Wavefront characterization of corneas

a wavefront and corneal technology, applied in the field of wavefront sensing, can solve the problems of inability to conclusively tell, either visually or under a microscope, and the cornea is generally unsuitable for corneal transplantation, and achieves scintillation and static aberration, aberrations that produce scintillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

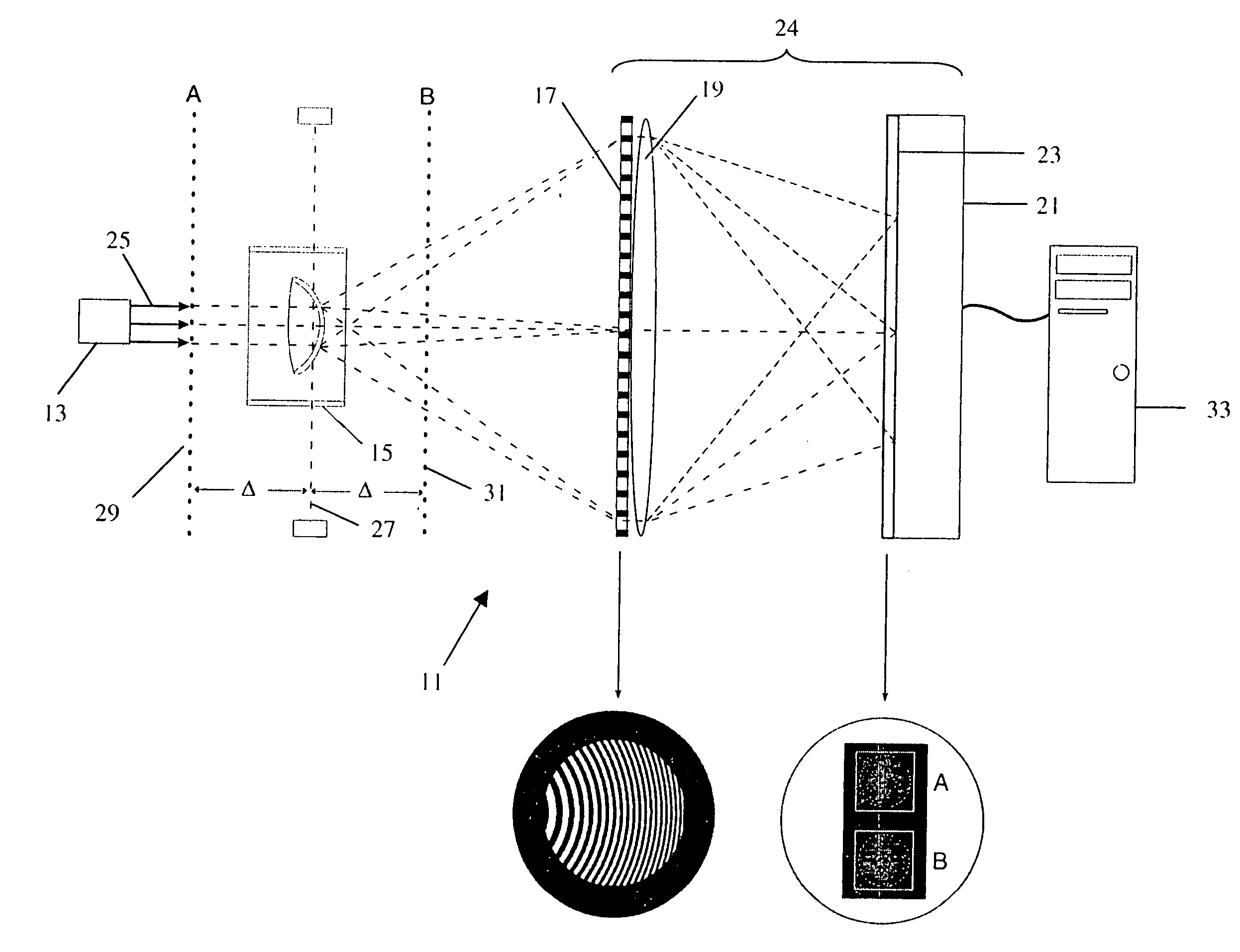

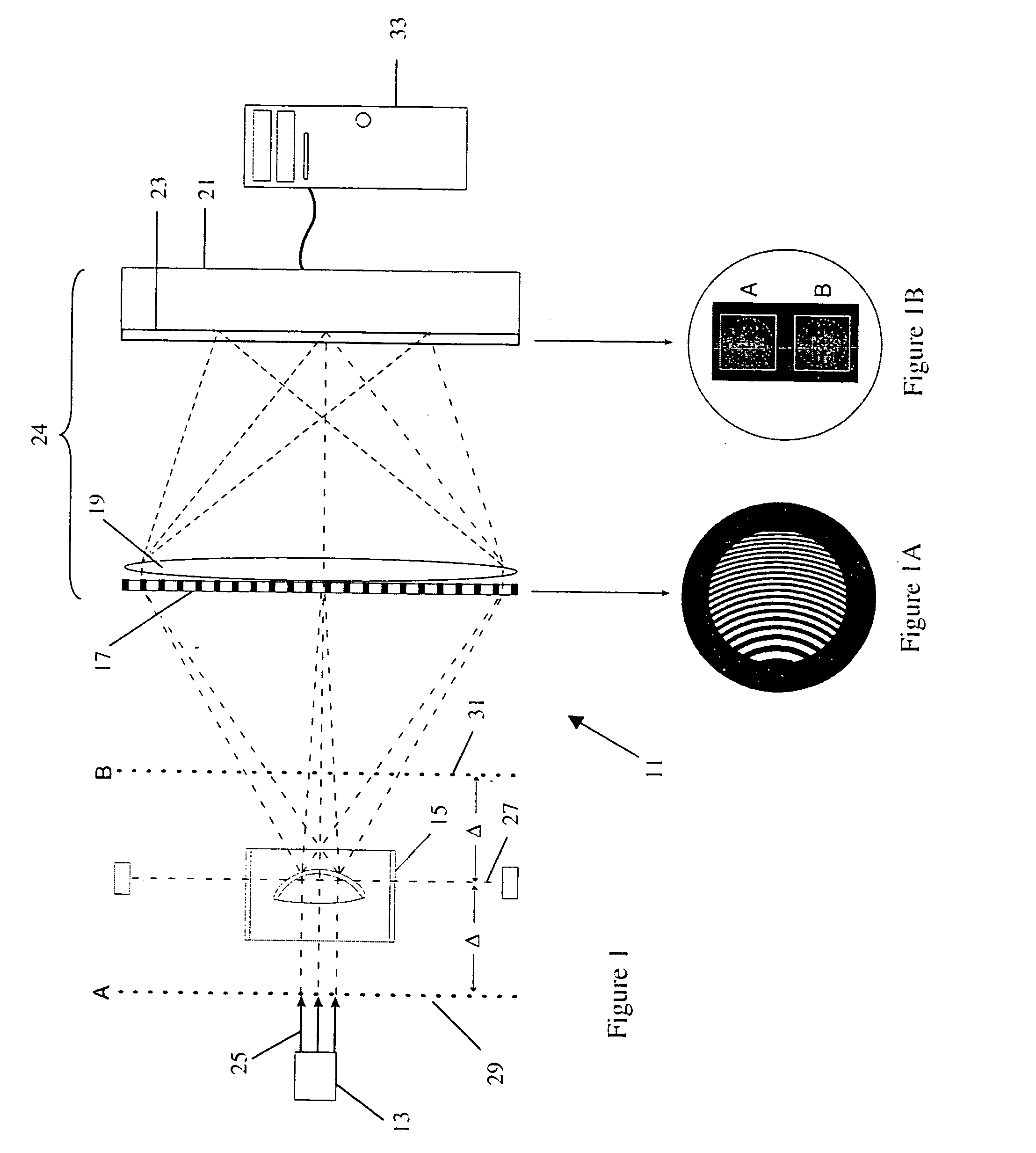

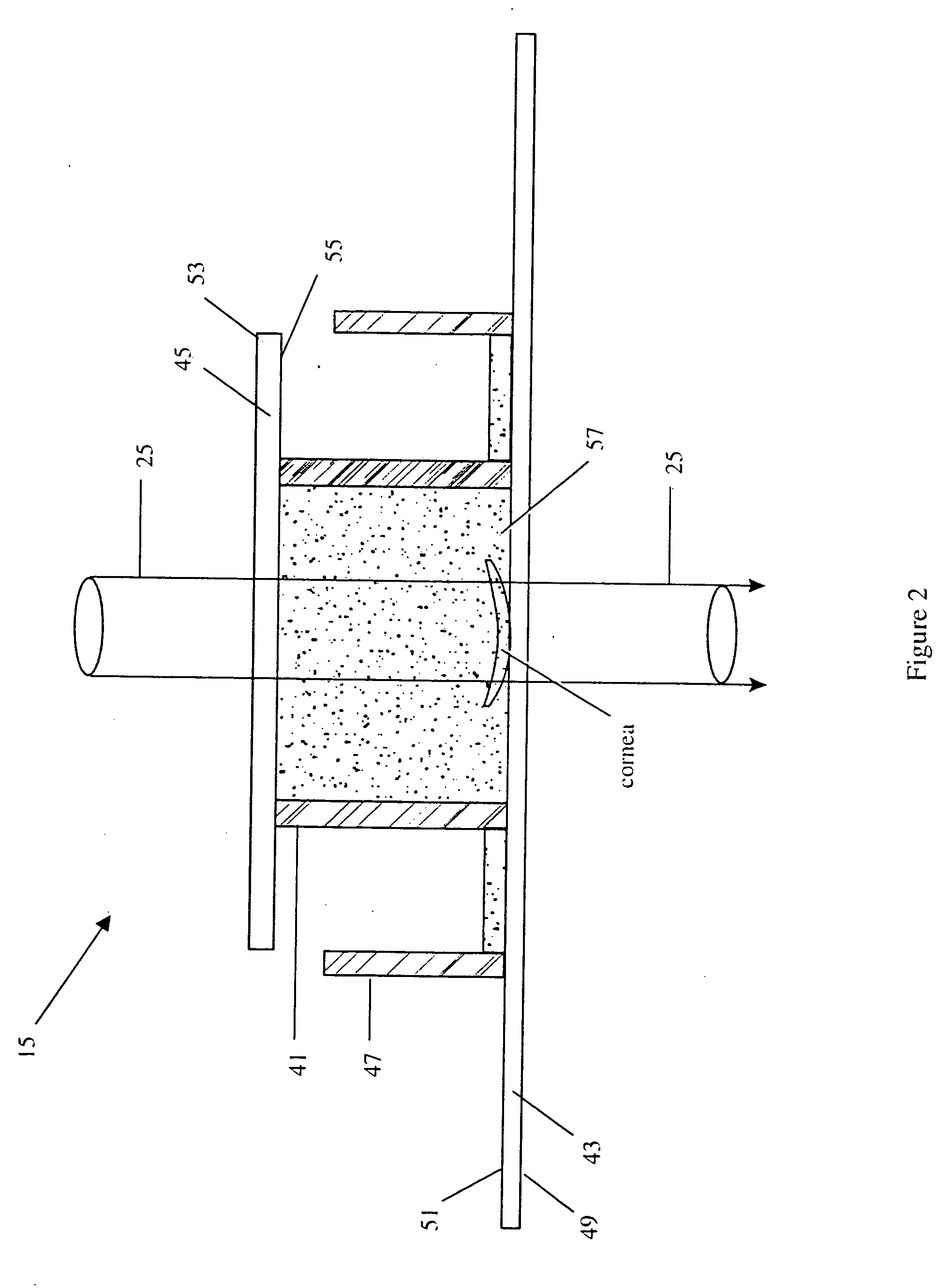

[0040] With reference to FIG. 1, the apparatus 11 for determining whether an in vitro cornea has been modified (either surgically or otherwise) includes a source of collimated coherent light 13, a cornea container 15, a distorted diffraction grating 17, a high quality imaging lens (or lens set) 19, and a detector 21 (either film or electronic) having a detector plane 23. (Grating 17, lens 19 and detector 21 are sometimes referred to as wavefront sensor 24.) Apparatus 11 also includes a beam path 25, a pupil plane 27, first virtual plane 29, second virtual plane 31, and a computer 33. Computer 33 is connected to detector 21, via a data acquisition device such as a frame grabber (located within the computer housing). Computer 33 stores the images form detector 21, determines the wavefront from the stored images, and the analyzes the wavefront for the characteristics that identify an altered cornea (e.g. compares the wavefronts to a stored norm). The representation of the virtual plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com