Low temperature sintering of nickel ferrite powders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Example 1 Comparative

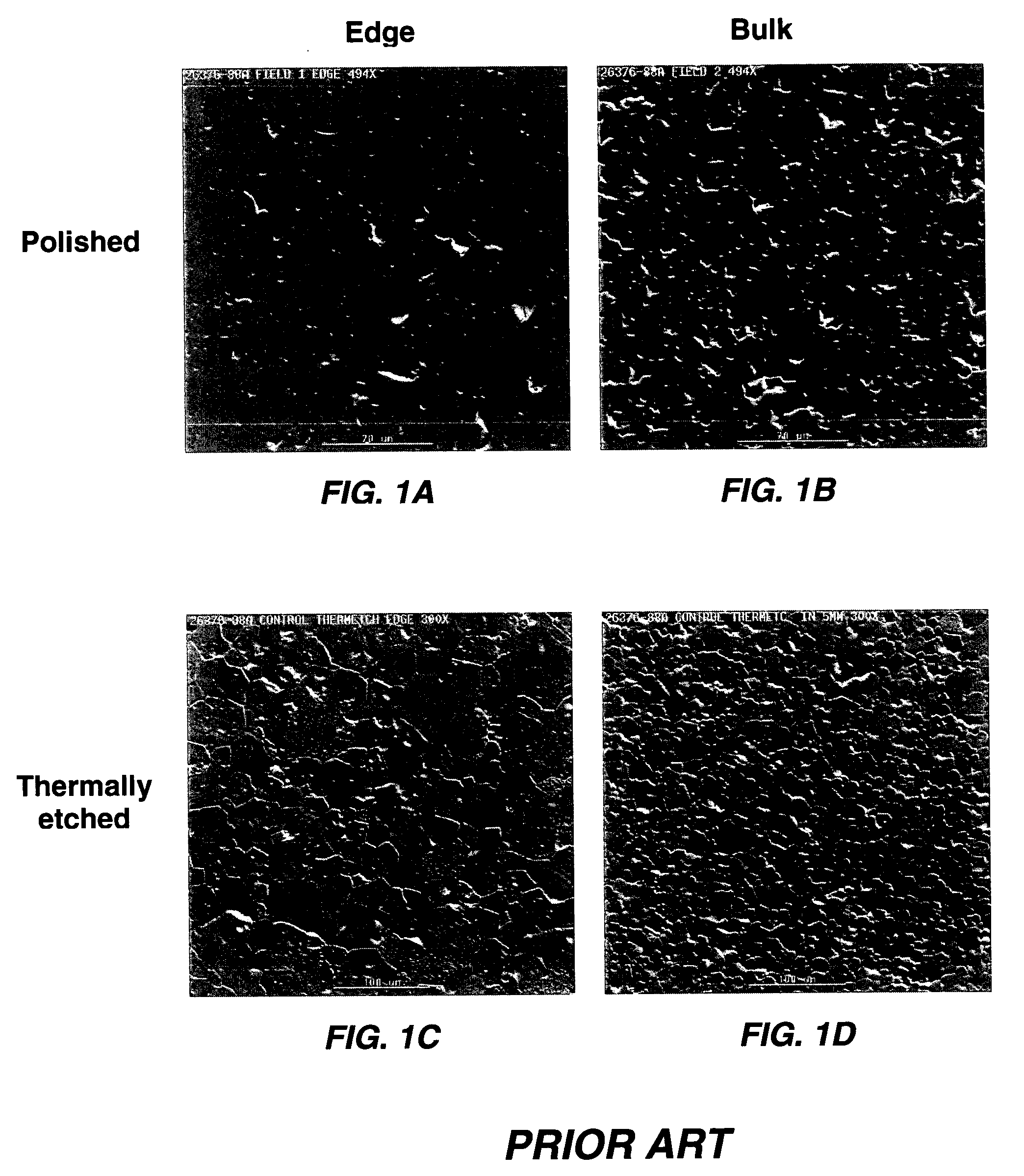

[0022] A mixture containing 68.2 wt. % Fe2O3, 29.8 wt. % NiO and 2 wt. % mixture of polyethylene glycol (PEG) and polyvinyl alcohol (PVA) binders was pressed into a compact and sintered in air at 1500° C. for two hours. FIGS. 1A and 1B are photomicrographs of the resultant component after polishing near its edge and in the bulk of the component, respectively. FIGS. 1C and 1D are photomicrographs of the component after thermal etching near the edge and in the bulk, respectively. It can be seen that away from the edge area, the grain sizes are significantly reduced with increased quantity of grain boundaries.

Example

Example 2

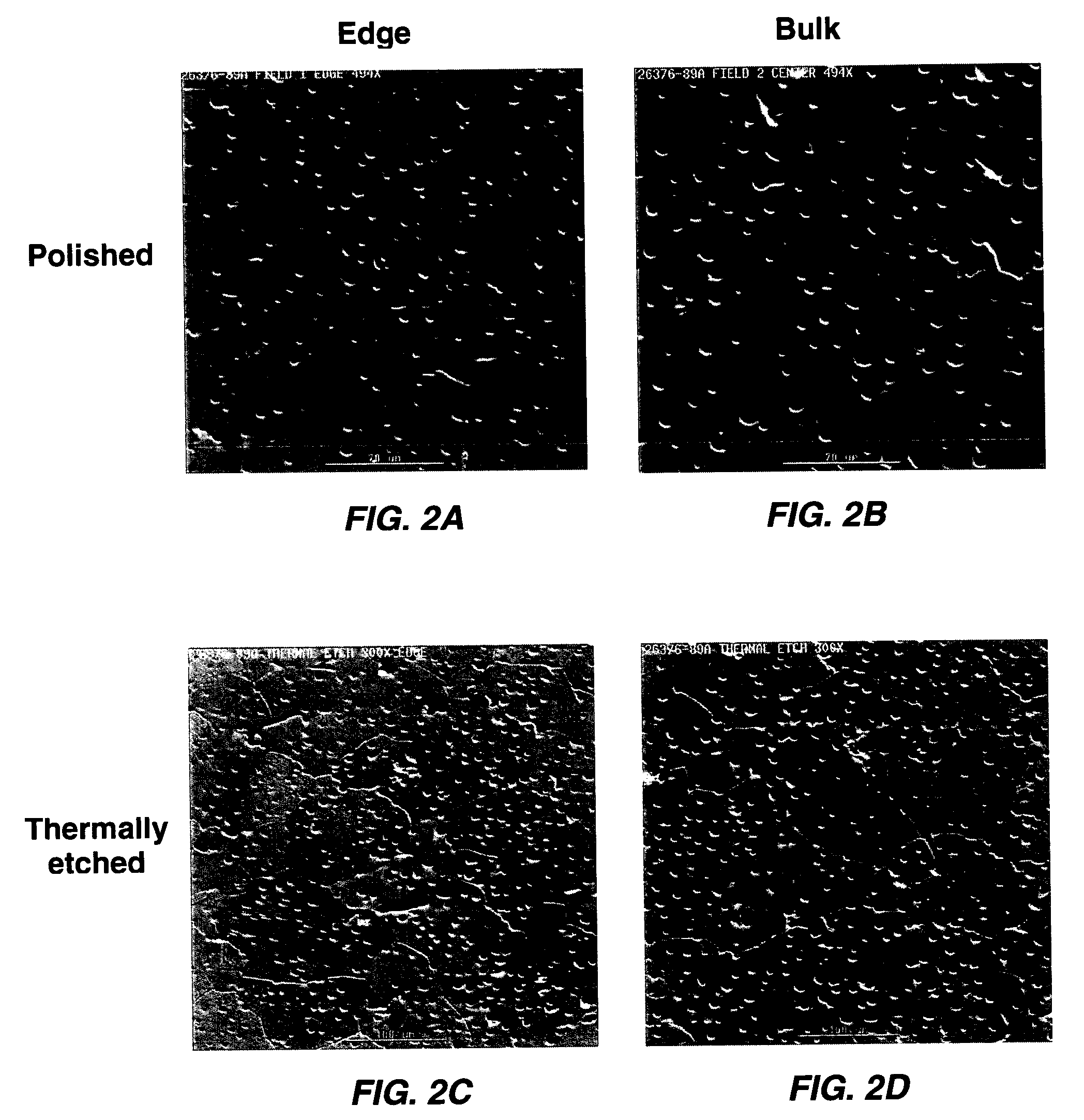

[0023] A mixture of 68.2 wt. % Fe2O3, 29.8 wt. % NiO, 2 wt. % mixture of PEG and PVA binders and 0.045 wt. % boron from lithium borate were pressed into a die to produce a green compact. The compact was sintered in air at 1200° C. for two hours. FIGS. 2A and 2B are photomicrographs of the resultant component as polished in the edge area and in the bulk of the component, respectively. FIGS. 2C and 2D are photomicrographs of the component after thermal etching near the edge and in the bulk, respectively. It can be seen that the quantity of grain boundaries does not increase within the bulk of the component from the edge area and that the grain sizes are larger and more uniform than those produced in Example 1.

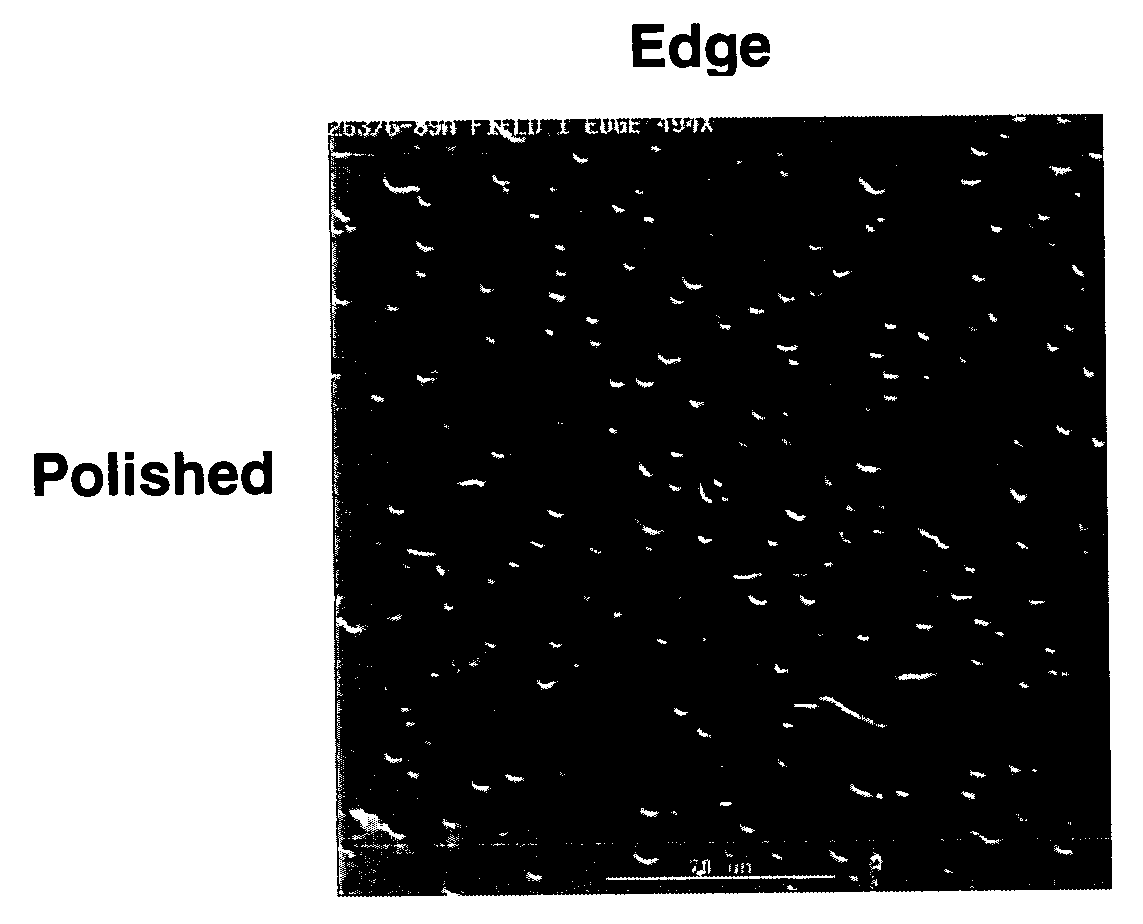

[0024] Example 2 was repeated except that sodium borate was used in place of lithium borate. FIGS. 3A and 3B are photomicrographs of the resultant component as polished in the edge area and in the bulk of the component, respectively. FIGS. 3C and 3D are photomicrograph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com