Inline stacker with non-interrupt gap generator and integrated drive control and jam response

a gap generator and stacker technology, applied in the direction of thin material processing, article delivery, transportation and packaging, etc., can solve the problems of insufficient reliability of encoder signal, increased jamming, and easy jamming of encoder signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

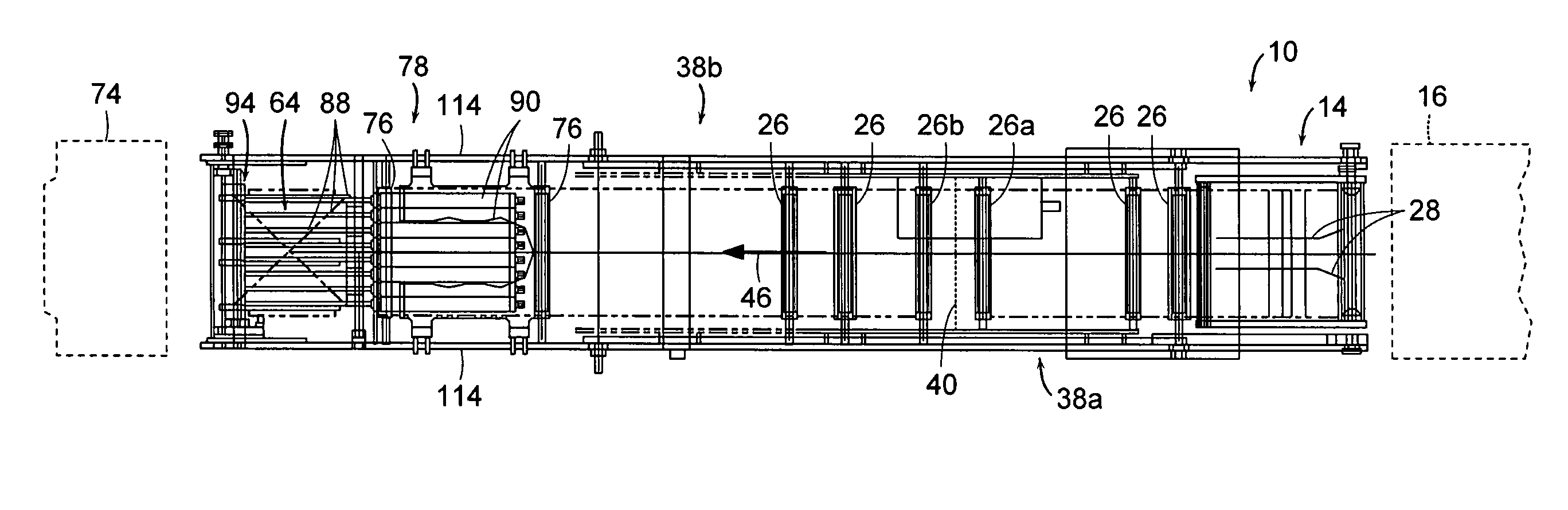

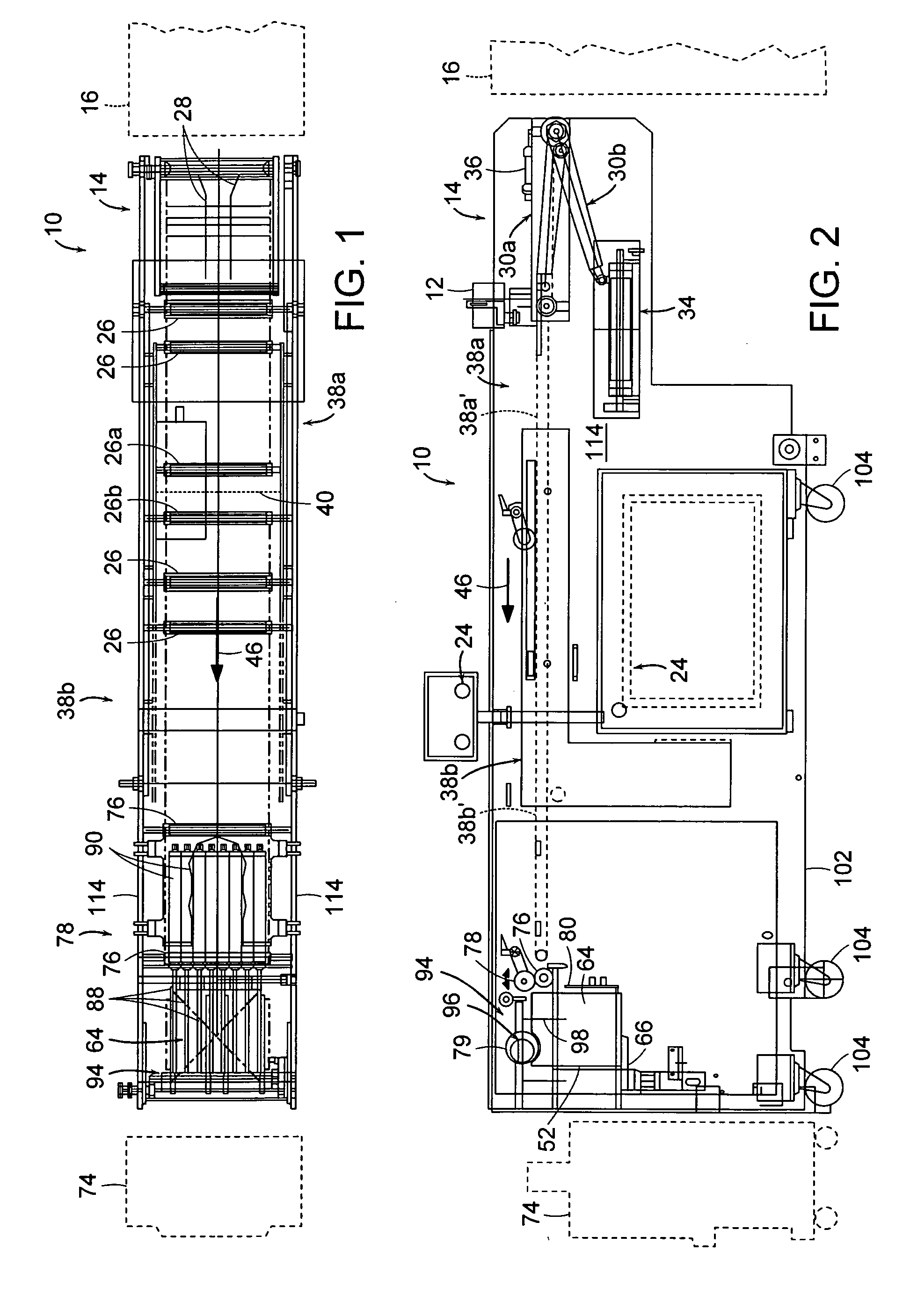

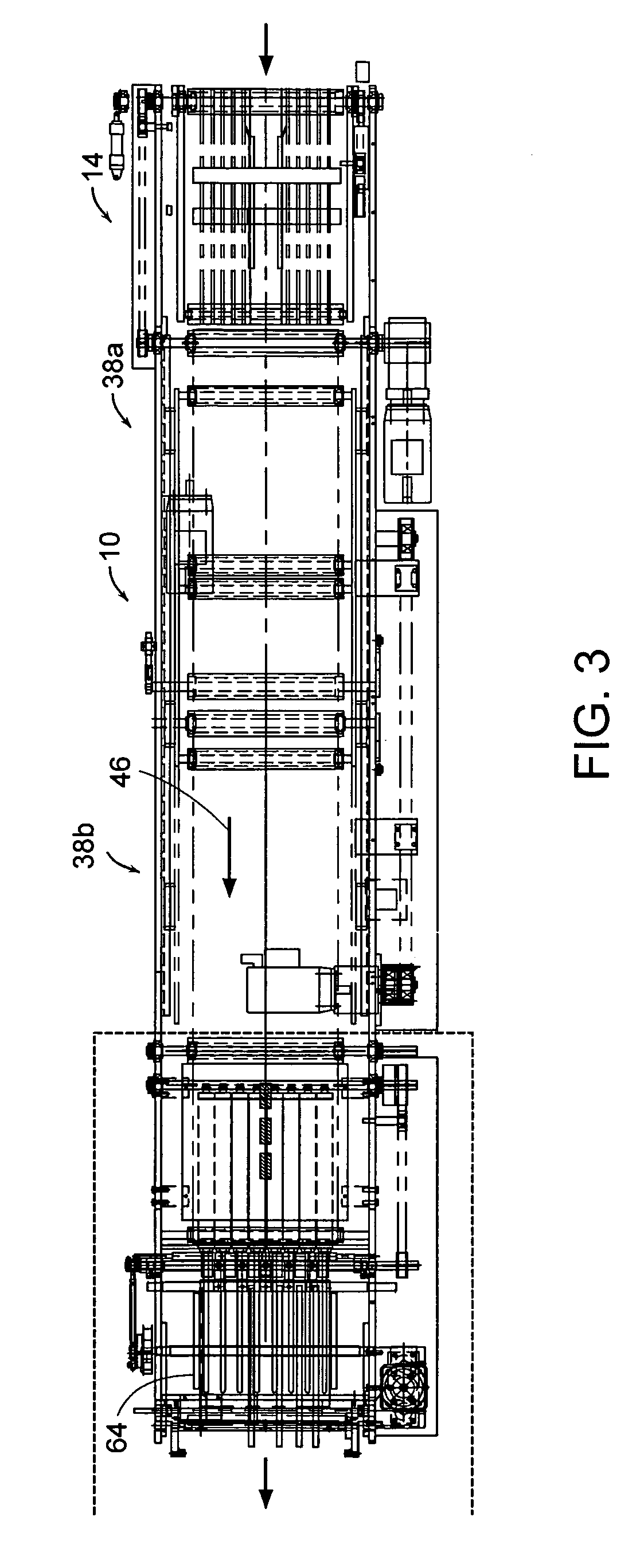

[0034] With reference to FIGS. 1-16, the stacker 10 of the present invention has various features that alone, or in combination, solve various problems, such as those discussed above, that have plagued the known stackers. A principal feature is that the control of the stacker speed and stacking operations originates with a sheet counter 12 located at a stacker infeed section 14. The counter 12 sets the speed of the stacker to match the output of the equipment 16 which feeds the stacker. For the purposes of this description, this in-line equipment operating a succession of flat sheet products to be stacked will be described as a printing press and the products as printed paper sheets, including folder sheets such as signatures. The counter 12 also controls the operation of a gap generator 18 of the stacker 10 to produce a gap in an infeed shingled stream 20 of products 22. The gap in the shingled stream is created after a predetermined number of the products has been detected by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com