Foldover packages and manufacturing and test methods therefor

a technology of microelectronic elements and packaging, applied in the direction of packaging goods, semiconductor/solid-state device details, containers, etc., can solve the problems of high stress level in the adhesive, premature failure of the bond between the adhesive and the tape run, or premature failure of the bond between the adhesive and the die, etc., to reduce the reliability of the package and high stress level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

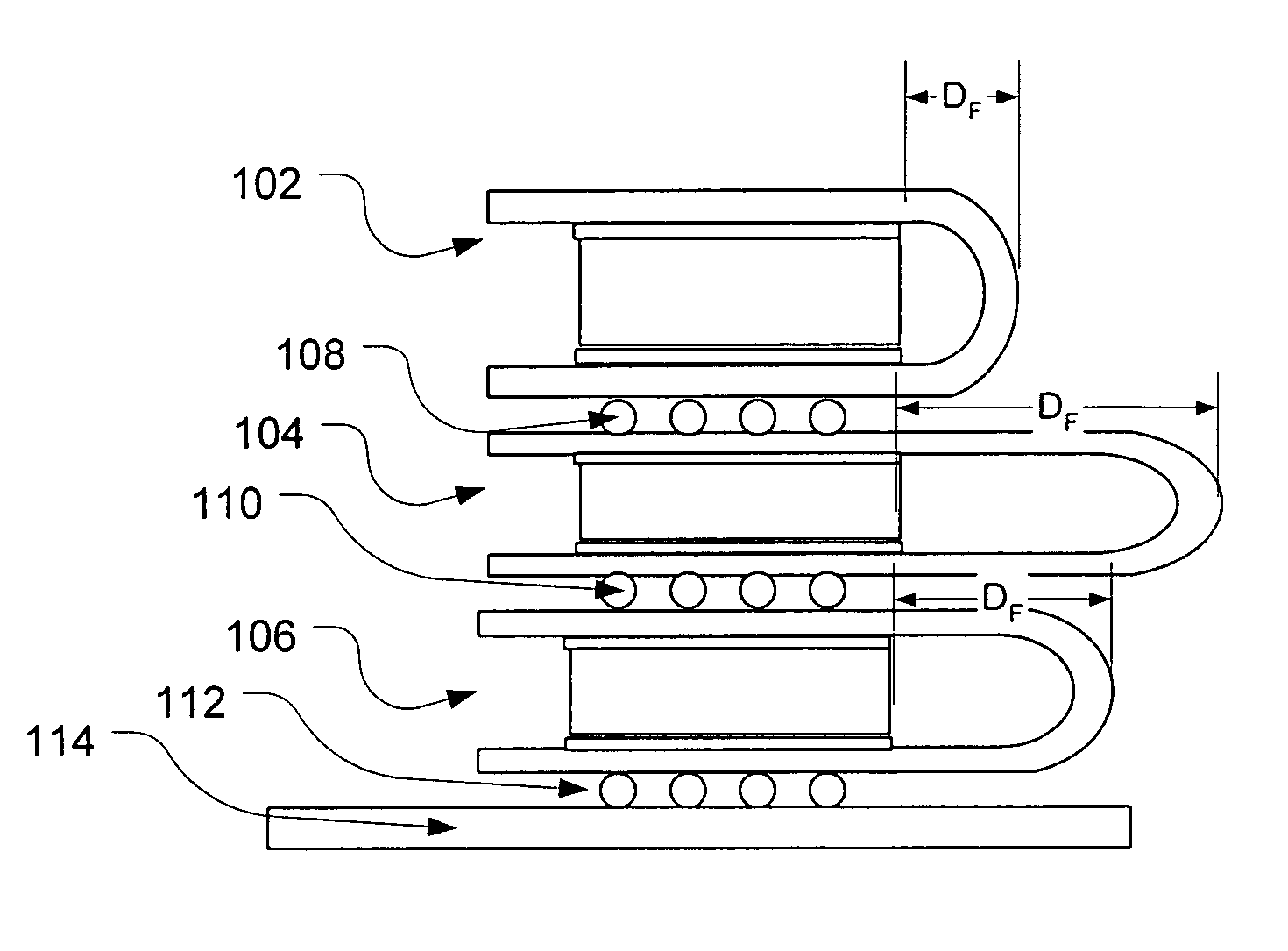

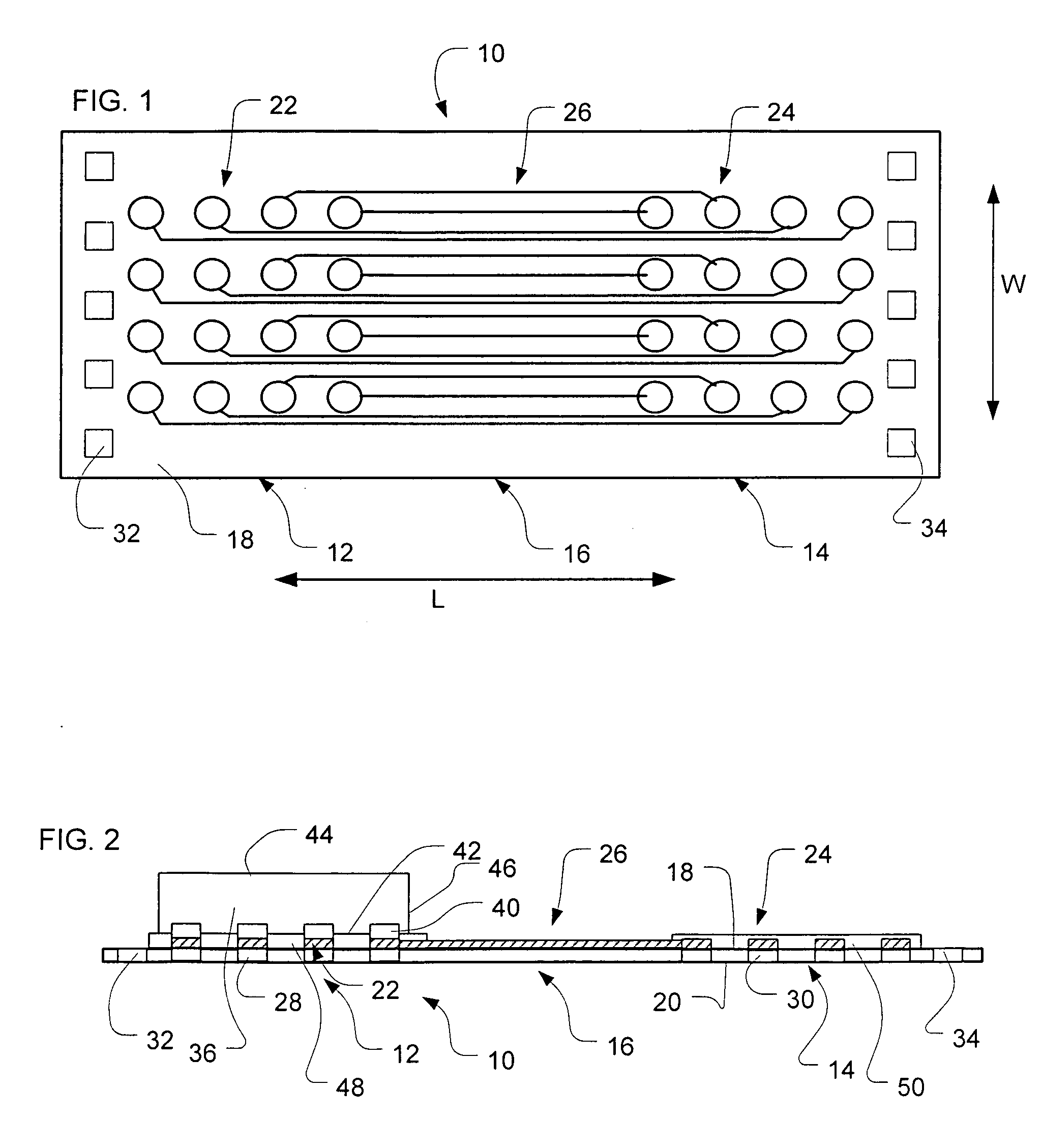

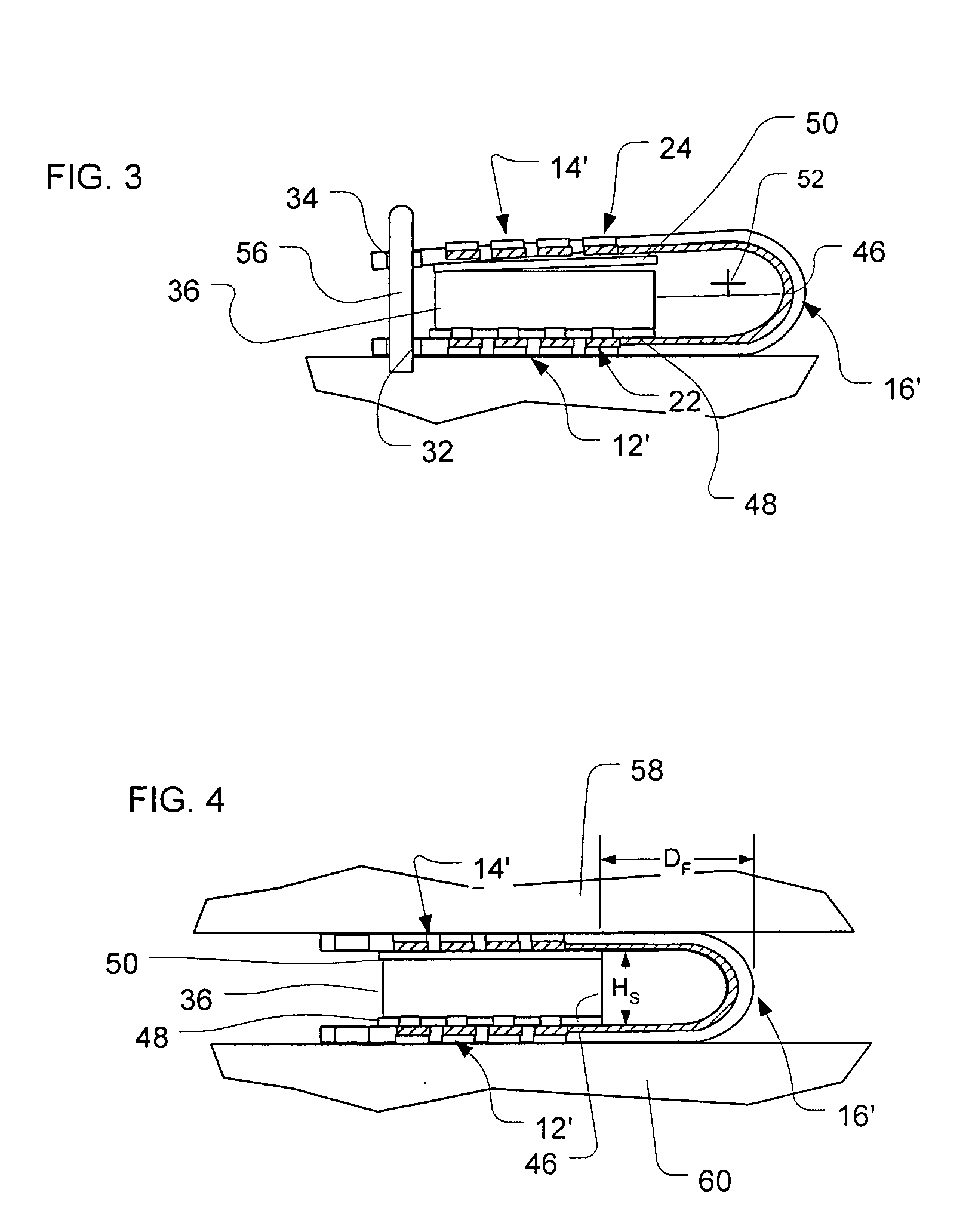

[0023] A process in accordance with one embodiment of the invention utilizes a tape 10 having a first mounting region 12, a second mounting region 14 and a fold region 16 disposed between these end regions. The term “lengthwise direction” is used herein as referring to the direction along the tape between mounting regions 12 and 14, i.e., the direction L from one mounting region to the other across fold region 16. The “widthwise direction” as referred to herein is the direction transverse to the lengthwise direction. Although the terms lengthwise and widthwise are used herein as referring to these directions, this does not imply that the dimension of the tape in the lengthwise direction L must be greater than the dimension of the tape in the widthwise direction.

[0024] The tape includes a dielectric layer having an inner side 18, visible in FIG. 1, and an opposite, outer side 20 (FIG. 2). The dielectric layer may be formed from any material suitable for forming a circuit panel and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com