High flow rate fuel valve and fuel supply pump with the valve

a high flow rate, fuel valve technology, applied in the direction of pump control, fuel injection apparatus, charge feed system, etc., can solve the problems of large amount of fuel not being pressurized sufficiently, complex accumulation fuel injection device, etc., to achieve easy pressurization, easy to prevent generation of erosion, and easy to raise combustion efficiency in the fuel injection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

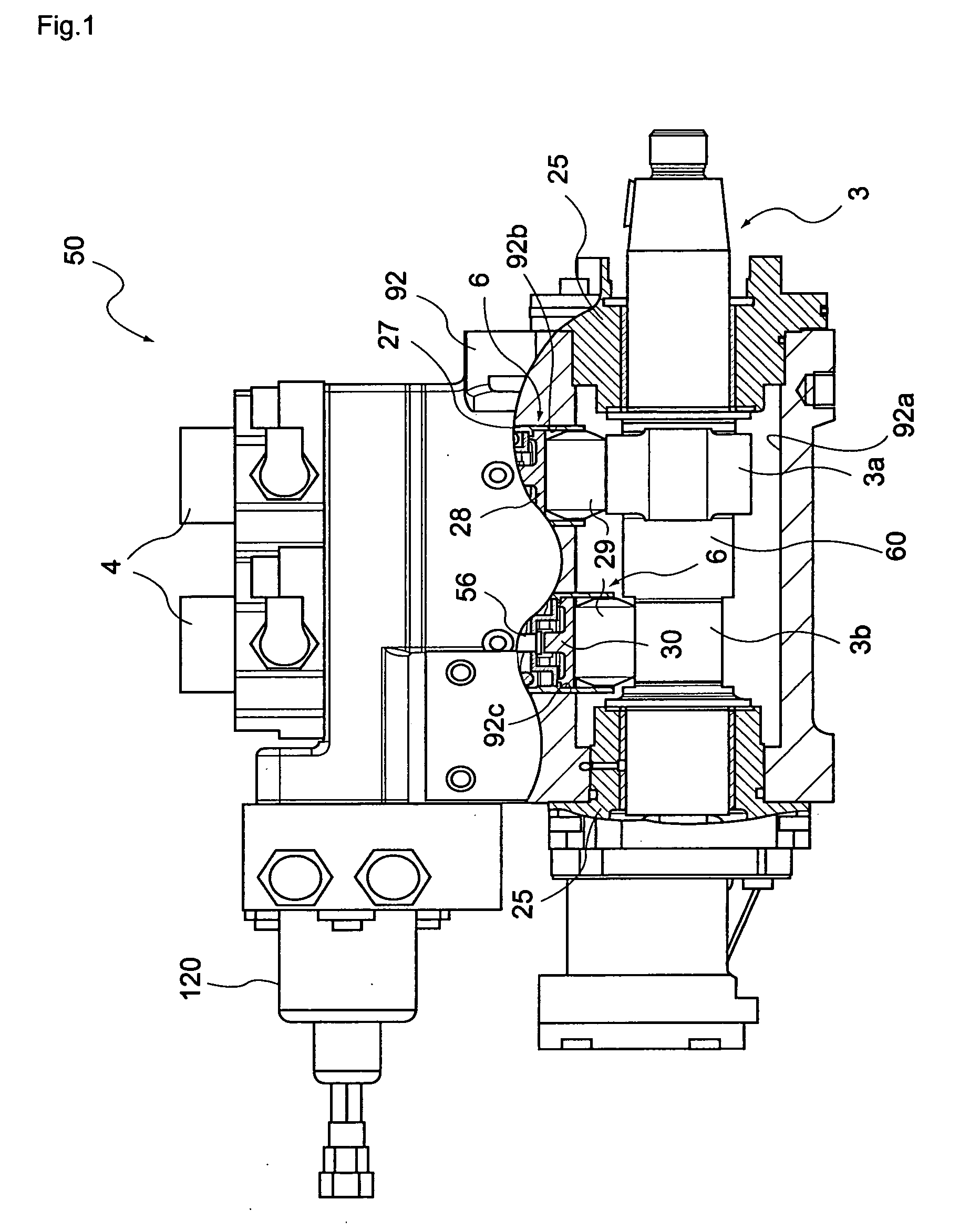

[0052] As illustrated in (a) and (b) of FIG. 1, a first embodiment of the present invention is a high flow fuel valve 73 that comprises a valve main body 19, a valve body 20 movably installed in the inside of the valve main body 19, an inlet chamber 19a formed in the inside of the valve main body 19, inlet holes 19c, and a seat portion 23 where part of the valve body 20 and part of the valve main body 19 are contact with each other. The high flow fuel valve 73 is characterized in that a plurality of inlet holes 19c is formed and these inlet holes 19c are arranged in a non-radical pattern relative to the inlet chamber 19a.

[0053] Hereinafter, the high flow fuel valve 73 will be described more concretely by way of individually describing its structural components.

1. Valve Main Body

[0054] A valve main body is not specifically limited to a certain configuration as far as it retains a valve body and performs a predetermined movement. Preferably, however, the valve main body may be in ...

second embodiment

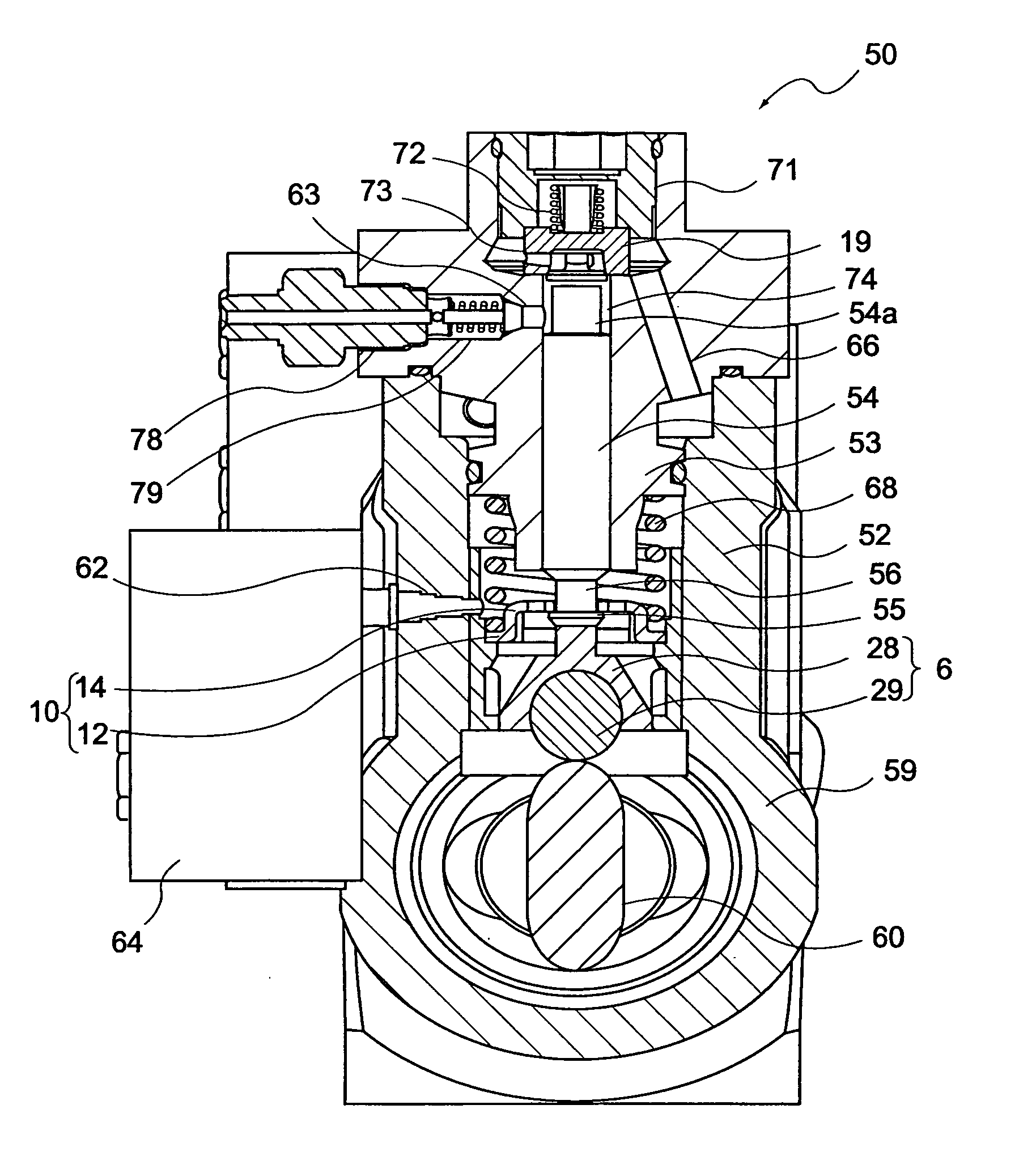

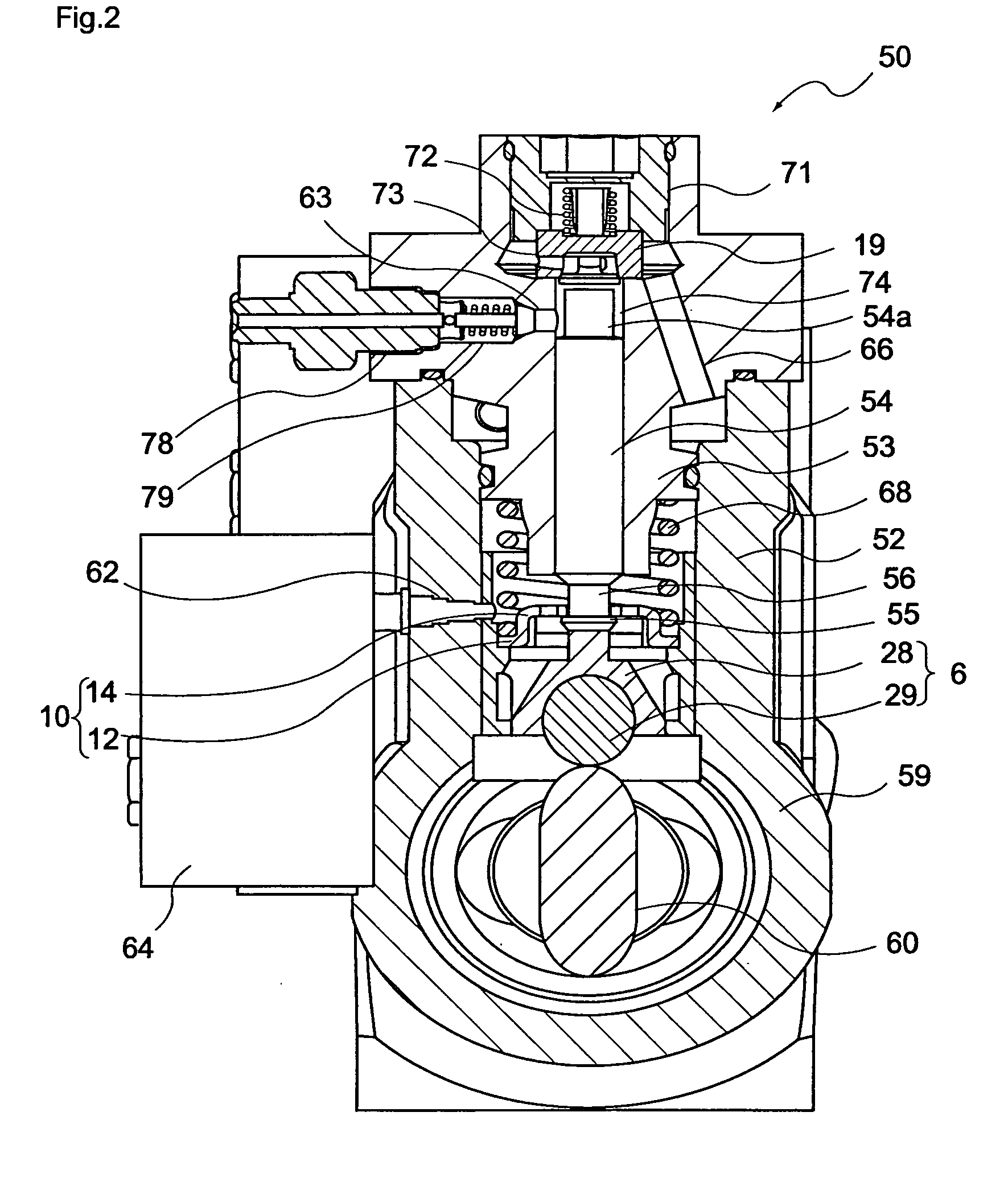

[0102] As shown in FIG. 13, a second embodiment of the present invention is a fuel supply pump 50 having a fuel inlet valve 73 and a fuel outlet valve 19 and is characterized by the following configuration. The fuel inlet valve 73 comprises a valve main body 19, a valve body 20 movably installed in the inside of the valve main body 19, an inlet chamber 19a formed in the inside of the valve main body 19, inlet holes 19c, a seat portion 23 where part of the valve body 20 and part of the valve main body 19 are contact with each other, wherein a plurality of inlet holes 19c is formed and these inlet holes 19c are arranged in a non-radical pattern.

[0103] Hereinafter, the fuel supply pump 50 will be described more concretely by way of individually describing its structural components.

1. Fuel Inlet Valve

[0104] The second embodiment is characterized in that a fuel inlet valve used is the high flow fuel valve described in the first embodiment. Thus, it is preferable to design an IO valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com