Excavating lip-mounted adapter and associated connection and shielding apparatus

a technology of adapters and lip-mounted adapters, which is applied in the field of excavating apparatus, can solve the problems of undesirably reducing the efficiency of earth penetration, undesirably weakening the adapter/lip attachment strength, and undesirably subjecting to high tensile stresses, and achieves enhanced attachment strength, reduced overall height of the adapter, and strong weld joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

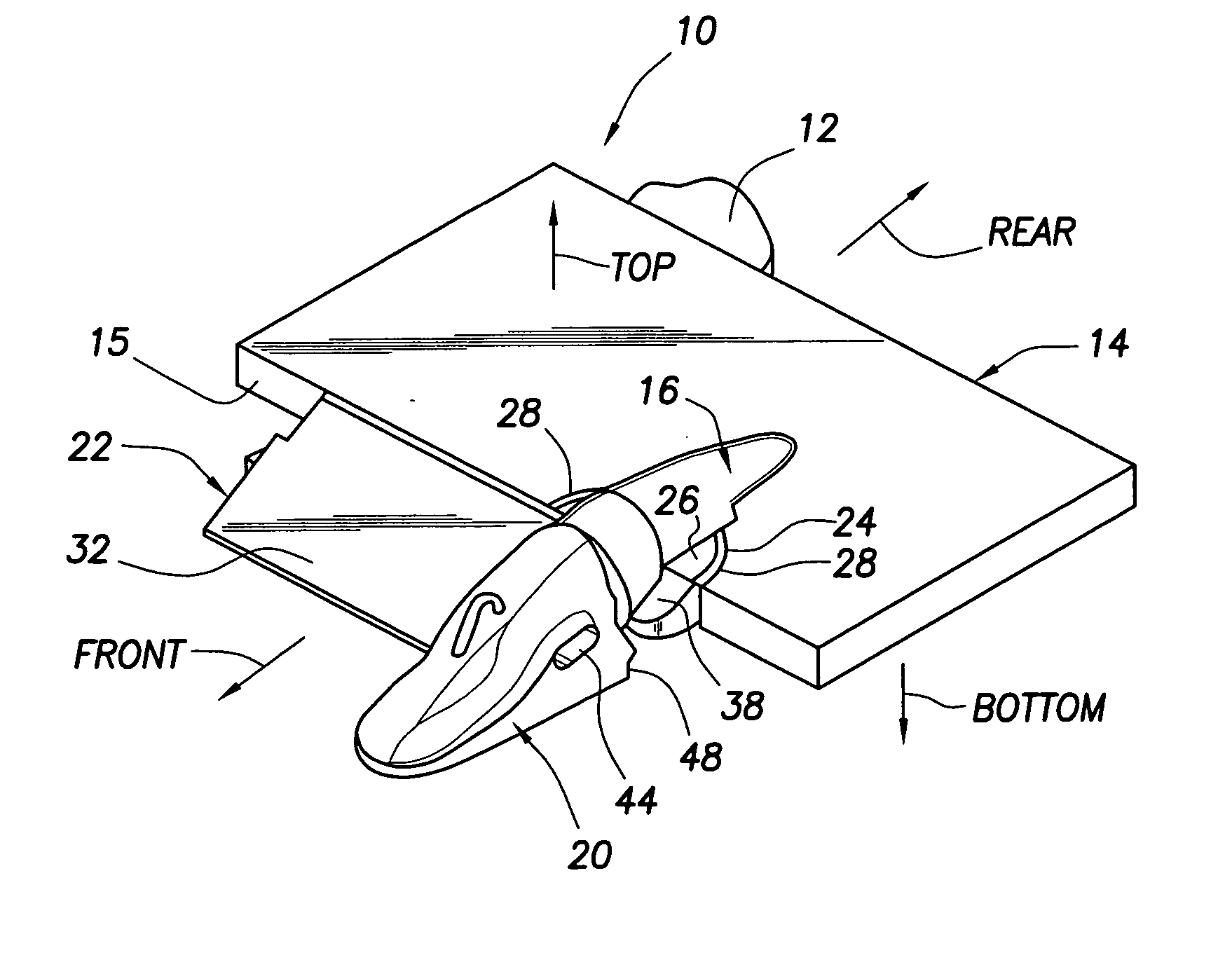

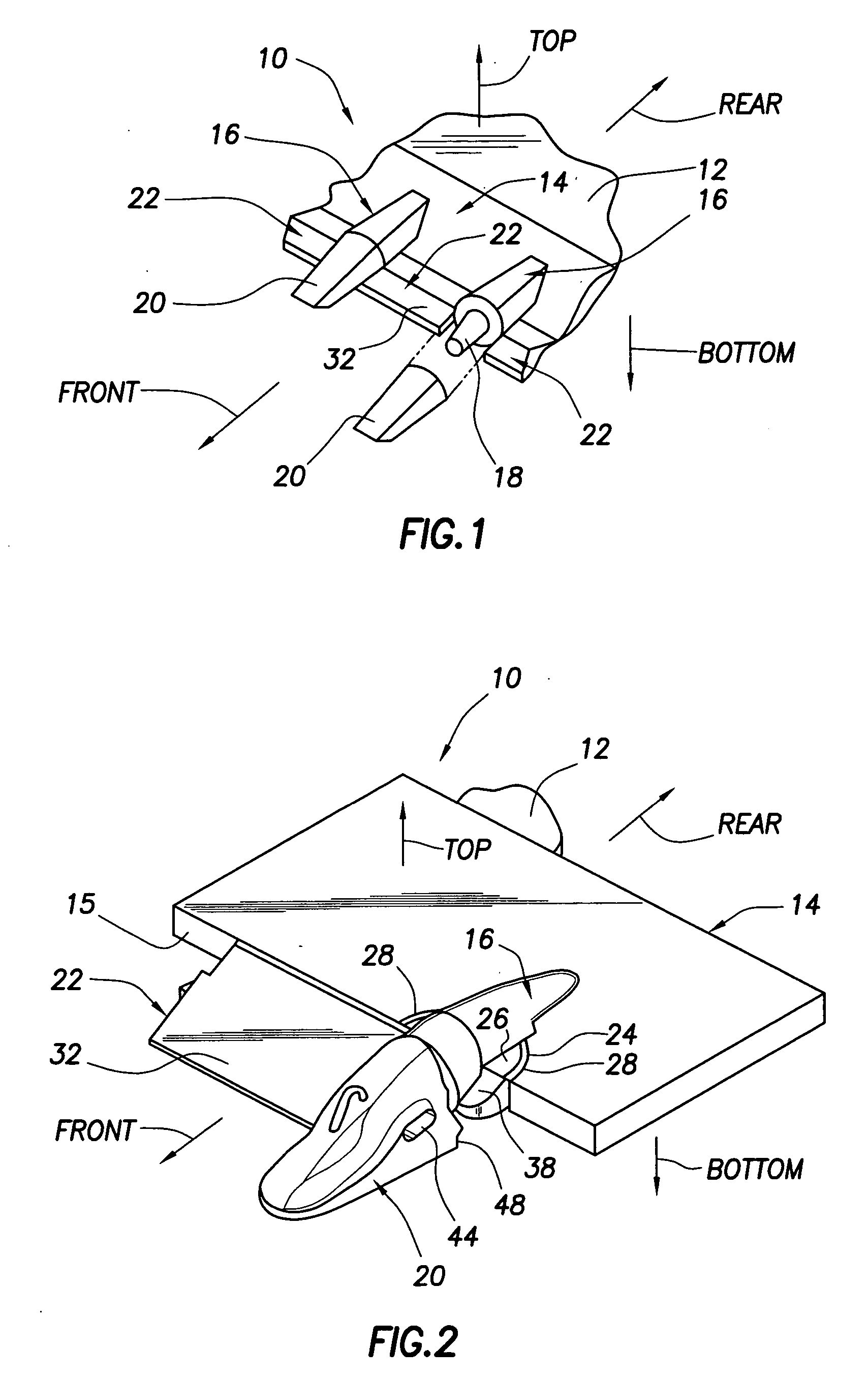

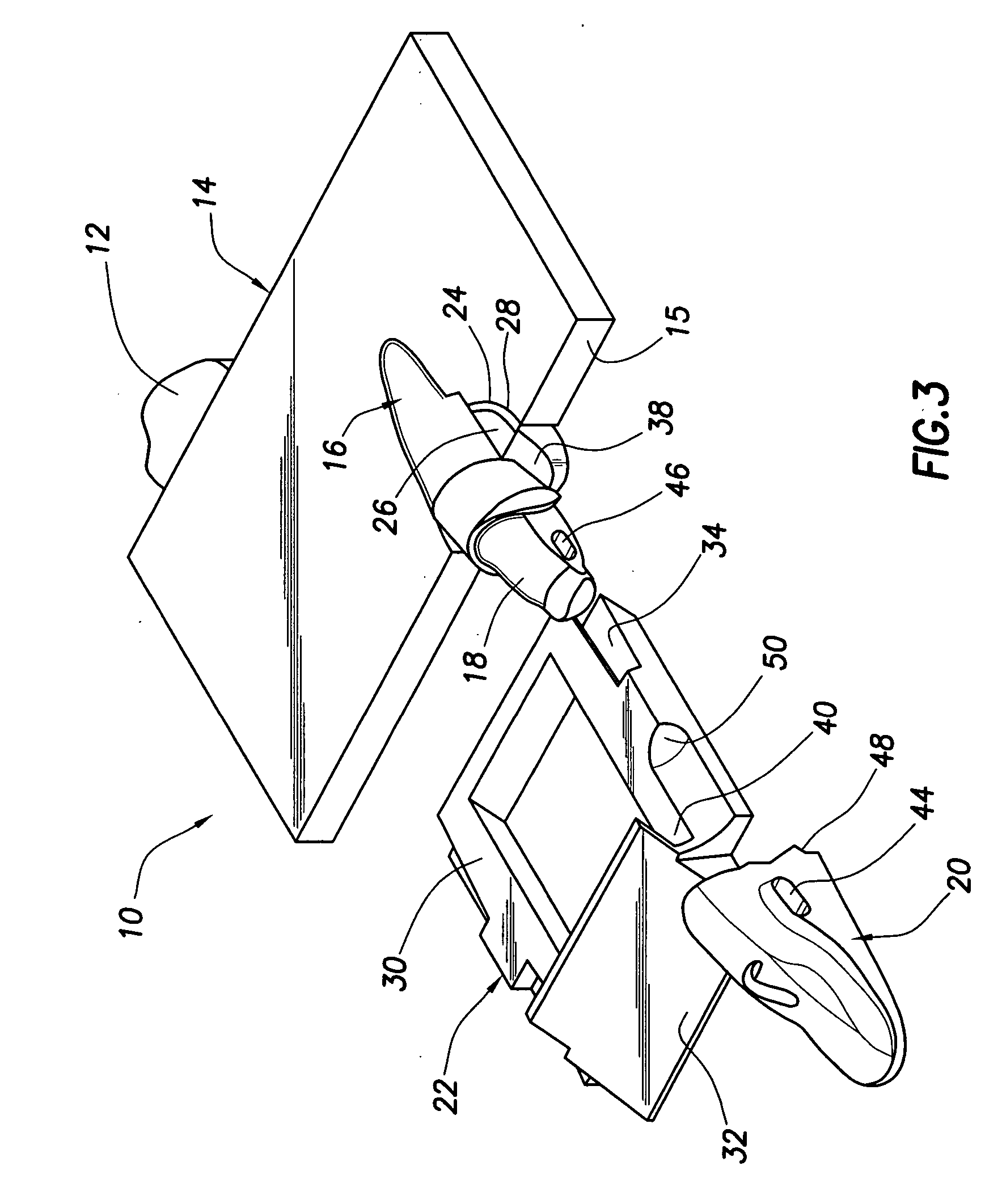

[0036] In one embodiment thereof, the present invention provides excavation apparatus representatively in the form of an excavating bucket 10, a portion of which is shown in simplified, partially exploded perspective form in FIG. 1. Bucket 10 has a bottom side wall 12 to a forward edge portion of which an elongated, plate-shaped blade or lip 14 is suitably anchored. As illustrated in FIG. 2, the top side of the lip 14 is substantially planar and forwardly extends to a transverse front edge surface 15 of the lip 14. A spaced series of wear members representatively in the form of adapters 16 are anchored to the lip 14 and have forwardly projecting nose portions 18 to which replaceable excavating tooth points 20 may be removably secured. Lip protector or shield structures 22 are interdigitated with the adapter / point assemblies 16,20 and are removably secured to the lip 14.

[0037] According to key aspects thereof, the present invention provides novel attachment structure and apparatus f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com