Vacuum lamination device and vacuum lamination method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

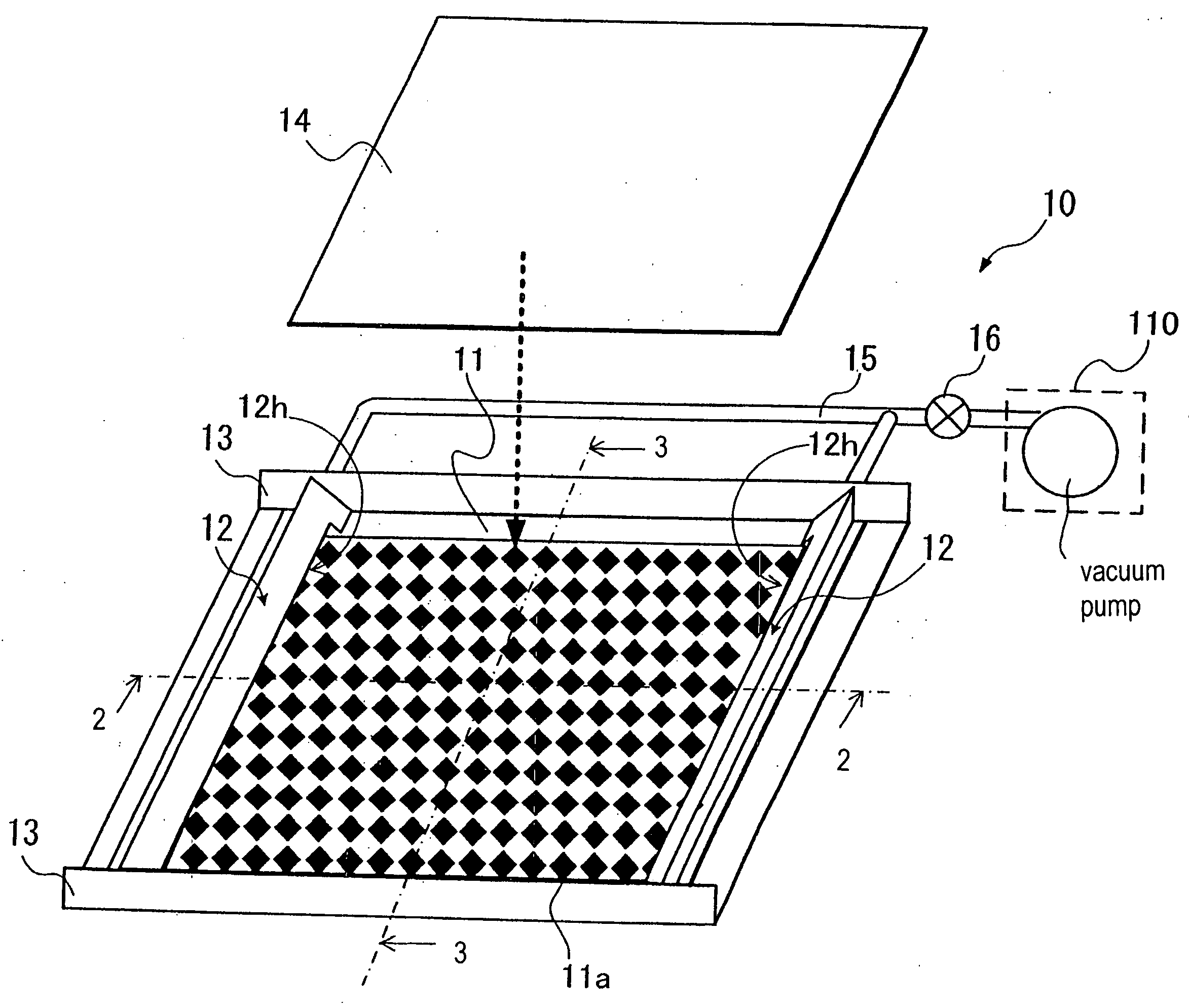

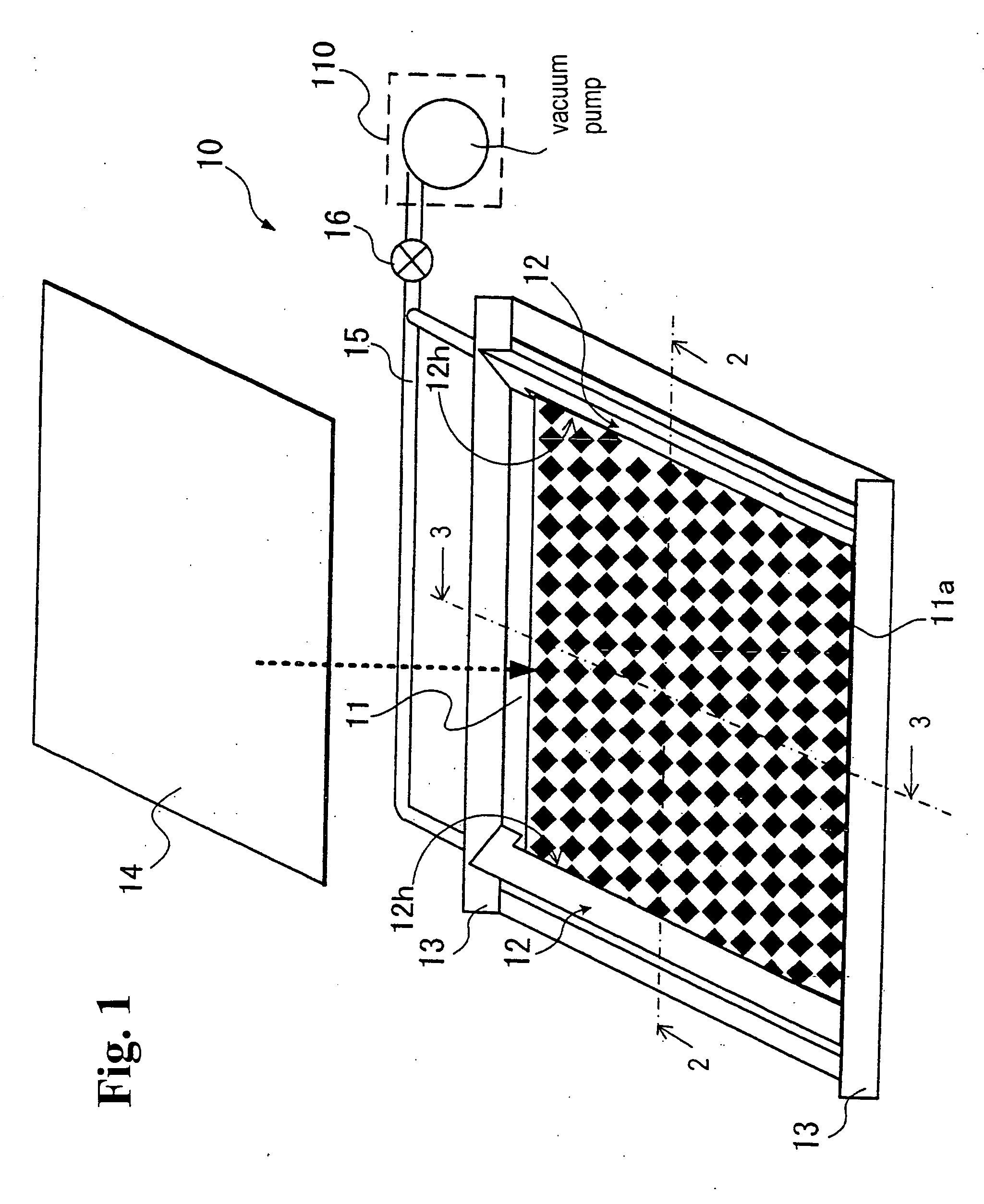

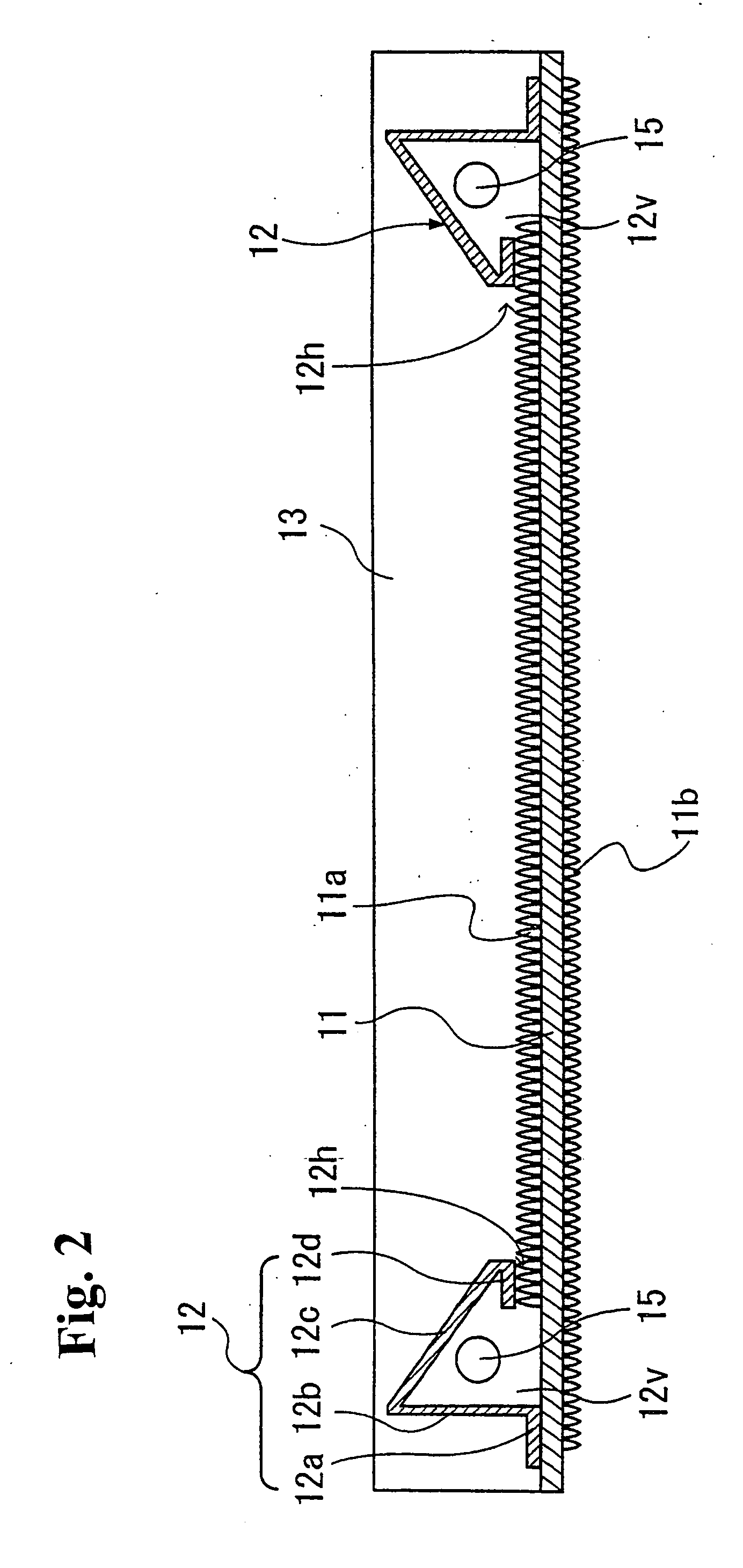

[0027] Hereunder, embodiments of the present invention will be explained in detail with reference to the accompanying drawings. FIG. 1 is a perspective view of a vacuum lamination device according to an embodiment of the present invention. FIG. 2 is a cross-sectional view taken along line 2-2 in FIG. 1. FIG. 3 is a cross-sectional view taken along line 3-3 in FIG. 1. According to an embodiment, a vacuum lamination device 10 includes a base plate 11 for placing a lamination member (referred to as a solar cell module) thereon; frame members 12 fixed on the base plate 11 and having discharge ports 12h for evacuating a processing space; plate members 13 fixed to end portions of the frame members 12 in a width direction; and a cover member 14 for hermetically sealing the processing space. The vacuum lamination device 10 further includes a discharge port 15 as a path for connecting the frame members 12 and a vacuum pump 110 through a valve 16.

[0028] The base plate 11 constitutes a bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com