Power generation control system, power generation control method, program, and medium

a power generation control and control method technology, applied in process and machine control, electrochemical generators, instruments, etc., can solve the problems of wasting energy each time power-up and power-down operations are performed, preventing the reduction of durability, and stabilizing the operation. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

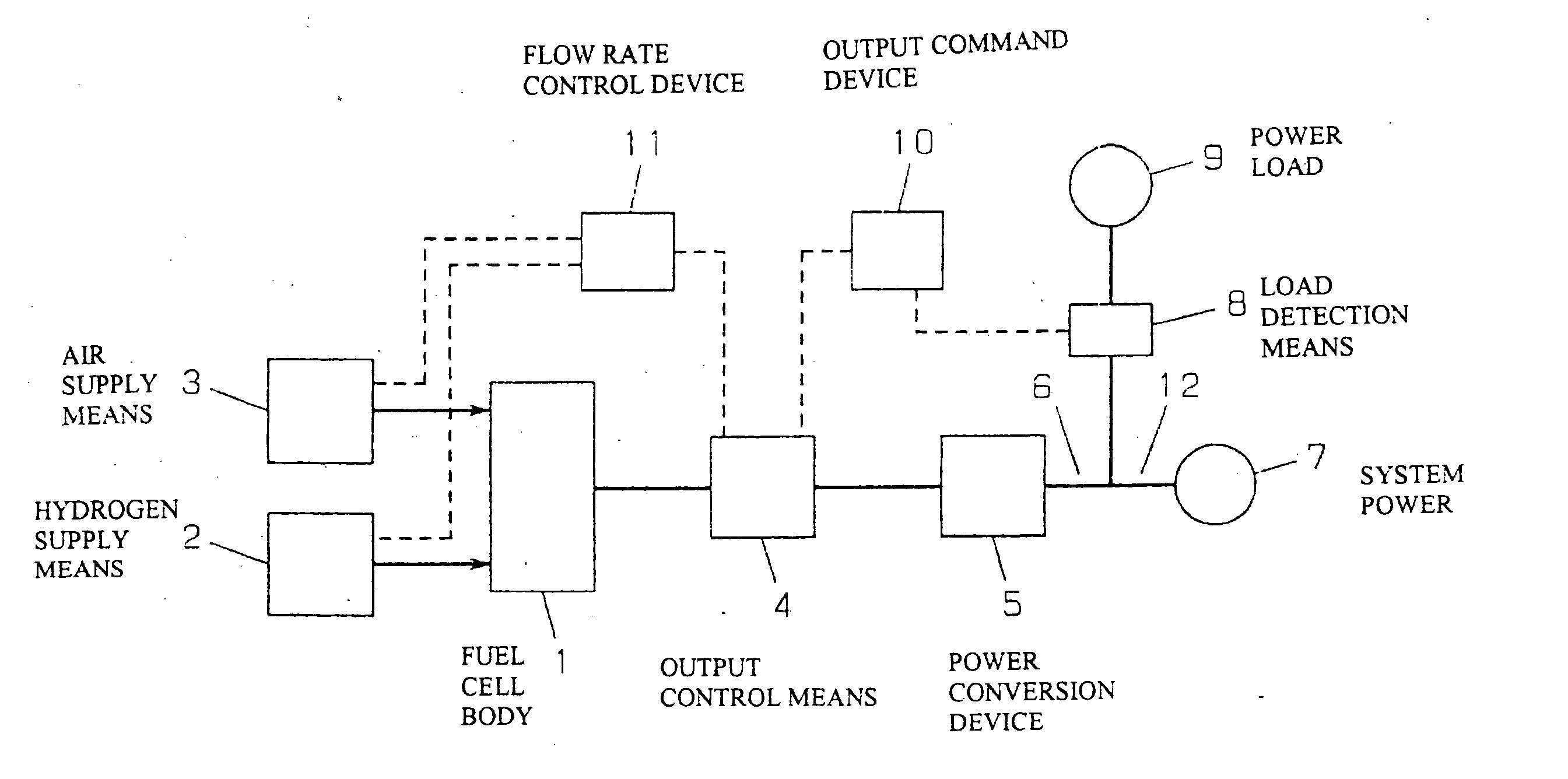

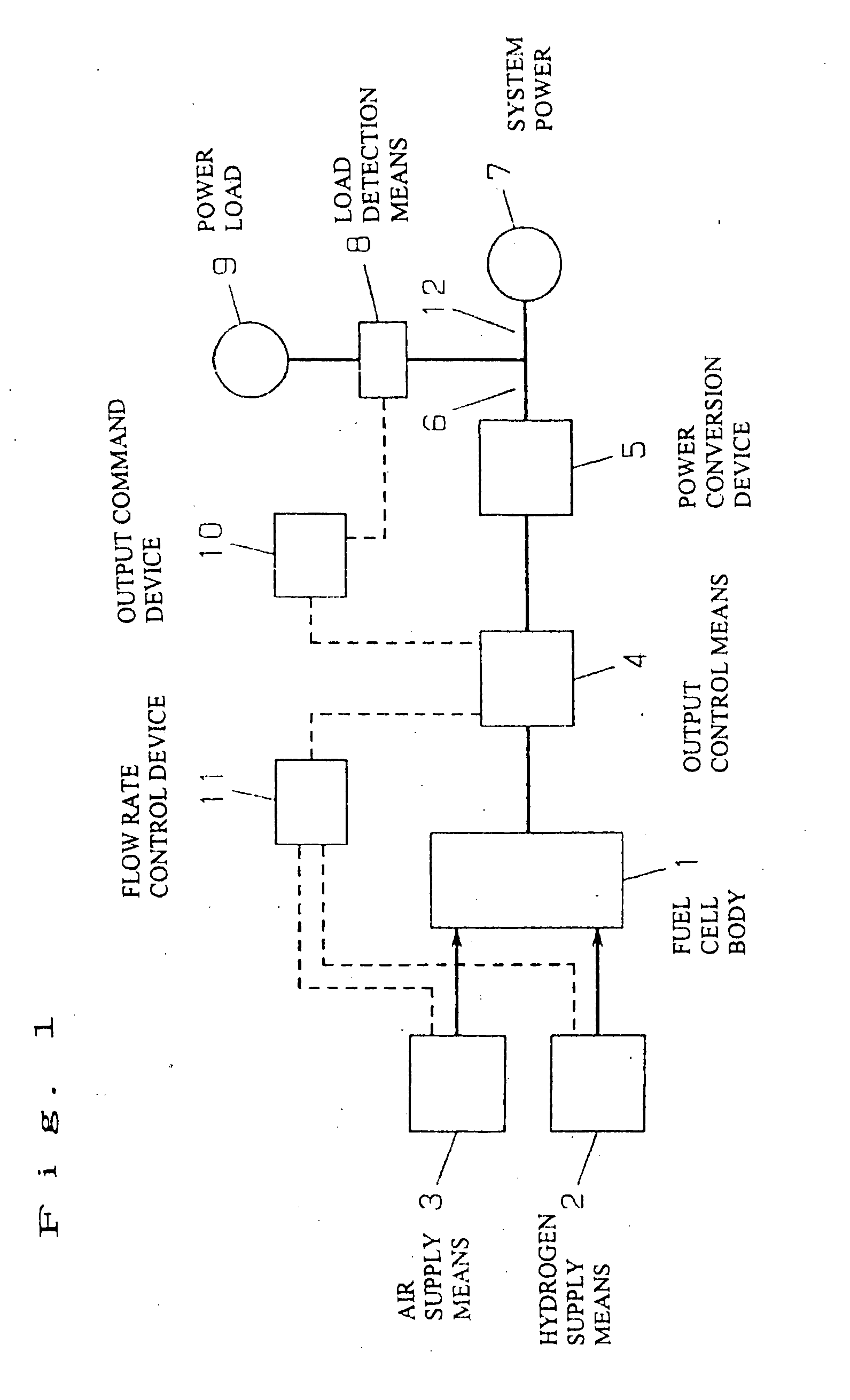

[0159] First, a configuration of a fuel cell power generation device according to a first embodiment of the present invention will be described below by referring to FIG. 1 showing the configuration of the system of the fuel cell power generation device according to the first embodiment of the present invention.

[0160] To a fuel cell body 1, hydrogen supply means 2 represented by a reformer, a hydrogen storage alloy, a hydrogen bomb, etc., and air supply means 3 represented by an air blower, a blower pump, etc. are connected. One terminal of output control means 4 is electrically connected to the fuel cell body 1, and another terminal is electrically connected to a power conversion device 5. An output line 6 is electrically connected to the power conversion device 5, branched in the line, one terminal is electrically connected to a system power 7 through a system power connection line 12 while another terminal is electrically connected to load detection means 8 and a power load 9. O...

embodiment 2

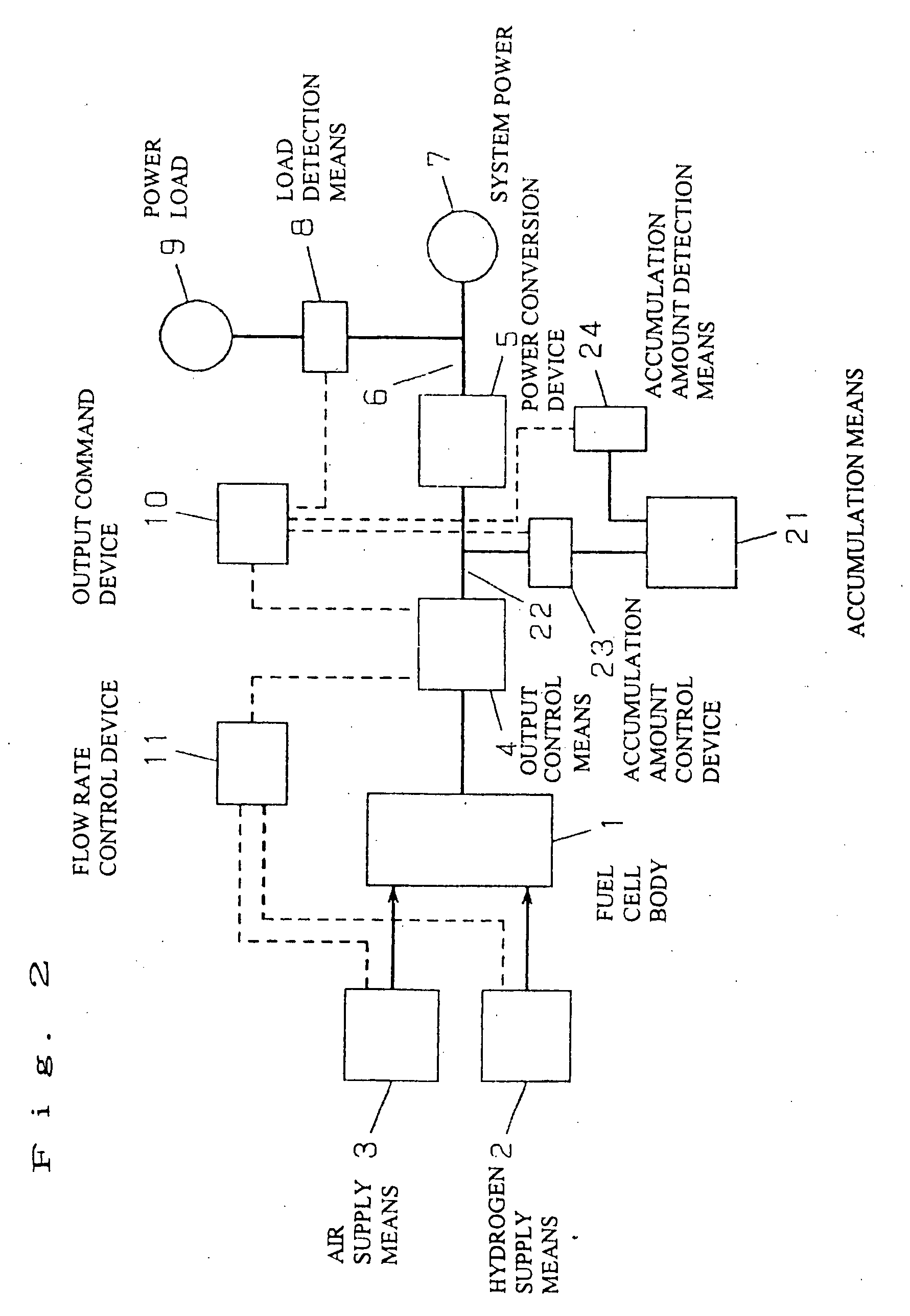

[0170] The configuration of the fuel cell power generation device according to a second embodiment of the present invention will be described below by referring to FIG. 2 showing the configuration of the system of the fuel cell power generation device according to a second embodiment of the present invention. The means also appearing in the above mentioned first embodiment is assigned the same reference numeral, and the explanation is omitted here.

[0171] Accumulation means 21 is branched from a connection line 22 connecting the output control means 4 to the power conversion device 5, and connected through an accumulation amount control device 23. Accumulation amount detection means 24 is connected to the accumulation means 21. An object of providing the accumulation means 21 is to solve the problem with the first embodiment that the economical efficiency is reduced in the system linkage operation by adjusting the power relating to the system power 7 due to the excess or deficient o...

embodiment 3

[0176] Then, the configuration of the fuel cell power generation system according to a third embodiment of the present invention is described below by referring to FIG. 10 showing the configuration of the fuel cell power generation system of the third embodiment of the present invention.

[0177] In FIG. 10, the host 101, output control means 102, and load detection means 103 are serially connected in this order, a load 104 wastes the power connected to the load detection means 103, and a battery 105 is branched and connected from the connection portion between the output control means 102 and the load detection means 103.

[0178] The fuel cell body 101 corresponds to means including the power generation means according to the present invention, the load detection means 103 corresponds to means including the power detection means according to the present invention, the output control means 102 corresponds to means including the power generation control means and the time accumulation m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com