Monolithic semiconductor laser and method of manufacturing the same

a semiconductor laser and monolithic technology, applied in the direction of semiconductor lasers, semiconductor laser arrangements, active medium materials, etc., can solve the problems of increasing manufacturing costs and complex assembly steps, and achieve the effect of increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0019] Embodiment 1

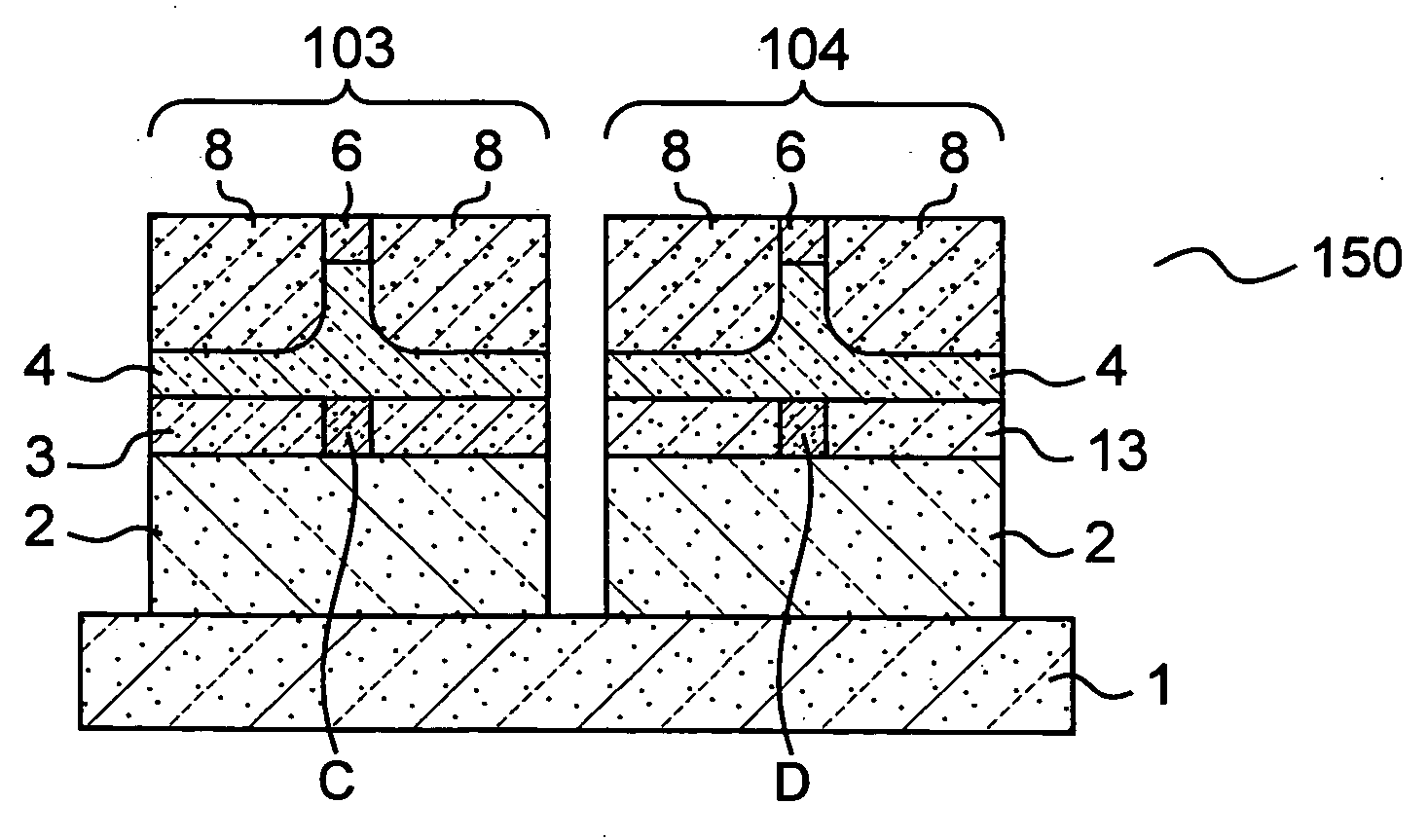

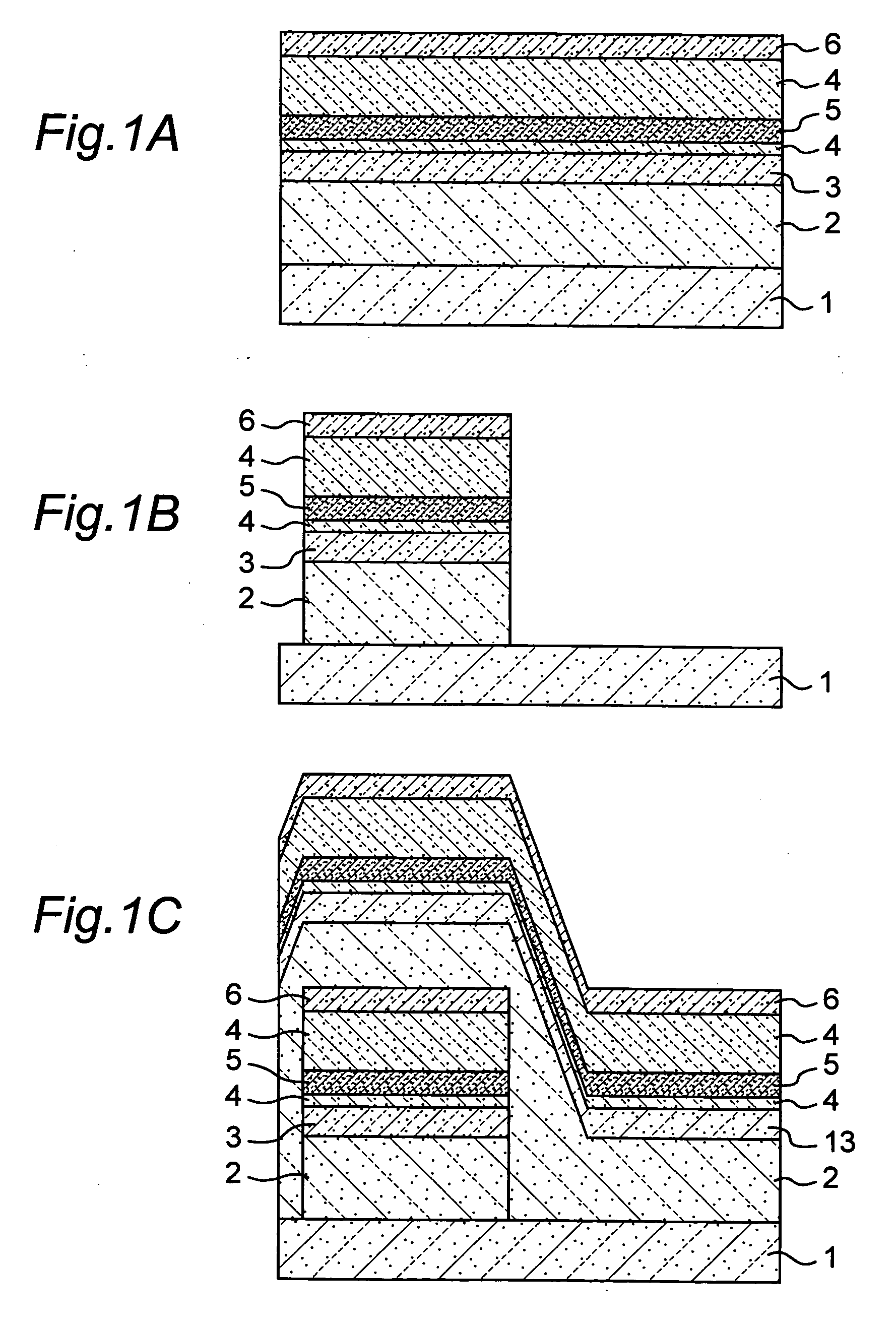

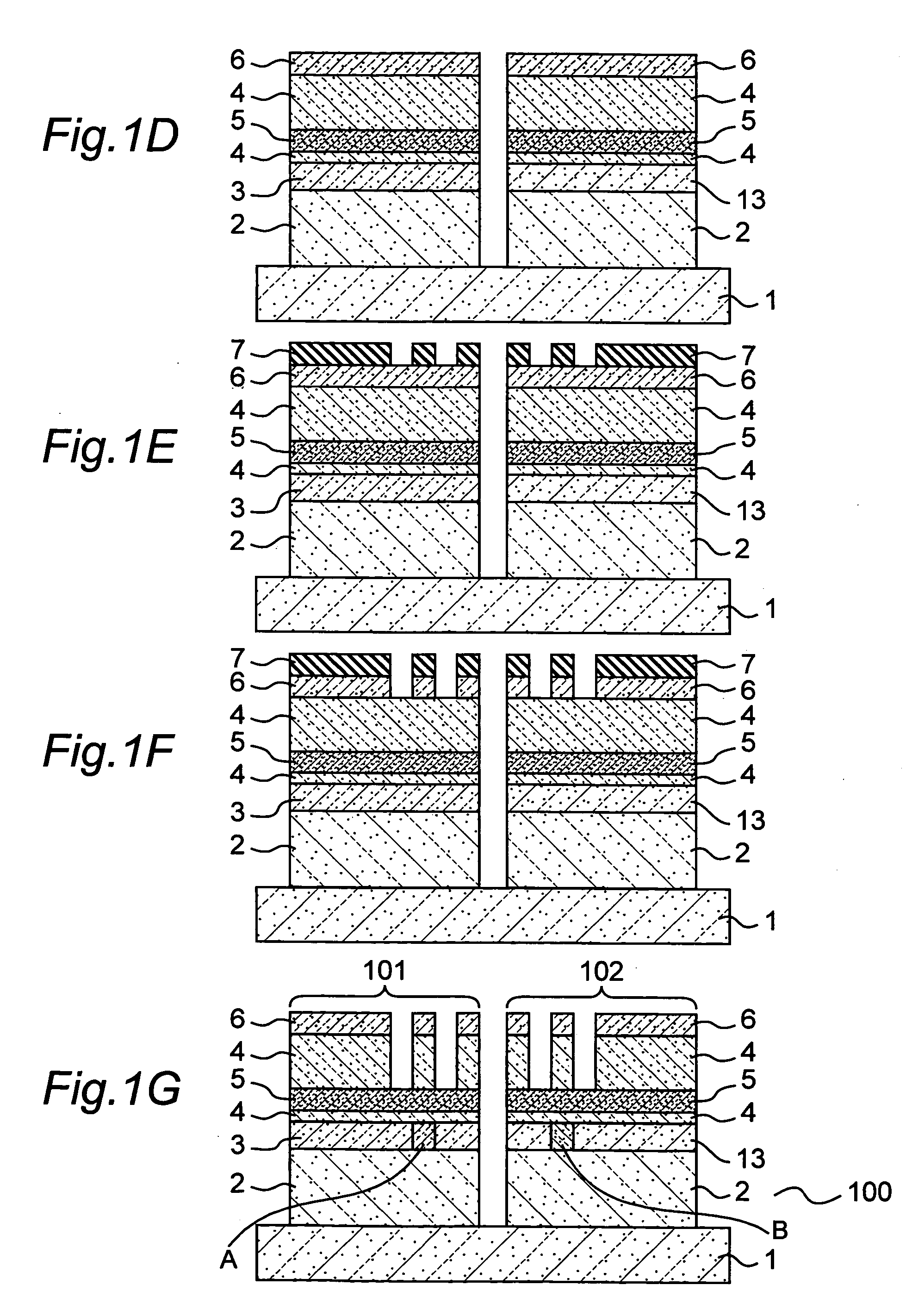

[0020]FIGS. 1A-1G are cross sectional views of steps of manufacturing a monolithic semiconductor laser according to this embodiment which is generally denoted at 100. The monolithic semiconductor laser 100 has a first semiconductor laser whose emission wavelength is 780 nm and a second semiconductor laser whose emission wavelength is 650 nm (See FIG. 1G).

[0021] The steps of manufacturing the monolithic semiconductor laser 100 will now be described with reference to FIGS. 1A-1G. These steps include the following steps 1 through 7.

[0022] Step 1: As shown in FIG. 1A, a GaAs substrate 1 of the n-type is prepared. On the GaAs substrate 1, an n-AlGaInP lower clad layer 2, an AlGaAs active layer (having the emission wavelength of 780 nm) 3 and a p-AlGaInP upper clad layer 4 are then stacked one atop the other. A GaInP etching stopper layer 5 is inserted in the p-AlGaInP upper clad layer 4. Further, on the p-AlGaInP upper clad layer 4, a p-GaAs cap layer 6 is formed.

[0...

embodiment 2

[0049] Embodiment 2

[0050]FIGS. 2A-2C show cross sectional views of steps of manufacturing a monolithic semiconductor laser according to this embodiment which is generally denoted at 200. The monolithic semiconductor laser 200 has two semiconductor lasers 201 and 202 which have different emission wavelengths (The emission wavelengths are 780 nm and 650 nm for example.) (FIG. 2C).

[0051] In the monolithic semiconductor laser 200 according to the embodiment 2, the compositions and the like of other layers than active layers are different between the two semiconductor lasers 201 and 202. Use of stopper layers makes it possible to etch at a high accuracy also in these structures.

[0052] Through approximately the same steps (FIGS. 1A-1D) as those exercised in the embodiment 1 described above, a stacked structure as that shown in FIG. 2A is fabricated on an n-GaAs substrate 1.

[0053] As the first semiconductor laser, on the n-GaAs substrate 1, an n-AlGaInP lower clad layer 21, an AlGaAs ac...

embodiment 3

[0068] Embodiment 3

[0069]FIGS. 3A-3C show cross sectional views of steps of manufacturing a monolithic semiconductor laser according to this embodiment which is generally denoted at 300. The monolithic semiconductor laser 300 comprises two semiconductor lasers 301 and 302 which have different emission wavelengths (The emission wavelengths are 780 nm and 650 nm for example.) (FIG. 3C).

[0070] In the monolithic semiconductor laser 300, ridge-type stripes are formed so that the ridge-type stripes have different depths between the two semiconductor lasers 301 and 302, and the refractive indices of the ridge-type stripes are adjusted.

[0071] In the monolithic semiconductor laser 300, first, through approximately the same steps (FIGS. 1A-1D) as those exercised in the embodiment 1 described earlier, a stacked structure as that shown in FIG. 3A is fabricated on an n-GaAs substrate 1.

[0072] As the first semiconductor laser, on the n-GaAs substrate 1, an n-AlGaInP lower clad layer 41, an AlG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com