly applicable for use in snow removing equipment configured for stand-behind operation having an engine situated above two drive wheels and an attached front-mounted auger, although they may be utilized in many other applications to replace skid shoes as a means of support for other types of power equipment, as would be readily appreciated by those skilled in the pertinent art. The advantages and other features of the device and method disclosed herein will become more readily apparent to those skilled in the pertinent art fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com